A tubular micro-mixer and its continuous preparation method for azo pigments

A micro-mixer and azo pigment technology, applied in the direction of azo dyes, monoazo dyes, chemical instruments and methods, etc., can solve the problem of large-scale, long-term pigment production, narrow micro-reactor mixing channels, It is difficult to clean the reactor and other problems, and achieve the effect of suppressing local overheating, improving reaction yield and product performance, and shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

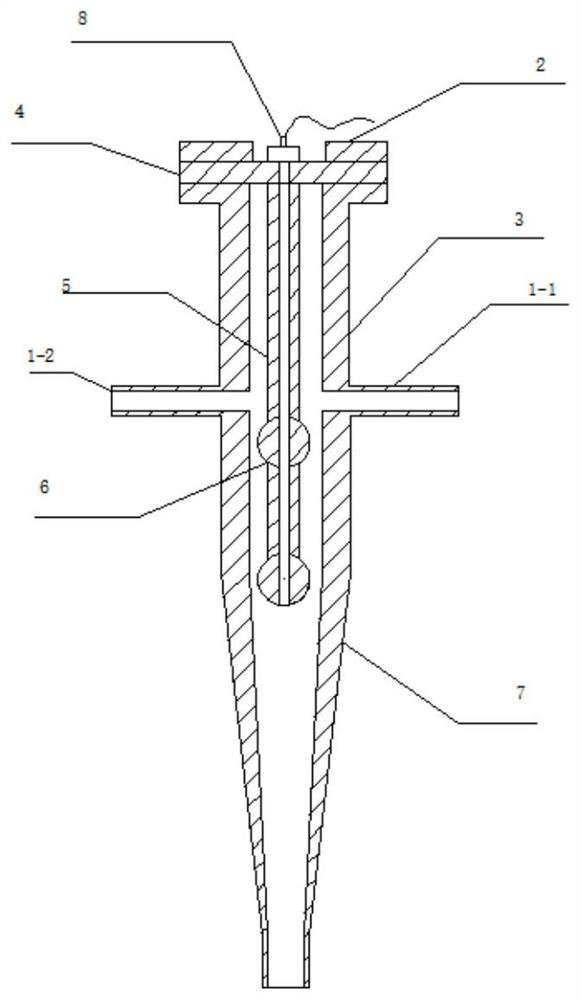

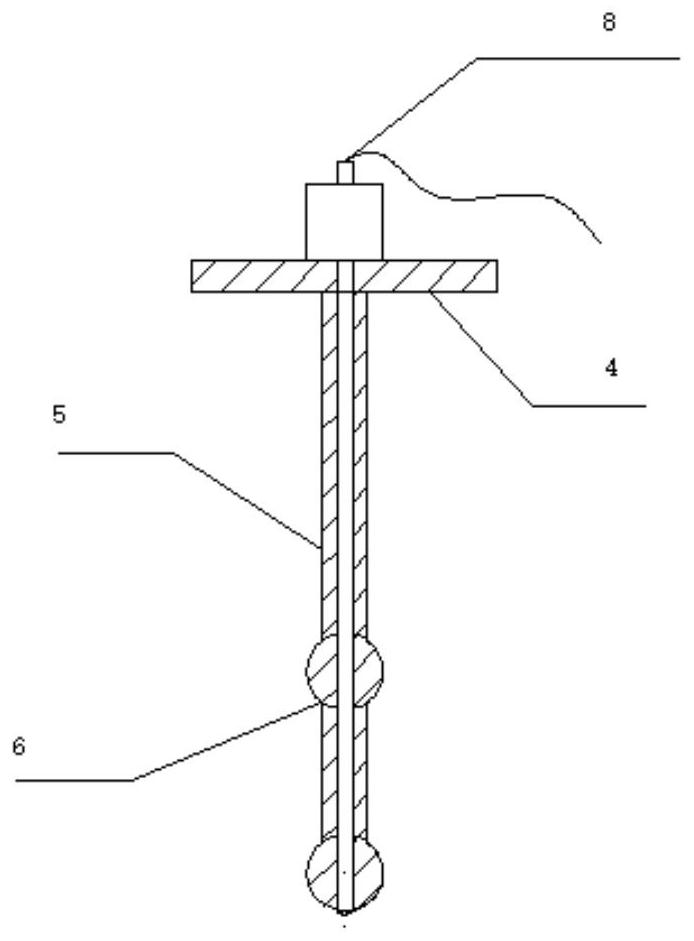

[0039] A tubular micro-mixer, comprising a top cover 2, a cylinder body 3, and an outlet channel 7; the top cover 2 is tightly connected to the top of the cylinder body 3 in the form of a flange, and the length of the cylinder body 3 is 120mm, and the inner diameter The outlet channel 7 is coaxially connected to the bottom of the cylinder 3, and the inner diameter and outer diameter of the outlet channel 7 gradually decrease from top to bottom; the side wall of the cylinder 3 is provided with a second A feed port 1-1 and a second feed port 1-2, the first feed port 1-1 and the second feed port 1-2 are arranged oppositely, the length between the ports of the two feed ports The inner diameter of the two feeding ports is 90mm, and the inner diameter of the two feed ports is 4mm. The top cover 2 and the top of the cylinder body 3 are sealed by a flange gasket 4; a spoiler bar 5 is arranged at the center of the flange gasket 4, and the The spoiler rod 5 extends toward the outlet pas...

Embodiment 2

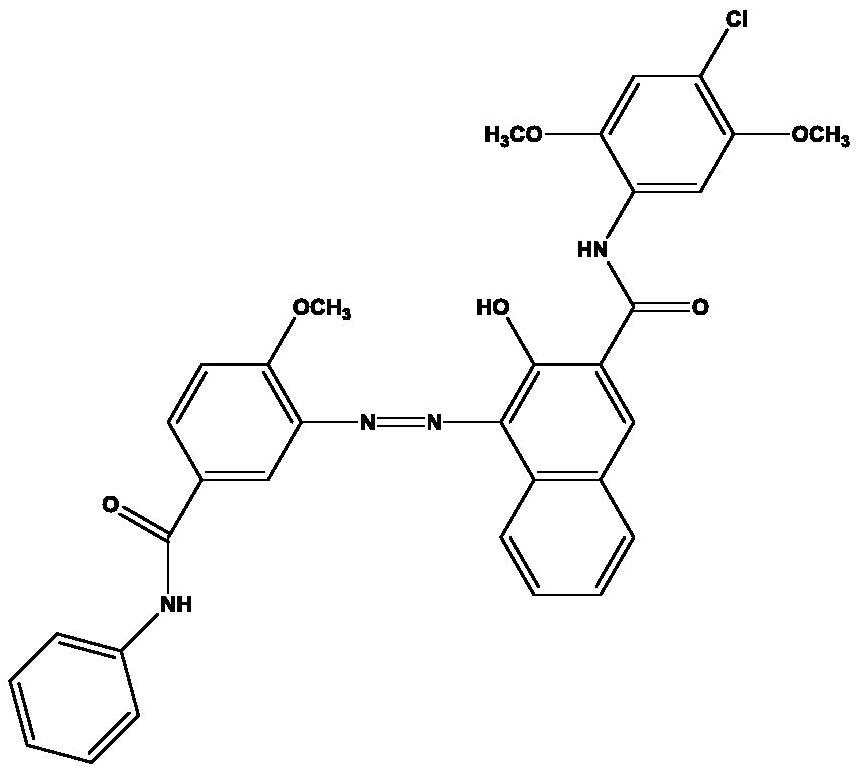

[0041] Preparation of Pigment Red 146 Compound by Continuous Process

[0042] Both the continuous diazotization reaction and the coupling reaction use the tubular micro-mixer in Example 1

[0043] Add 800mL of ice water, 30ml of 37% concentrated hydrochloric acid and 25.47g of 3-amino-4-methoxy-N-phenylbenzamide (red base KD) into a 2L beaker successively. Add water to make up the total volume of the suspension to 1 L, beat for 60 minutes to prepare 3-amino-4-methoxy-N-phenylbenzamide slurry, and cool to 0°C.

[0044] Add 800mL of ice water and 12.35g of sodium nitrite into a 2L beaker, stir until completely dissolved, dilute with water until the total volume of the solution is 1L to prepare a sodium nitrite solution, and cool to 0°C.

[0045] Transfer the above-mentioned 3-amino-4-methoxy-N-phenylbenzamide slurry and sodium nitrite solution to two storage tanks respectively, and use a calibrated metering pump to adjust the The flow rates of the oxy-N-phenylbenzamide slurry ...

Embodiment 3

[0056] Preparation of Pigment Yellow 12 Compound (Benzidine Yellow G, C.I.Pigment Yellow 12)

[0057] Both the continuous diazotization reaction and the coupling reaction use the tubular micro-mixer in Example 1

[0058] In a 2L beaker, add 1L of ice water, 140ml of 37% concentrated hydrochloric acid and 105g of 3,3'-dichlorobenzidine hydrochloride (DCB hydrochloride) successively. Add water to make up the total volume of the suspension to 1.5L, beat for 60 minutes to prepare 3,3'-dichlorobenzidine slurry, and cool to 0°C.

[0059] Add 1L of ice water and 55g of sodium nitrite into a 2L beaker, stir until completely dissolved, dilute with water until the total volume of the solution is 1.5L to prepare a sodium nitrite solution, and cool to 0°C.

[0060] Transfer the above 3,3'-dichlorobenzidine slurry and sodium nitrite solution to two storage tanks respectively, and use a calibrated metering pump to adjust the 3,3'-dichlorobenzidine slurry and sodium nitrite The flow rates ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com