A kind of synthetic method of hydroxybenzylamine

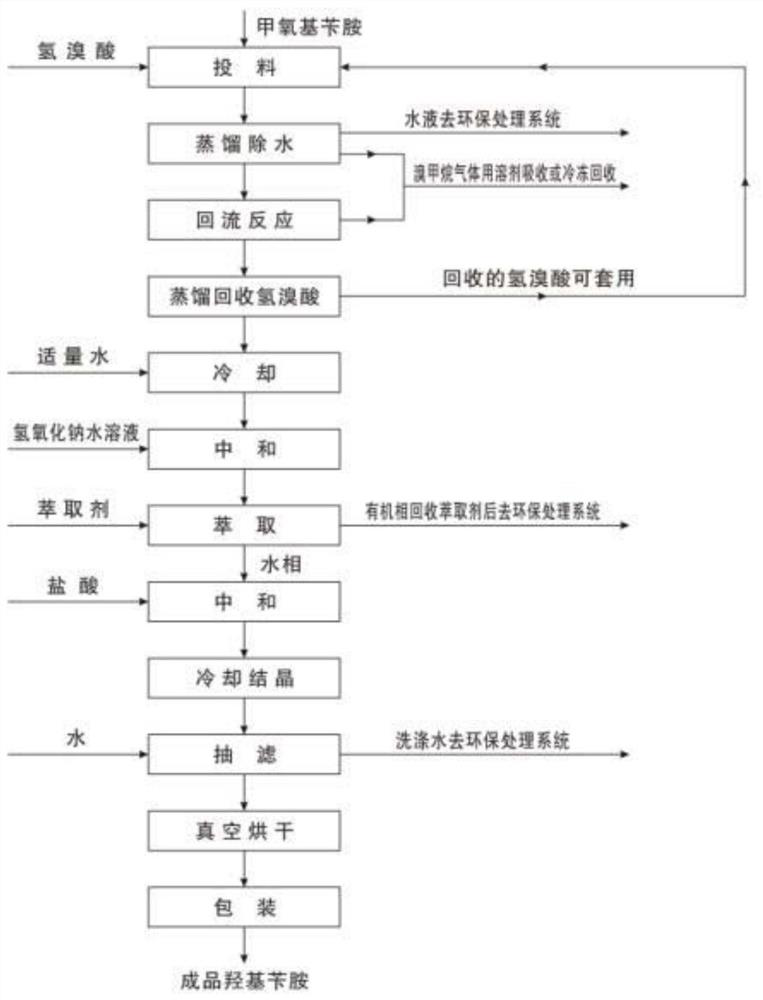

A synthesis method and technology of hydroxybenzylamine, applied in the field of synthesis of hydroxybenzylamine, can solve problems such as unsatisfactory reaction speed and conversion rate, difficult separation and purification of products, increase in the amount of sodium hydroxide, etc., and achieve environmental protection , The effect of short reaction time and low consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

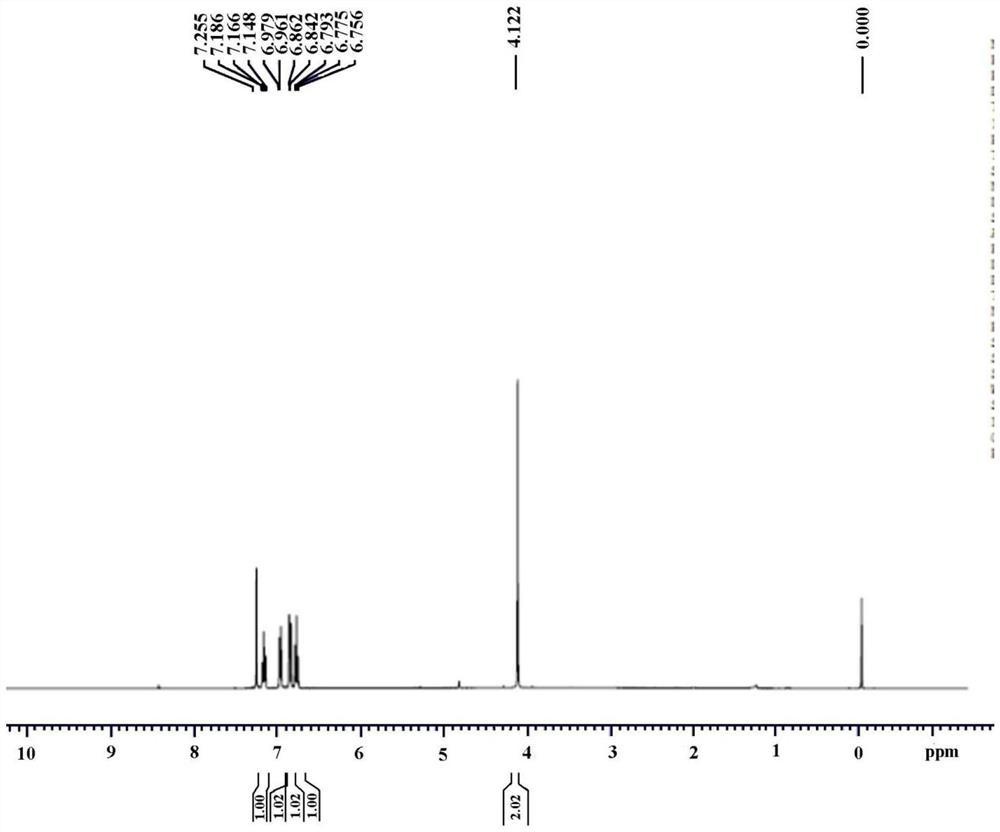

[0040] Embodiment 1: the synthesis of 2-hydroxybenzylamine

[0041] Drop into 252.8 grams (1.5 mole) 48% hydrobromic acid in 0.5L reactor with thermometer, dropping funnel, adjustable power heating mantle, stirrer and distillation unit, utilize dropping funnel under the stirring of stirrer to slowly Add 68.6 grams (0.5 moles) of 2-methoxybenzylamine dropwise, after the dropwise addition, heat up and distill to remove excess water until the top temperature of the distillation reaches more than 120°C (at this time, the temperature in the reactor reaches more than 126°C), and then Reduce the heating rate, make it into a reflux state or distill it out at a very slow rate, keep the temperature in the reactor above 126°C, absorb the generated gas with a solvent or recover it by freezing to protect the environment, until no further gas is observed When the gas is generated, increase the heating rate again, continue distillation, recover excess hydrobromic acid, until the temperature ...

Embodiment 2

[0043] Embodiment 2: the synthesis of 3-hydroxybenzylamine

[0044] Put 708.0 grams (3.5 moles) of 40% hydrobromic acid into a 1L reactor with a thermometer, dropping funnel, adjustable power heating mantle, stirrer and distillation device, and slowly drop it using the dropping funnel under the stirring of the stirrer. Add 137.2 grams (1.0 moles) of 3-methoxybenzylamine, after the dropwise addition, heat up and distill to remove excess water until the distillation temperature reaches above 120°C (at this time, the temperature in the reactor reaches above 126°C), and the heating rate is reduced , make it into a reflux state or distill it off at a very slow rate, keep the temperature in the reactor above 126°C, absorb the generated gas with a solvent or recover it by freezing to protect the environment, until no more gas is observed , increase the heating rate again, continue distillation, reclaim excess hydrobromic acid, stop when the temperature in the reactor reaches more tha...

Embodiment 3

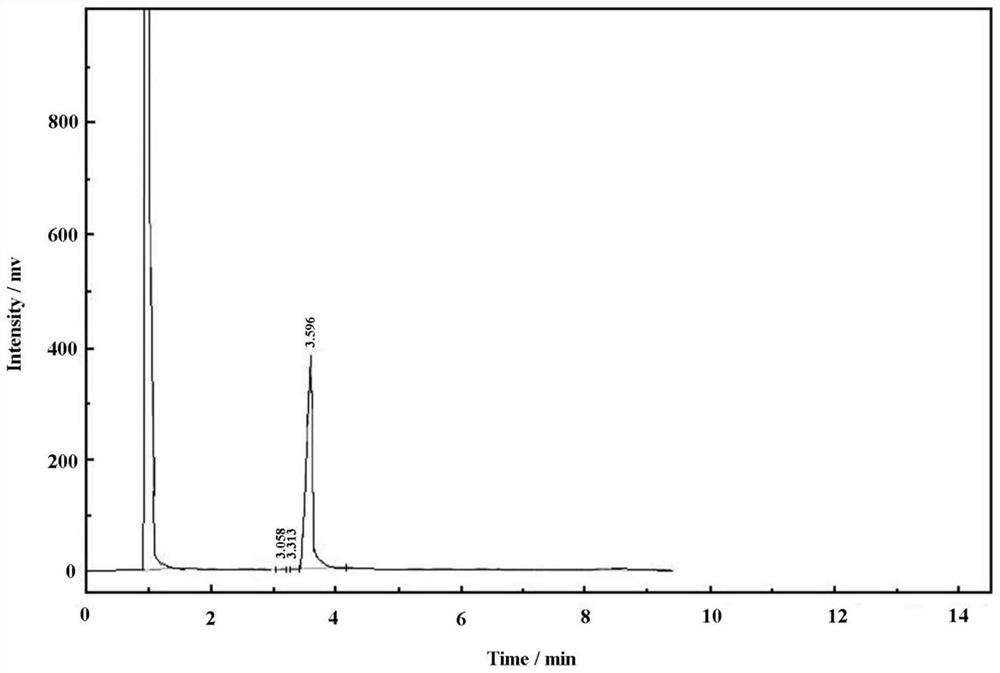

[0046] Embodiment 3: the synthesis of 4-hydroxybenzylamine

[0047] Put 970.9 grams (3.0 moles) of 25% hydrobromic acid into a 1L reactor with a thermometer, dropping funnel, adjustable power heating mantle, stirrer and distillation device, and slowly drop it using the dropping funnel under the stirring of the stirrer. Add 103.7 grams (0.7558 moles) of 4-methoxybenzylamine, after the dropwise addition, heat up and distill to remove excess water until the distillation temperature reaches more than 120°C (at this time, the temperature in the reactor reaches more than 126°C), reduce the heating rate , make it into a reflux state or distill it off at a very slow rate, keep the temperature in the reactor above 126°C, absorb the generated gas with a solvent or recover it by freezing to protect the environment, until no more gas is observed , increase the heating rate again, continue distillation, reclaim excess hydrobromic acid, stop when the temperature in the reactor reaches above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com