Stainless steel-FRP (fiber reinforced plastic) composite connecting part for sandwich thermal-insulating wall

A fiber-reinforced plastic and thermal insulation wall technology, which is applied in the direction of thermal insulation, walls, building components, etc., can solve the problems of falling off of the outer leaf wall and the connector, poor fire resistance, and low thermal conductivity, so as to improve the thermal insulation effect , thermal insulation performance is good, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

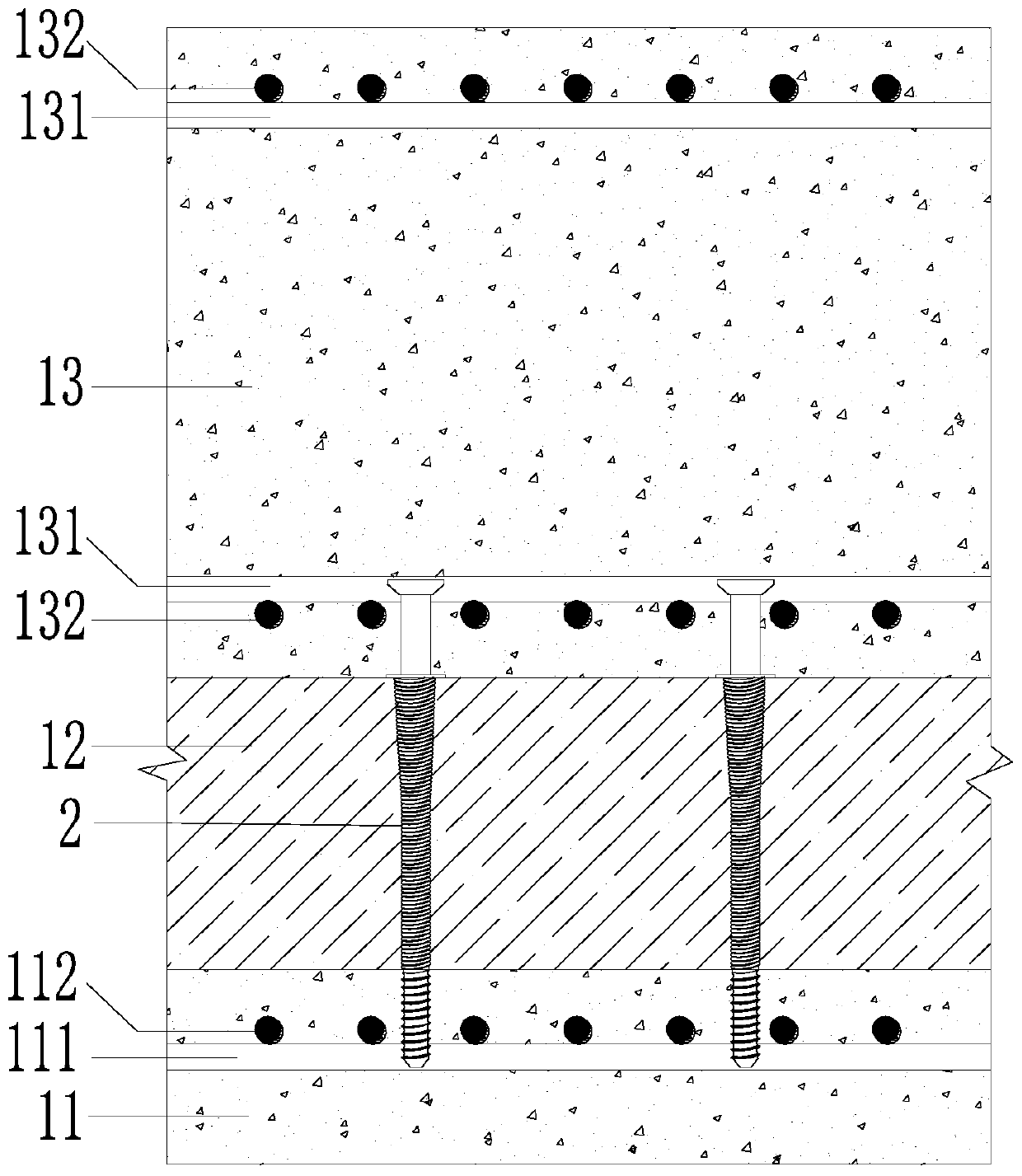

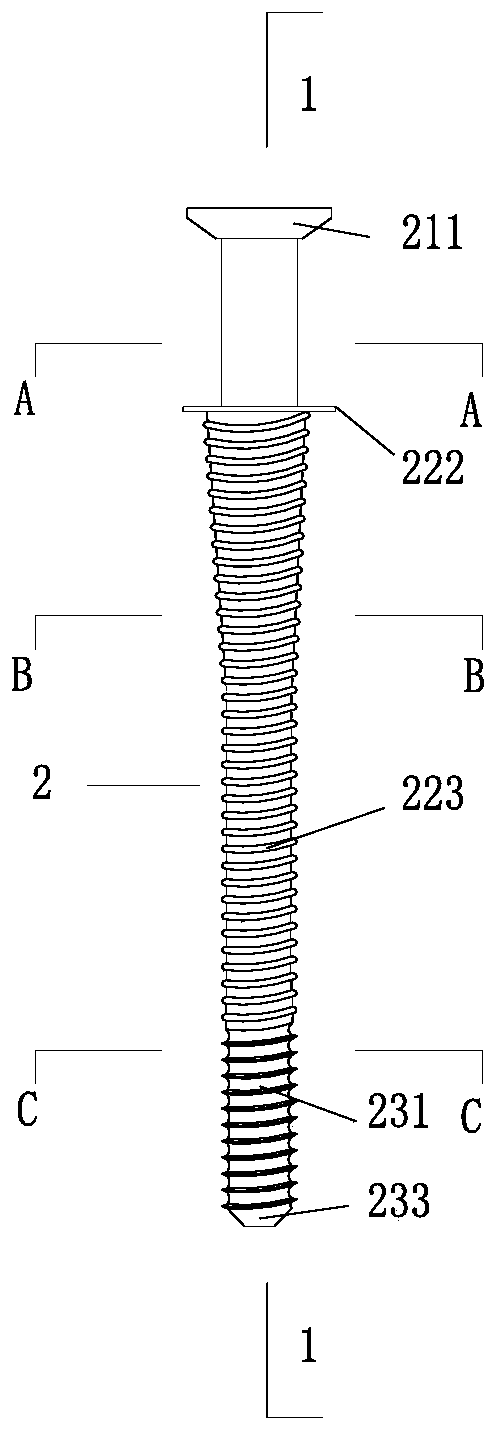

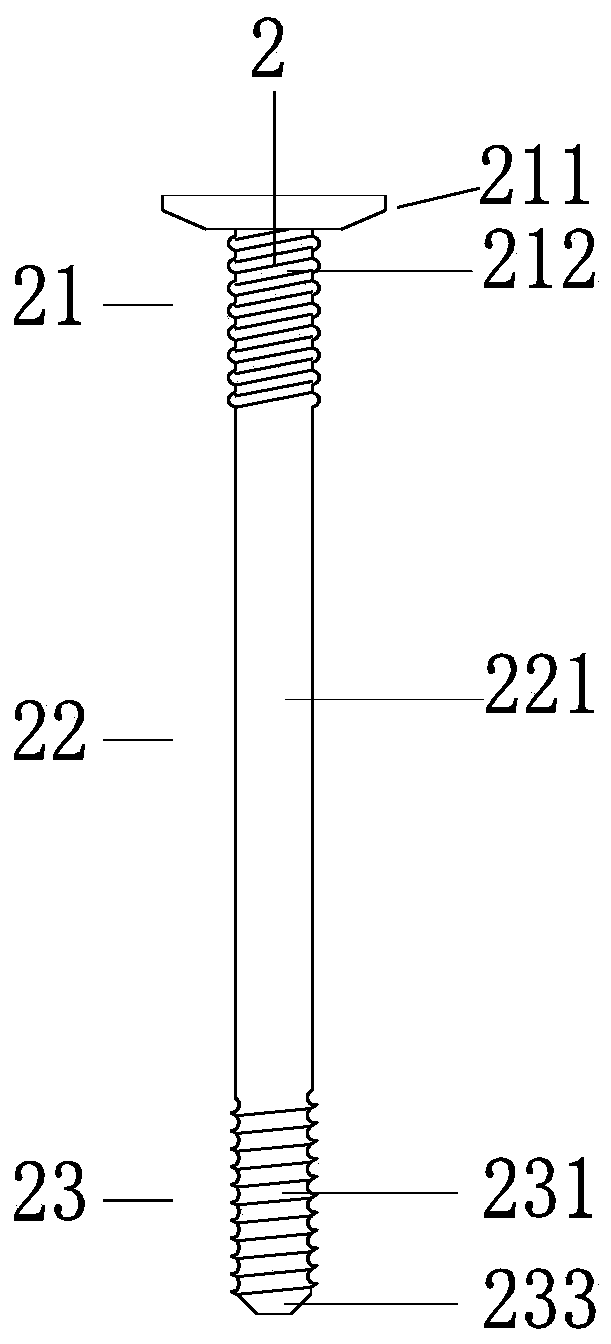

[0036] The prefabricated concrete sandwich insulation exterior wall 1 is composed of a reinforced concrete outer leaf wall 11, a reinforced concrete inner leaf wall 13 and a sandwich insulation layer 12, and the reinforced concrete outer leaf wall 11 and the reinforced concrete inner Leaf wall 13 and sandwich insulation layer 12; the reinforced concrete outer leaf wall 11 includes horizontal distribution bars 111 of the reinforced concrete outer leaf wall, longitudinal distribution bars 112 of the reinforced concrete outer leaf wall, and the reinforced concrete inner leaf wall 13 includes steel bars The horizontal distribution bars 131 of the concrete inner leaf wall, the longitudinal distribution bars 132 of the reinforced concrete inner leaf wall, and the sandwich insulation layer 12 adopt organic insulation boards (such as extruded polystyrene boards or polystyrene boards, etc.), or inorganic insulation boards (rock cotton, etc.), see Figure 1-Figure 8 .

[0037] One end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com