Flowering cotton strengthening treatment method

A technology of intensive treatment and early flowering, which is applied in the field of textile fiber processing, can solve the problems of flowering cotton strength reduction, limited use range, environmental pollution, etc., and achieve the effects of improving grades, eliminating aging and hardening, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

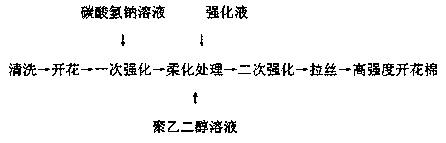

Method used

Image

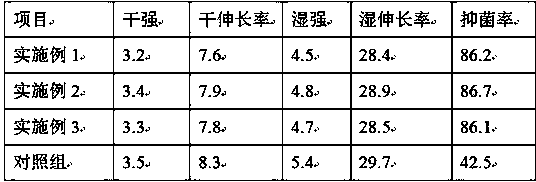

Examples

Embodiment 1

[0024] A method for strengthening flowering cotton, comprising the following steps:

[0025] Put waste cotton products in washing powder solution, ultrasonically clean them at 45°C and 28kHz for 50 minutes, then rinse them with clean water, repeat the ultrasonic cleaning twice, take them out after each ultrasonic cleaning, rinse them with clean water, and place them in the new preparation again. Ultrasonic in the washing powder solution, drying, the temperature is 45 ℃, and drying until the water content is 10-15%, fully remove the stains in waste cotton products, facilitate post-processing, improve the whiteness of flowering cotton, and obtain Clean the cotton; then use the flowering machine to carry out flowering treatment on the cleaned cotton, so that the post-treatment is more fully and evenly obtained, and the first flowering cotton is obtained; then the first flowering cotton is soaked in a sodium bicarbonate solution with a mass percentage concentration of 3 to 4%, and ...

Embodiment 2

[0027] A method for strengthening flowering cotton, comprising the following steps:

[0028] Put waste cotton products in washing powder solution, ultrasonically clean them at 50°C and 29kHz for 55 minutes, and then rinse them with clean water. Repeat the ultrasonic cleaning twice. Ultrasonic in the washing powder solution, drying, the temperature is 48 ℃, drying to a water content of 10-15%, fully remove the stains in waste cotton products, facilitate post-processing, improve the whiteness of flowering cotton, and obtain Clean the cotton; then use the flowering machine to perform flowering treatment on the cleaned cotton to make the post-treatment more fully and evenly, and obtain the first-flowered cotton; then soak the first-flowered cotton in a sodium bicarbonate solution with a mass percentage concentration of 3.5%, and adjust to a vacuum state, soak at room temperature for 11 hours, take it out, and wash it with clean water, so that the flowering cotton will undergo a sl...

Embodiment 3

[0030] A method for strengthening flowering cotton, comprising the following steps:

[0031] Put the waste cotton products in the washing powder solution, ultrasonically clean them at 55°C and 30kHz for 60 minutes, then rinse them with clean water, repeat the ultrasonic cleaning three times, take them out after each ultrasonic cleaning, rinse them with clean water, and place them in the new preparation again. Ultrasonic in the washing powder solution, drying, the temperature is 50 ℃, drying to a water content of 10-15%, fully remove the stains in waste cotton products, facilitate post-processing, improve the whiteness of flowering cotton, and obtain Wash the cotton; then use the flowering machine to perform flowering treatment on the cleaned cotton to make the post-treatment more fully and evenly, and obtain the first-flowered cotton; then soak the first-flowered cotton in a sodium bicarbonate solution with a mass percentage concentration of 4%, and adjust to a vacuum state, soa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com