A kind of method and device for rectifying organosilicon ring mixture

An organosilicon ring and mixture technology, which is applied in the field of ring separation, can solve the problems of poor technical and economic benefits, low main content of D3 products, and influence on the quality of downstream products, so as to achieve easy control of the process flow and overcome serious high-temperature corrosion of equipment. , The effect of production conditions is not harsh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

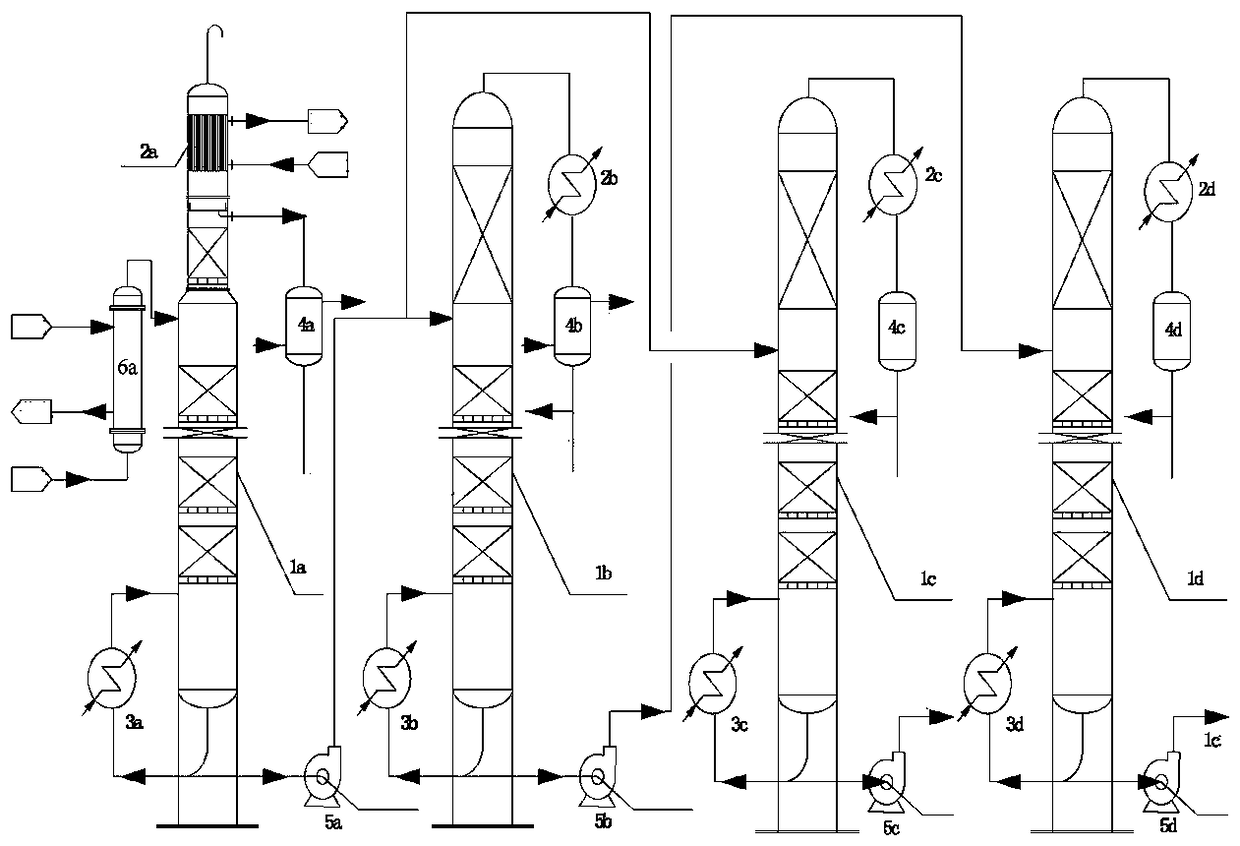

Embodiment 1

[0008] Distillation tower 1 (1a) and reboiler 1 (3a) are fed with heat conduction oil for heating. After the temperature at the top of the tower slowly reaches 137-139°C, reflux for 10 minutes, take a sample from the top of the tower to analyze the D3 content of 97%, and start the rectification tower (1a) Feed pump, adjust the feed rate to 10m³ / h, and preheat to 135°C through the preheater (6a). Open the valve of the top production pipeline, the production volume is 0.5m³ / h, open the regulating valve of the production pipeline in the tower kettle, the production volume is 9.5m³ / h, and the production volume in the tower kettle goes to the rectification tower three (1c), and the rectification tower three (1c ) The top temperature is controlled at 102°C, and the vacuum degree is -0.095MPa to obtain DMC product with D3 content of 0.8%. DMC chromatographic analysis shows that the total amount of impurity peaks that appear before D4 is 7ppm, and the total impurity content is 46ppm. ...

Embodiment 2

[0010] Distillation tower one (1a) and reboiler one (3a) are fed with heat conduction oil for heating. After the temperature at the top of the rectification tower slowly reaches 100-105°C, reflux for 10 minutes, take a sample at the top of the tower to analyze the MM content of 96%, and start the refining process. Distillation column one (1a) feed pump, adjust the feed rate to 15m³ / h, and preheat to 140°C through the preheater (6a). Open the valve of the top production pipeline, the production volume is 0.75m³ / h, open the regulating valve of the production pipeline in the tower kettle, the production volume is 14.25m³ / h, the production volume in the tower kettle goes to the rectification tower three (1c), and the rectification tower three (1c ) The top temperature is controlled at 99-103°C, the vacuum degree is -0.095MPa, the DMC product is extracted from the top, and the chromatographic analysis shows that the content of D3 is 5.0%, the total amount of impurity peaks that appe...

Embodiment 3

[0012] Reboiler 1 (3a) of rectification tower 1 (1a) is fed with heat conduction oil for heating. After the top temperature of rectification tower 1 (1a) rises slowly to 109-111°C, reflux for 10 minutes, take a sample at the top of the tower to analyze the MM content 60%, start the feed pump of the rectification tower, adjust the feed rate to 10m³ / h, and preheat to 140°C through the preheater (6a). Open the top production pipeline valve, the production volume is 0.3m³ / h, open the tower bottom production pipeline regulating valve, the production volume is 9.7m³ / h, the tower bottom production goes to the second rectification tower (1b), the second rectification tower (1b ) The top temperature of the tower is controlled at 83-85°C, the vacuum degree is -0.065MPa to obtain D3 product, the output is 0.4m³ / h, and the D3 content is 98.5%. , the top temperature of the rectification tower four (1d) is controlled at 87-89°C, the vacuum degree is -0.096, and the D4 product is extracted f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com