HAp-CSA-SF composite gel material, and preparation method and application thereof

A technology of composite gel and composite gel layer, which is applied in prosthesis, tissue regeneration, medical science, etc., can solve problems such as low support performance, poor toughness, weak cartilage and bone integration, etc., and achieve good effect and high toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In one or more specific embodiments of the present invention, there is provided a preparation method of the above-mentioned HAp-CSA-SF composite gel material.

[0046] Preparation of HAp: mix oleic acid and ethanol, add calcium salt solution, then add lye solution, then add sodium hydrogen phosphate solution, stir, and react at high temperature.

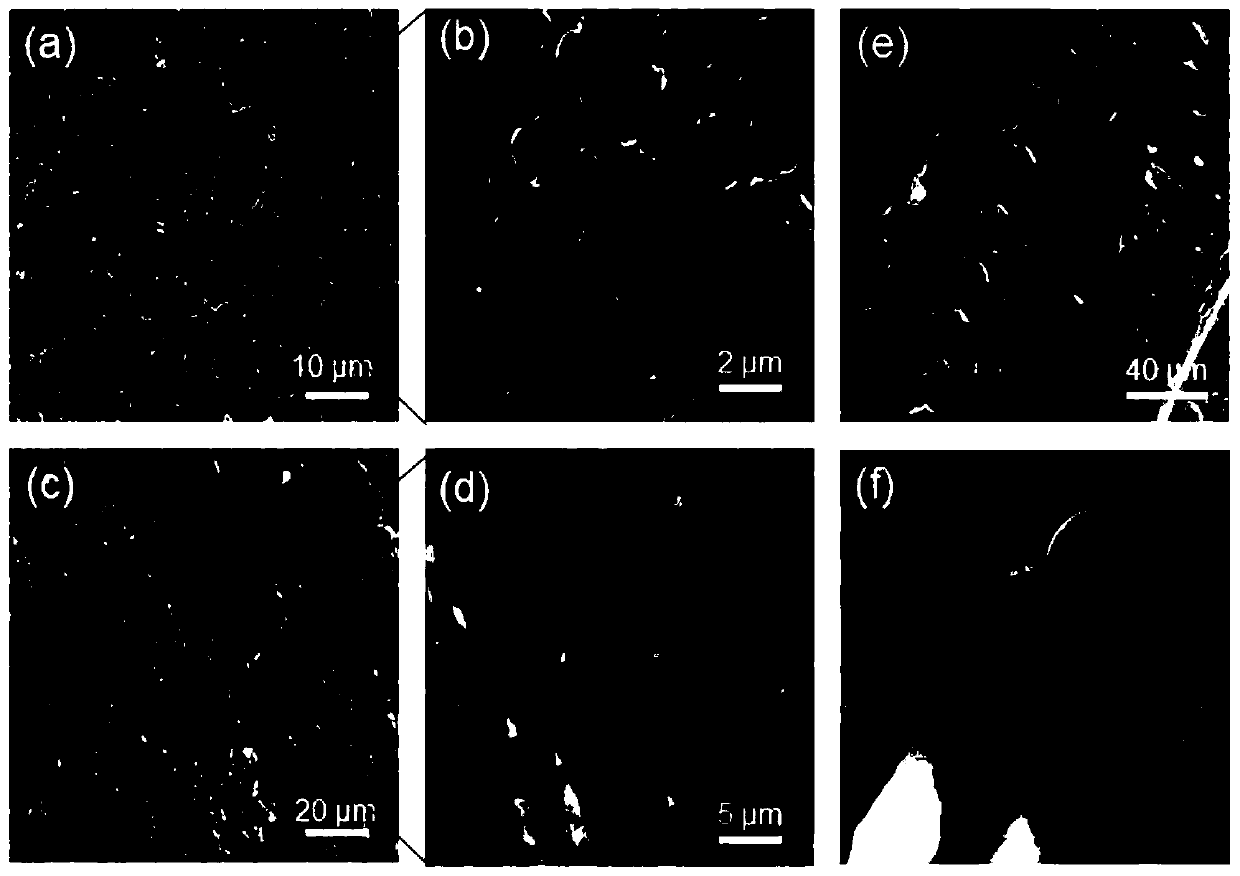

[0047] Preparation of CSA-SF complex acid solution: A silk fibroin formic acid solution was prepared, and chondroitin sulfate was added to the silk fibroin formic acid solution.

[0048] In one or more specific embodiments of the present invention, the preparation method further includes placing the CSA-SF composite mixed acid solution into a mold bearing HAp, and the HAp-CSA-SF composite gel is obtained after the acid solution is volatilized and cooled Material.

[0049] In one or more specific embodiments of the present invention, the preparation method further includes immersing the HAp-CSA-SF composite gel material prepar...

Embodiment

[0065] Experimental materials and methods:

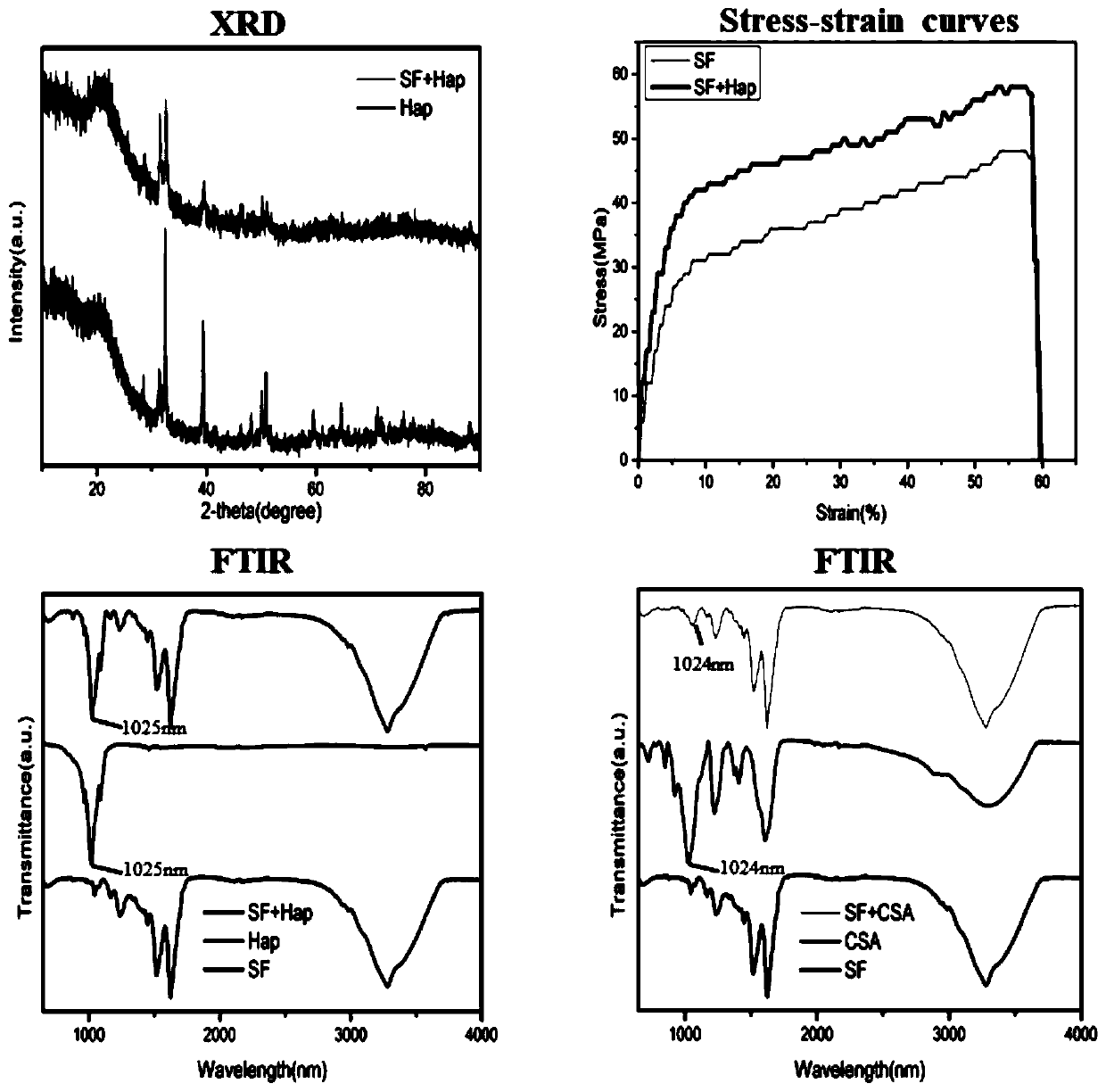

[0066] (1) Preparation and characterization of HAp-CSA-SF high toughness gel material

[0067] 1. Degumming will 2.55g anhydrous NaCO 3 Add to boiled deionized water, wait for complete dissolution, pour 3g of the chopped silkworm shell into it, stir and heat for 30min, take out the degummed silk, wash it with deionized water for 2 to 3 times, soak it overnight, take it out, room temperature Let dry.

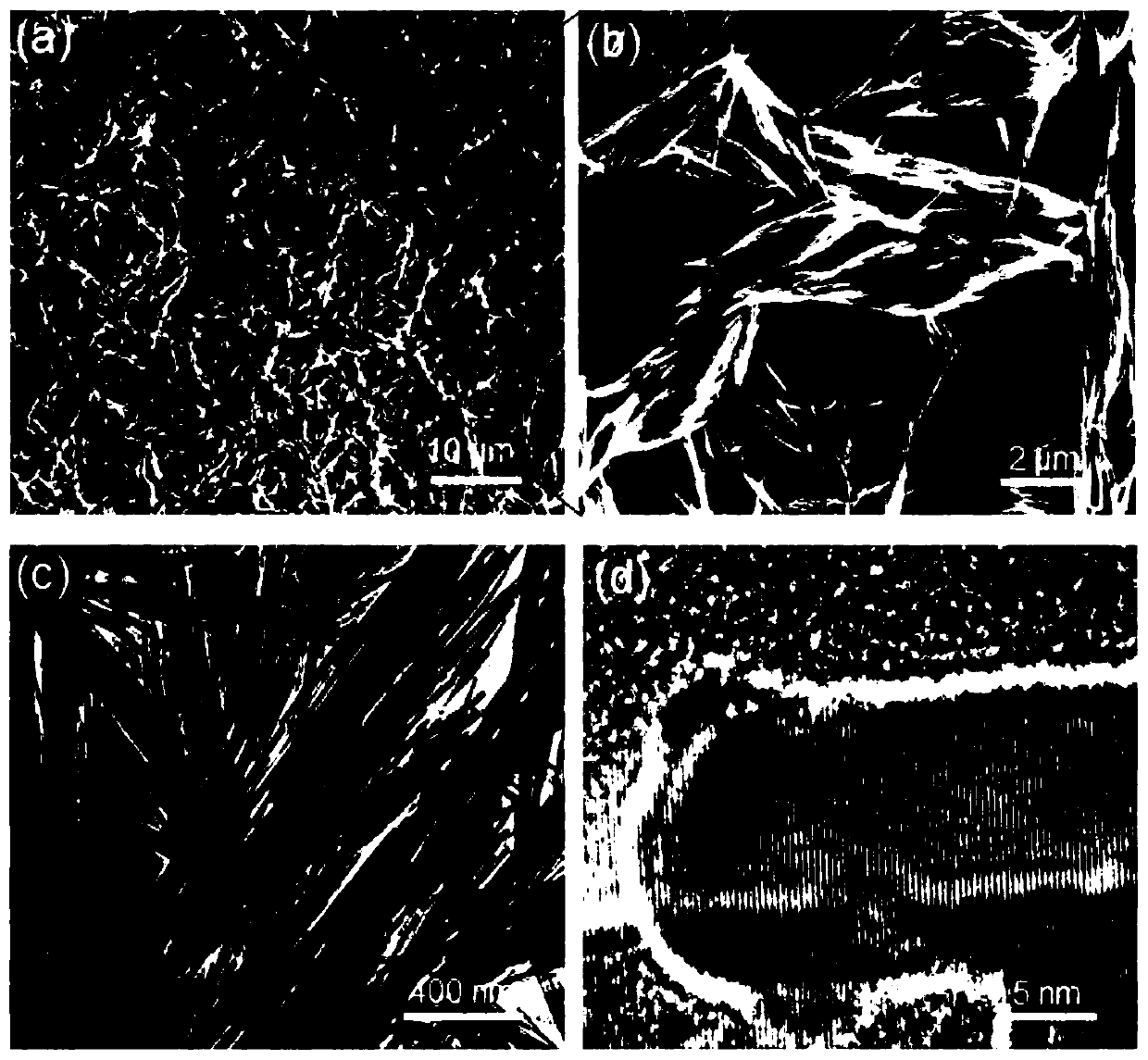

[0068] 2. Preparation of HAp short nanowires

[0069] First mix 8ml oleic acid and 10ml absolute ethanol, then add 147mg CaCl 2 ·2H 2 Aqueous O (6ml) followed by 0.5g aqueous NaOH (8ml) followed by 156mg NaH 2 PO 4 ·2H 2 Aqueous O solution (4 ml), stirred for 10 min. Finally, the reaction was carried out in an oven at 180 °C for 12 h. After washing with absolute ethanol, HAp short nanowires were obtained.

[0070] 3. Dissolve Weigh 0.2~1g anhydrous calcium chloride, dissolve it in 10~15ml 88% formic acid, add 1~2g silk in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com