Biological ink and preparation method thereof

A bio-ink, water-soluble technology, applied in medical science, prosthesis, additive processing, etc., can solve problems such as toxicity and cell damage, achieve mild reaction, promote proliferation and differentiation, and good biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

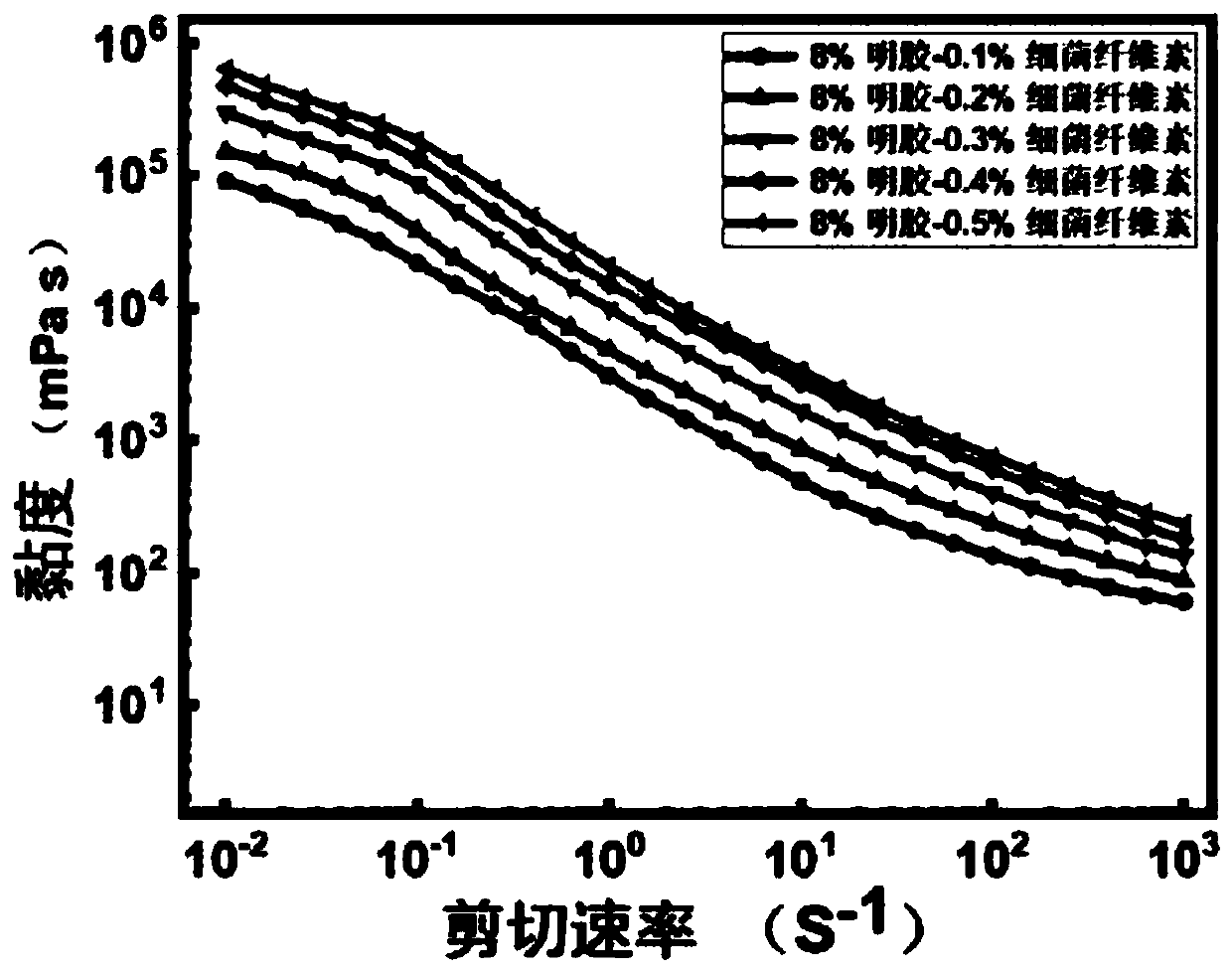

[0042] Embodiment 1 Preparation of bioprinting ink

[0043] (1) The raw materials used in the bio-ink in this example consist of the following, in terms of mass percentage: 8.0% gelatin, 0.1% bacterial cellulose, 0.8% growth factor, 16.7% transglutaminase, and 74.4% sterile PBS solution.

[0044] (2) The preparation steps are as follows:

[0045] 1) Add gelatin, bacterial cellulose, and growth factors to a square petri dish in sequence at 37°C, and irradiate with ultraviolet light for 12-24 hours.

[0046] 2) Add the irradiated gelatin, bacterial cellulose, cell growth factor and sterile PBS solution in 1) into the Shu Niu bottle, and then heat it with magnetic stirring at 30-35°C for 1 hour to dissolve all the components and form a mixture (hydrogel solution).

[0047] 3) Adding counted biological cells into the hydrogel solution to make a suspension.

[0048] 4) Add transglutaminase solution to the suspension.

Embodiment 2

[0049] Embodiment 2 Preparation of bioprinting ink

[0050] (1) The raw materials used in the bio-ink in this example consist of the following components in terms of mass percentage: 8.0% gelatin, 0.2% bacterial cellulose, 0.8% growth factor, 16.7% transglutaminase, and 74.3% sterile PBS solution.

[0051] (2) The preparation method is the same as in Example 1 of the present invention to form a bioink.

Embodiment 3

[0052] Example 3 Preparation of bioprinting ink

[0053] (1) The raw materials used in the bio-ink in this example consist of the following components by mass percentage: 8.0% gelatin, 0.3% bacterial cellulose, 0.8% growth factor, 16.7% transglutaminase, and 74.2% sterile PBS solution.

[0054] (2) The preparation method is the same as in Example 1 of the present invention to form a bioprinting ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com