Salt-resistant and shear-resistant polymer surfactant for profile control and flooding, and preparation method thereof

A surfactant and polymer technology is applied in the field of composition and preparation of polymer surfactants for salt resistance, shear resistance and flood control, and achieves the effects of improving and reducing the surface tension of oil and water, good oil displacement, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

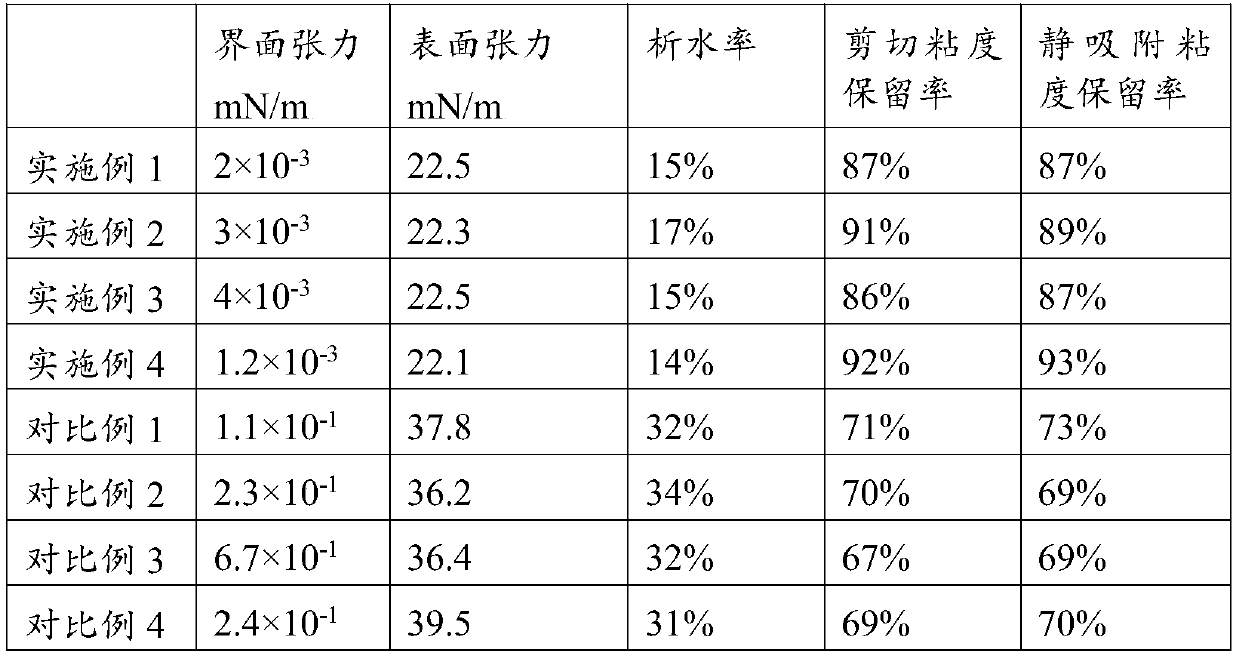

Examples

Embodiment 1

[0028] A kind of anti-salt and anti-shear regulating and flooding macromolecule surfactant, its composition and the mass percentage of various compositions are as follows:

[0029] Cationic polyacrylamide resin (Henan Gaoyuan Water Purification Material Co., Ltd.) 81.2kg

[0030] Gemini quaternary ammonium salt (China Daily Chemical Institute) 1.8kg

[0031] Polyoxyethylene copolymer resin with a molecular weight of 5 million (Sanobang) 3.5kg

[0032] Sodium Acrylamido Alkyl Sulfonate (CAS.38193-60-1) 6.3kg

[0033] Nonionic alcohol ether carboxylate (CAS 132-32-1) 3.4kg

[0034] Ammonium persulfate (CAS No.: 7727-54-0) 0.1kg

[0035] Heptahydroxy chelating agent (CAS: 134-31-6) 0.16kg

[0037] Wherein, the gemini quaternary ammonium salt is myristyl gemini quaternary ammonium salt, and the polyoxyethylene copolymer resin is fatty alcohol polyoxyethylene ether. Preparation method: Add 81.2kg of cationic polyacrylamide resin, 1.8kg of gemini...

Embodiment 2

[0040] A kind of anti-salt and anti-shear regulating and flooding macromolecule surfactant, its composition and the mass percentage of various compositions are as follows:

[0041] Anionic polyacrylamide resin (Henan Gaoyuan Water Purification Material Co., Ltd.) 78.2kg

[0042] Gemini quaternary ammonium salt (China Daily Chemical Institute) 1kg

[0043] Polyoxyethylene copolymer resin (Sainobang) 2.2kg

[0044] Sodium acrylamido-2-methylsulfonate (CAS.15214-89-8) 6.5kg

[0045] Oleamide (CAS:301-02-0) 3.5kg

[0046] Potassium persulfate (CAS: 7727-21-1) 0.2kg

[0047]Phenolic resin (CAS: 9003-35-4) 0.6kg

[0048] Anhydrous Potassium Carbonate 7.3kg

[0049] Wherein, the gemini quaternary ammonium salt is cetyl gemini quaternary ammonium salt, and the polyoxyethylene copolymer resin is fatty alcohol polyoxyethylene ether.

[0050] Preparation method: Add the above formula ingredients into a 500L kneading stainless steel kneader, condense and react at a constant temperat...

Embodiment 3

[0053] A kind of anti-salt and anti-shear regulating and flooding macromolecule surfactant, its composition and the mass percentage of various compositions are as follows:

[0054] Nonionic polyacrylamide resin (Henan Gaoyuan Water Purification Material Co., Ltd.) 80.5kg

[0055] Gemini quaternary ammonium salt (China Daily Chemical Institute) 1.5kg

[0056] Polyoxyethylene copolymer resin (Sainobang) 2.5kg

[0057] Sodium fatty alcohol polyoxyethylene ether sulfonate (CAS:6969-49-9) 4.6kg

[0058] Alkanolamide (CAS: 107628-04-6) 4.0kg

[0059] Sodium bisulfite (CAS:7631-90-5) 0.1kg

[0060] Resorcinol (CAS: 108-46-3) 0.3kg

[0061] Sodium chloride 7.2kg

[0062] Wherein, the gemini quaternary ammonium salt is hexadecyl gemini quaternary ammonium salt, and the polyoxyethylene copolymer resin is polyoxyethylene α-pyrrolidone PVP-35.

[0063] Preparation method: firstly add the above formula ingredients into a 500L kneading stainless steel kneader, condense and react at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com