Acrylamide copolymer, preparation method and applications thereof

A technology of acrylamide copolymer and polymerization reaction, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as poor effect and complex oil-water relationship, and achieve excellent viscosity increase, high surface/interface activity, and economical The effect of oil production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] According to the first aspect of the present invention, the present invention provides a method for preparing an acrylamide copolymer, the preparation method comprising: under solution polymerization conditions, in the presence of an initiator and a surfactant, acrylamide, A monomer mixture consisting of comonomers and reactive monomers is polymerized in water.

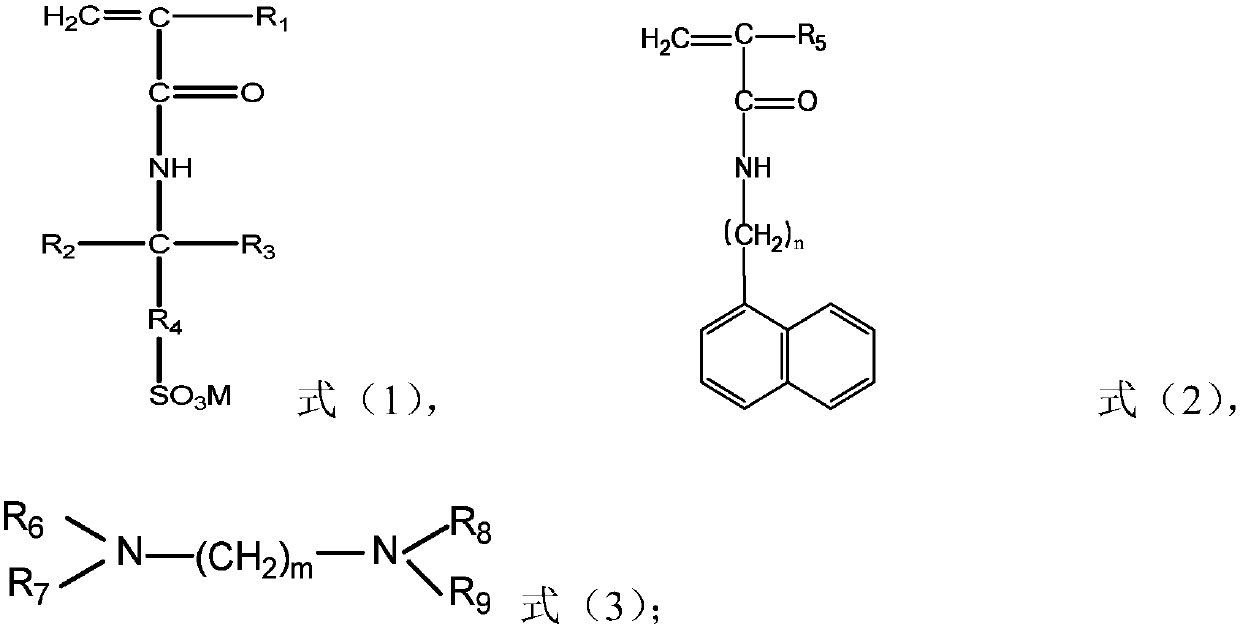

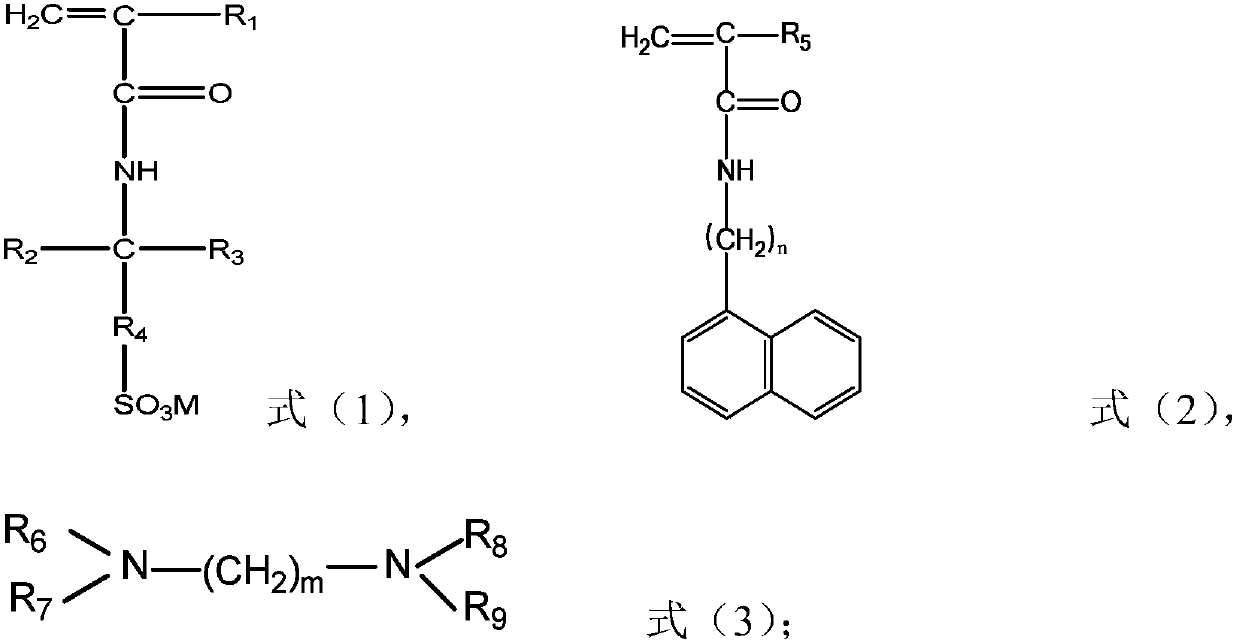

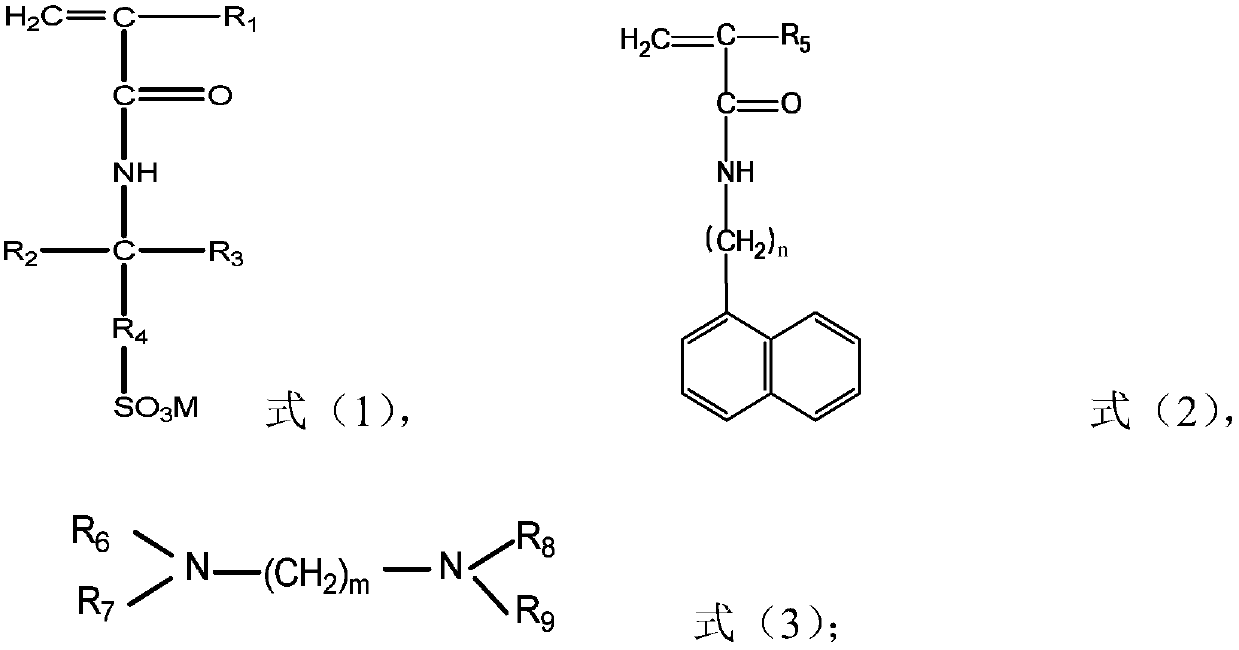

[0016] In the present invention, the structure of the comonomer is as shown in formula (1), and the structure of the active monomer is as shown in formula (2); the initiator includes initiator A and initiator B, and the The structure of initiator A is shown in formula (3), and the initiator B is biuret and / or 1,5-diaminobiuret;

[0017]

[0018] Among them, R 1 -R 3 and R 5 each independently hydrogen or C1-C4 alkyl, R 4 For C1-C4 alkylene, M is hydrogen, sodium or potassium; R 6 -R 9 Each is independently a C1-C4 alkyl group, n is an integer of 1-10, and m is an integer of 2-6.

[0019] In the presen...

Embodiment approach

[0043] According to a more specific preferred embodiment, the preparation method of the acrylamide copolymer comprises the following steps:

[0044] 1) Add acrylamide, comonomer and water into a three-necked flask (hereinafter also referred to as a polymerization bottle) to form an aqueous solution, adjust the pH of the aqueous solution to 6-10 with alkali, and blow nitrogen gas for 20-60 minutes to remove oxygen;

[0045] 2) Under the protection of nitrogen, add the surfactant, the complexing agent aqueous solution, the other auxiliary agents and the active monomer into the aqueous solution, place in a water bath at 25-40°C, stir and disperse evenly, Form stable micelles;

[0046] 3) Under the protection of nitrogen, add initiator A and initiator B to the reaction system of step 2) at a temperature of 25-40°C until the solution becomes thick, that is, the polymerization reaction starts, and the reaction is maintained for 6-8 hour; then the reaction was heated up to 60-70°C, ...

Embodiment 1

[0063] This example is used to illustrate the acrylamide copolymer of the present invention and its preparation method.

[0064] 1) Add 11.8g of acrylamide, 8.0g of 2-acrylamido-2-methylpropanesulfonic acid and 60.0g of deionized water into the polymerization bottle to dissolve the monomer to obtain an aqueous solution of the monomer mixture, which is then oxidized with hydrogen Adjust the pH to 6.0 with sodium, and blow nitrogen gas for 30 minutes;

[0065] 2) under nitrogen protection, add 0.2g sodium lauryl sulfate, 0.2g active monomer (R 5 is methyl, n=1), 0.2g urea and 1.0g EDTA-2Na aqueous solution, put the polymerization bottle in a 25°C water bath, stir and disperse to form stable micelles;

[0066] 3) Under the protection of nitrogen, add 0.01g of N,N,N',N'-tetramethylethylenediamine and 0.002g of biuret into the polymerization bottle at 25°C to initiate polymerization of the monomer mixture and react 6 hour, then warming up to 60°C to continue the polymerization re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com