Temperature-resistant and salt-resistant oil displacement agent for offshore thickened oil steam injection accompanying, and application thereof

A technology of temperature resistance, salt resistance, oil displacement agent, applied in the direction of chemical instruments and methods, drilling composition, etc. Tension and other problems, to achieve good emulsification and viscosity reduction performance, reduce oil-water interfacial tension, and promote the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

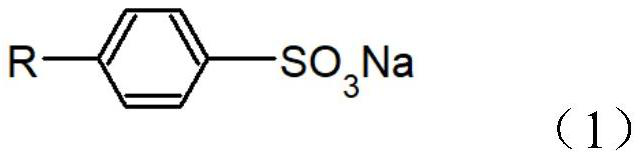

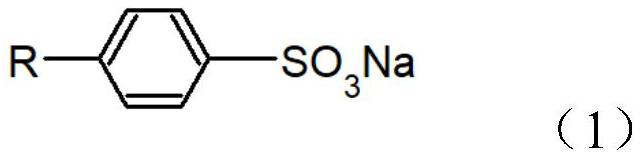

[0036] The mass percentage composition of raw material is as follows:

[0037] Sodium dodecylbenzenesulfonate 0.2%, sodium nonylphenol polyoxyethylene ether carboxylate 0.1%, sodium metaborate 0.05%, water 99.65%, water salinity 1000mg / L;

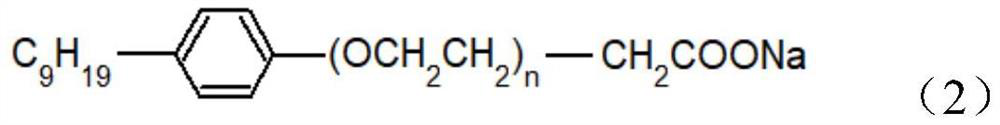

[0038] Among them, the molecular formula of nonylphenol polyoxyethylene ether carboxylate sodium APEC-4 is:

[0039]

[0040] Prepare as follows:

[0041] 1) Add nonylphenol polyoxyethylene ether carboxylate sodium APEC-4 represented by formula (1-1) into water, stir and dissolve to obtain mixture A;

[0042] 2) adding sodium dodecylbenzenesulfonate to the mixture A obtained in step 1), and stirring until dissolved to obtain mixture B;

[0043] 3) Add sodium metaborate into the mixture B obtained in step 2), stir and dissolve to obtain a temperature-resistant and salt-resistant oil-displacement agent.

Embodiment 2

[0045] The mass percentage composition of raw material is as follows:

[0046] 0.3% sodium tetradecylbenzene sulfonate, 0.15% sodium nonylphenol polyoxyethylene ether carboxylate, 0.05% sodium bicarbonate, 99.5% water, the salinity of water is 5000mg / L;

[0047] Among them, the molecular formula of nonylphenol polyoxyethylene ether carboxylate sodium APEC-6 is:

[0048]

[0049] Prepared according to the method in Example 1.

Embodiment 3

[0051] The mass percentage composition of raw material is as follows:

[0052] 0.45% sodium cetylbenzenesulfonate, 0.15% sodium nonylphenol polyoxyethylene ether carboxylate, 0.1% sodium metaborate, 99.3% water, the salinity of water is 10000mg / L;

[0053] Among them, the molecular formula of nonylphenol polyoxyethylene ether carboxylate sodium APEC-10 is:

[0054]

[0055] Prepared according to the method in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com