Method for preparing 1-ferrocenyl-3-aryl-3-(ethyl dicarboxylate methine)-acetone

An ethyl dicarboxylate-based methine and ferrocene-based technology, applied in the field of chemical synthesis, can solve the problems of low product yield, accelerated reaction process, inconvenient product purification, etc., and achieves the effect of reducing costs and overcoming non-recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11- 2

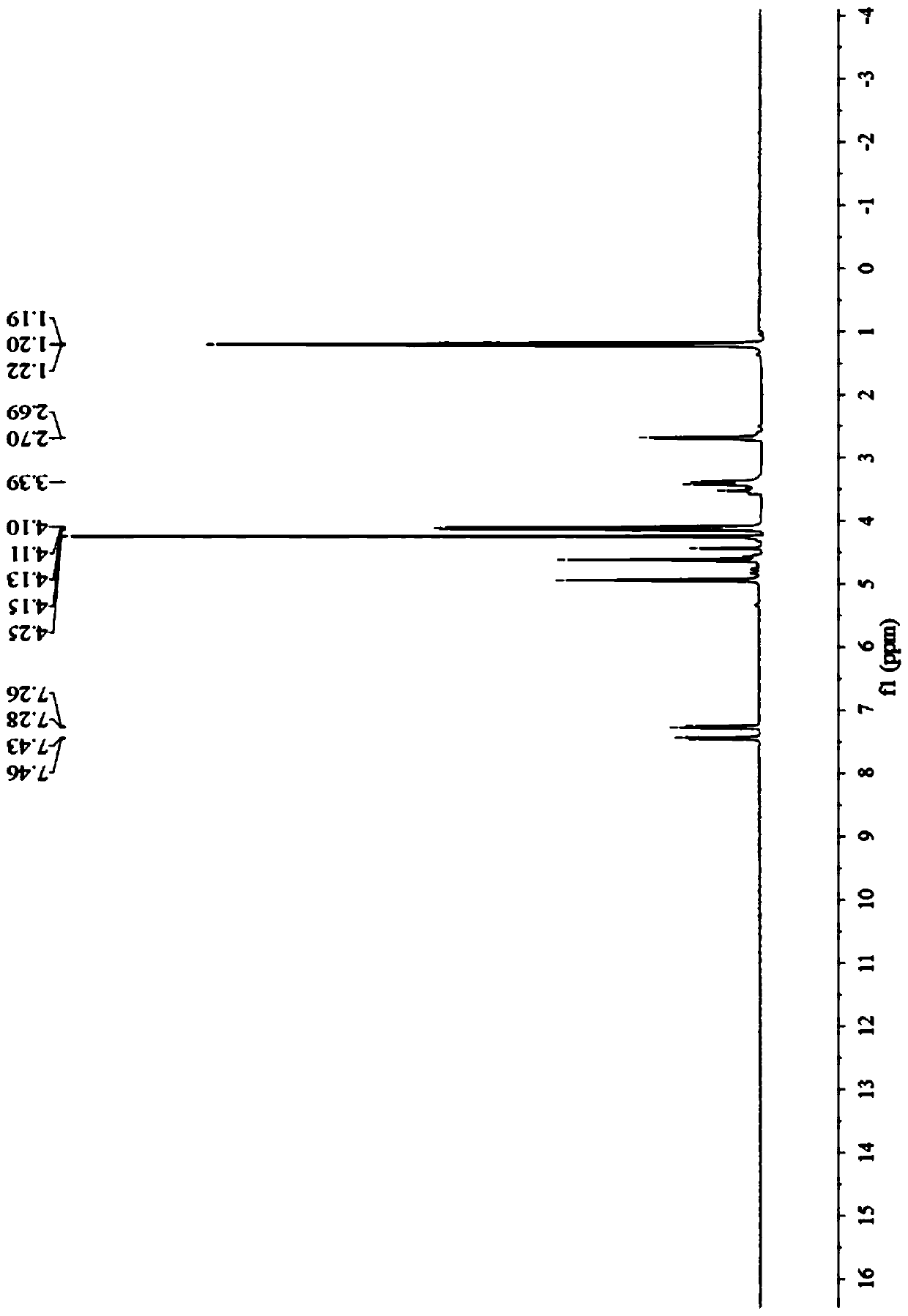

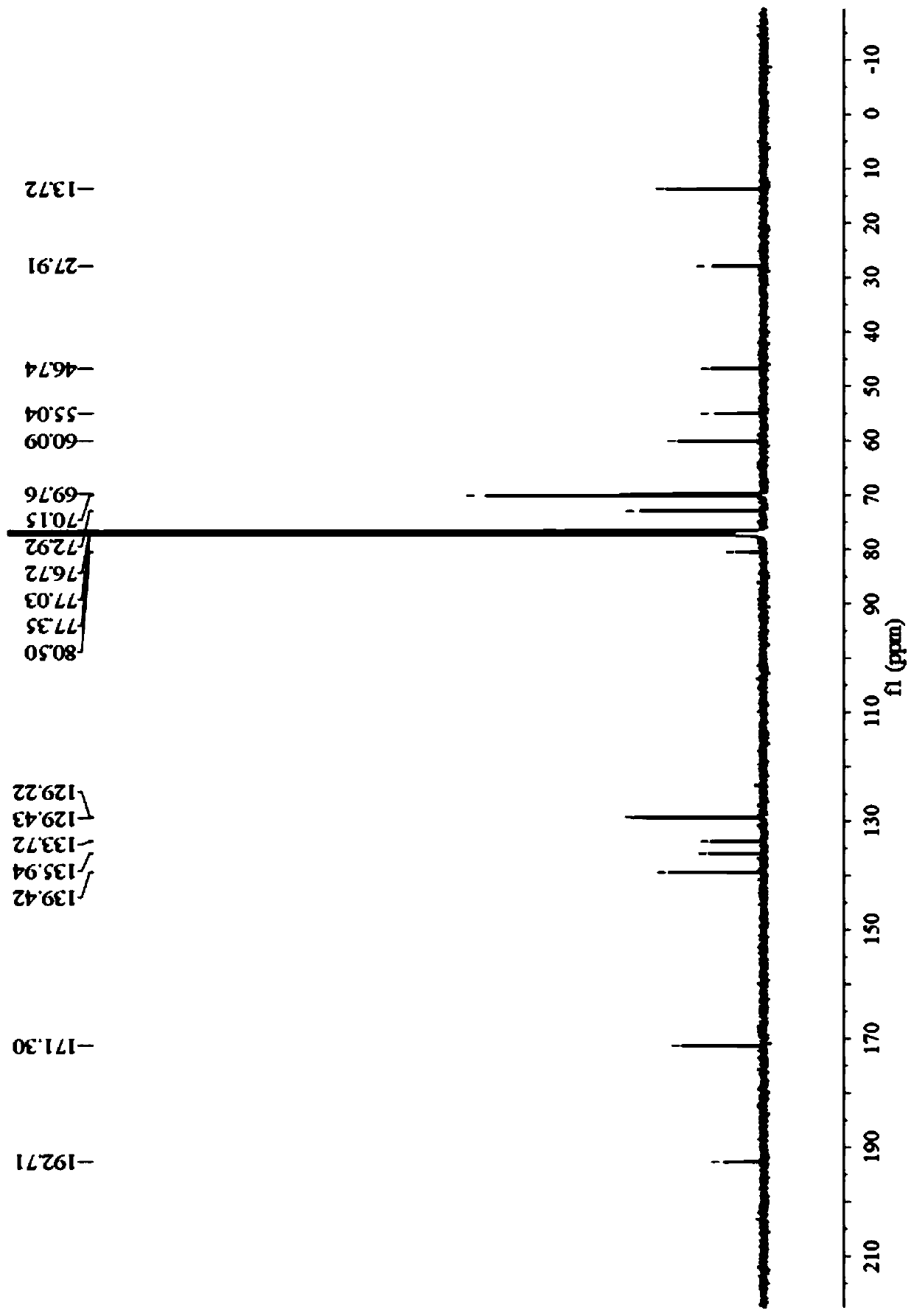

[0044] Preparation of Example 11-ferrocenyl-3-phenyl-3-(ethyl dicarboxylate methine)-acetone:

[0045]

[0046] In the first step, add 1mol choline chloride and 2mol urea to the reaction vessel, stir at 80°C until completely dissolved to obtain a deep eutectic solvent;

[0047] In the second step, after the reaction system is cooled to room temperature, add 0.01mol1-ferrocenyl-3-aryl-propenone and 0.012mol diethyl malonate, slowly heat up, reflux reaction, TLC monitoring until the end of the reaction ( 25min);

[0048] In the third step, the reaction solution was cooled to room temperature, and a solid was precipitated, filtered with suction, and the filter cake was washed with a small amount of water to obtain 1-ferrocenyl-3-phenyl-3-(ethyl dicarboxylate methine)-acetone . The yield was 83.4%, m.p.: 110-112°C; the filtrate was recovered to obtain a deep eutectic solvent. The yield of the deep eutectic solvent was 83.1% for the first time, 82.8% for the second time, 82.3...

Embodiment 21- 2

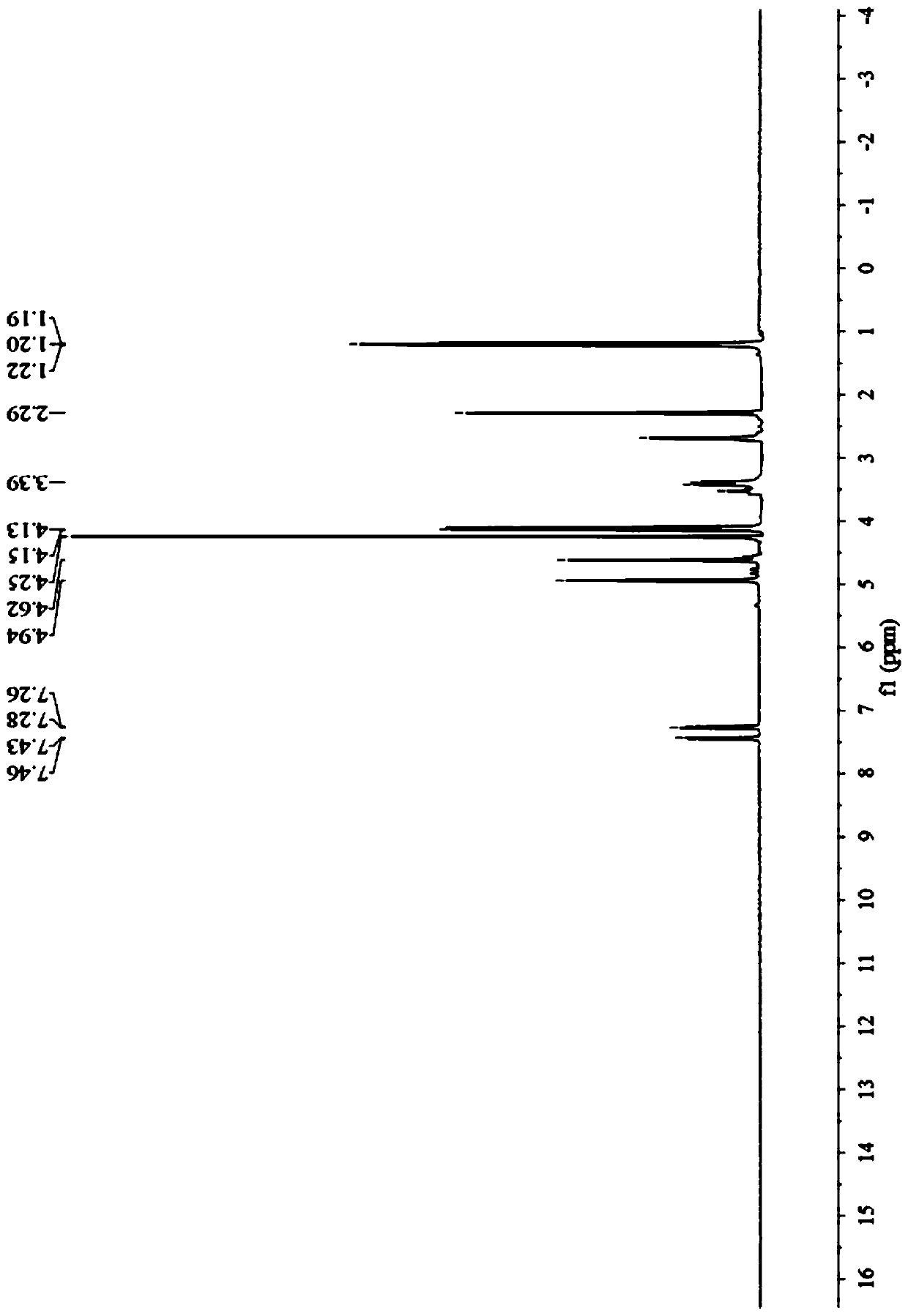

[0053] Example 21- Preparation of ferrocenyl-3-(p-bromophenyl)-3-(ethyl dicarboxylate methine)-acetone:

[0054]

[0055] In the first step, add 1mol choline chloride and 2mol urea to the reaction vessel, stir at 80°C until completely dissolved to obtain a deep eutectic solvent;

[0056] In the second step, after cooling the reaction system to room temperature, add 0.01mol 1-ferrocenyl-3-(p-bromophenyl)-propenone and 0.012mol diethyl malonate, slowly heat up, reflux reaction, TLC monitoring To the end of reaction (30min);

[0057] In the third step, the reaction solution was cooled to room temperature, and a solid was precipitated, filtered with suction, and the filter cake was washed with a small amount of water to obtain 1-ferrocenyl-3-(p-bromophenyl)-3-(ethyl dicarboxylate methine base) - acetone. The yield was 86.6%, m.p.: 116-117°C; the filtrate was recovered to obtain a deep eutectic solvent. The yield of the deep eutectic solvent was 86.4% for the first time, 86% fo...

Embodiment 31- 2

[0062] Example 31- Preparation of ferrocenyl-3-(p-methoxyphenyl)-3-(dicarboxyethyl methine)-acetone:

[0063]

[0064] In the first step, add 1mol choline chloride and 2mol urea to the reaction vessel, stir at 80°C until completely dissolved to obtain a deep eutectic solvent;

[0065] In the second step, after cooling the reaction system to room temperature, add 0.01mol 1-ferrocenyl-3-(p-methoxyphenyl)-propenone and 0.012mol diethyl malonate, slowly heat up, and reflux reaction, TLC monitors to the end of reaction (30min);

[0066] In the third step, the reaction solution is cooled to room temperature, and solids are precipitated, filtered with suction, and the filter cake is washed with a small amount of water to obtain 1-ferrocenyl-3-(p-methoxyphenyl)-3-(ethyl dicarboxylate) methine)-acetone. The yield is 85.8%, m.p.: 135-136°C; the filtrate is recovered to obtain a deep eutectic solvent. The yield of the deep eutectic solvent was 85.4% for the first time, 85.2% for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com