A kind of modified cellulose fiber and its preparation method and application

A cellulose fiber modification technology, applied in plant fiber, fiber treatment, textiles and paper making, etc., can solve problems such as poor mechanical properties, and achieve the effects of less side reactions, easy realization, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A second aspect of the present invention provides a method for preparing modified cellulose fibers, the method comprising the following steps:

[0045] Step 1. Disperse the cellulose fibers in a solvent.

[0046] According to the present invention, in step 1, the cellulose fibers are added into the solvent, preferably under the condition of stirring, the cellulose fibers are dispersed in the solvent to obtain a dispersion mixture.

[0047] According to the present invention, in step 1, stirring is carried out at room temperature (15-30° C.), and the stirring time is 1-5 hours, more preferably 1-3 hours, for example, 2 hours.

[0048] In the present invention, the furan group-containing compound is used to modify the cellulose fiber, preferably a solvent capable of dissolving the furan group-containing compound.

[0049] According to the present invention, in step 1, the solvent is selected from one or both of chloroform and N,N-dimethylformamide (DMF).

[0050] In the...

Embodiment 1

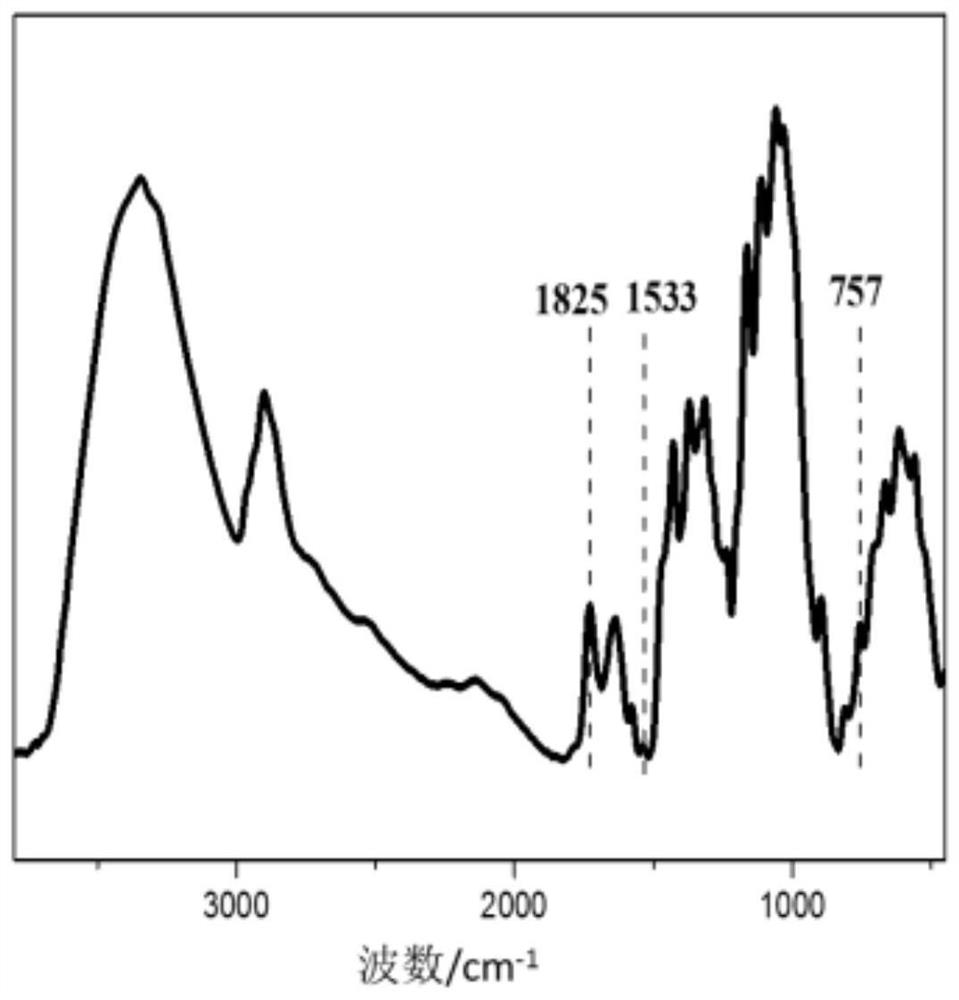

[0109] Embodiment 1 Furoyl chloride modified cellulose fiber

[0110] Take 15.62g of cellulose fibers and 159.48g of chloroform into a 500mL pre-dried round bottom flask, add a magnet, fill with nitrogen and exhaust the air for 2 minutes, seal the bottle, and stir at room temperature for 2 hours until the cellulose fibers are fully dispersed in the chloroform solvent.

[0111] Add 6.43g of furoyl chloride dissolved in 10mL of chloroform and 5.03g of pyridine dissolved in 10mL of chloroform, fill with nitrogen and exhaust the air for 2min, seal the seal, and heat at 70°C for 24h.

[0112] After the reaction, the reaction mixture was placed in a centrifuge tube and centrifuged at 4500 rpm for 10 min to remove chloroform; then 50 mL of chloroform was added to mix thoroughly, and the chloroform was removed by centrifugation. The above process was repeated 3 times. Dry to constant weight to obtain modified cellulose fibers.

Embodiment 2

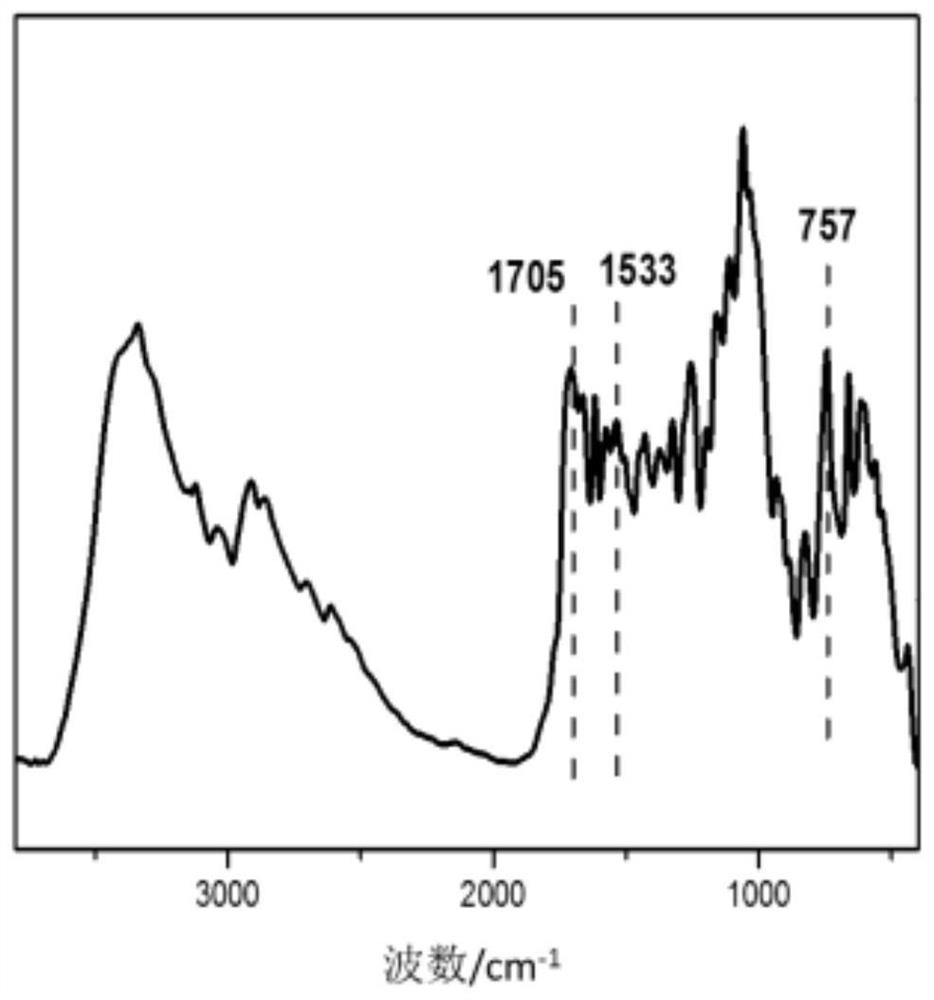

[0113] Embodiment 2 furan methylamine modified cellulose fiber

[0114] Take 17.86g of cellulose fibers and 186.48g of N,N-dimethylformamide into a 500mL pre-dried round-bottomed flask, add magnets, fill with nitrogen and exhaust the air for 2 minutes, seal the seal, and stir at room temperature for 2 hours until the cellulose fibers are in the fully dispersed in chloroform solvent.

[0115] Add 104.58g of N,N-carbonyldiimidazole dissolved in 200mL of N,N-dimethylformamide, inflate with nitrogen and exhaust the air for 2min, then seal, and heat at 60°C for 3h. The container was cooled to room temperature, and 64.32 g of methylfurylamine dissolved in 120 mL of N,N-dimethylformamide was added, and the container was sealed after purging with nitrogen for 2 minutes, and heated at 60°C for 5 hours.

[0116] After the reaction, the reaction mixture was placed in a centrifuge tube and centrifuged at 4500 rpm for 10 minutes to remove N,N-dimethylformamide; then 90 mL of deionized wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com