Sawtooth shuttle-shaped fan inner component heat exchanger device and heat exchange system

A technology of internal components and heat exchangers, applied in indirect heat exchangers, heat transfer modification, heat exchange equipment, etc., can solve the problems of poor heat transfer effect of heat exchangers, large pressure drop of heat exchangers, etc. Small pressure drop, small increase in pressure drop, and the effect of thinning thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

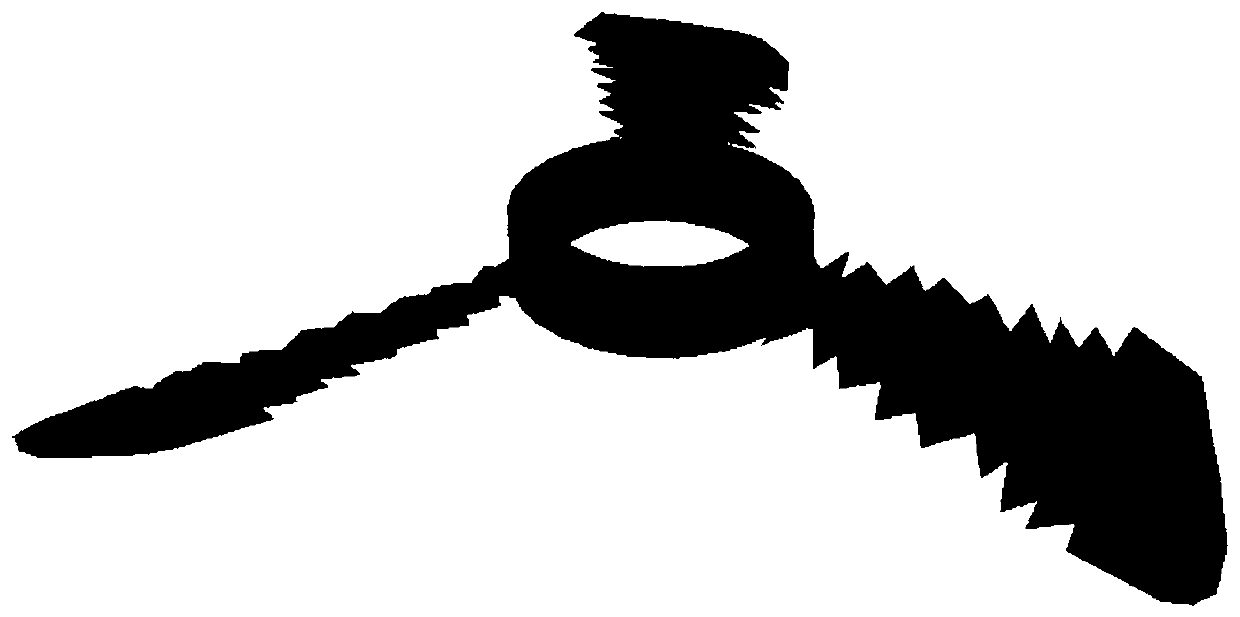

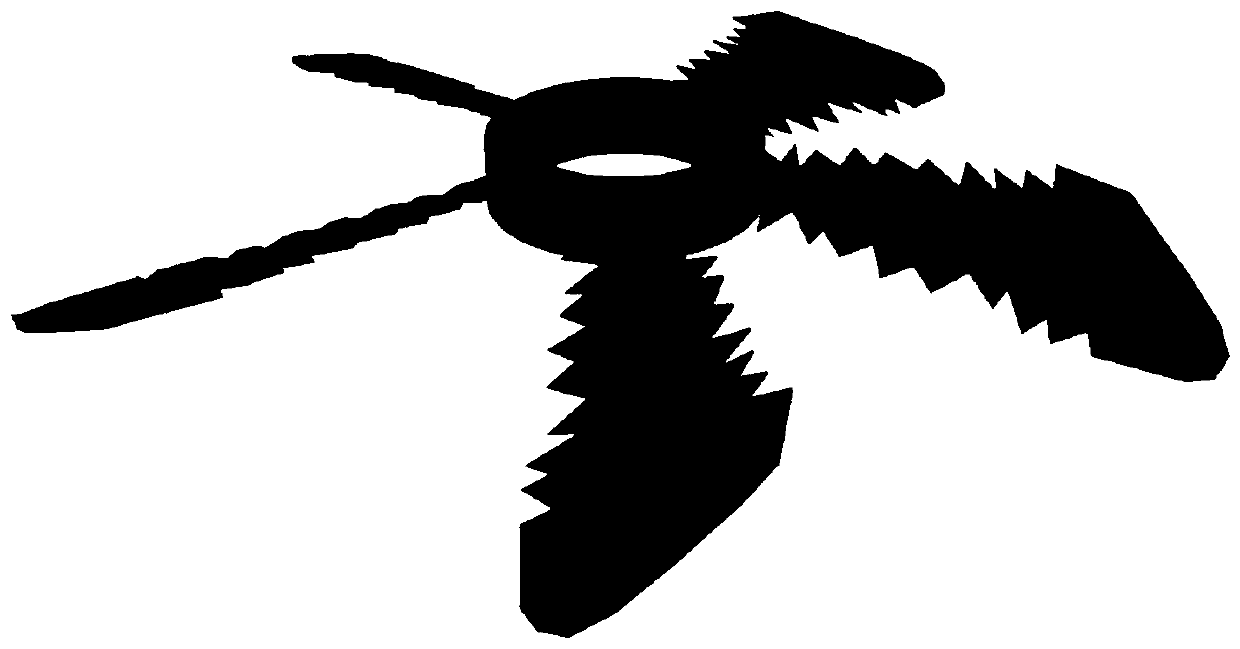

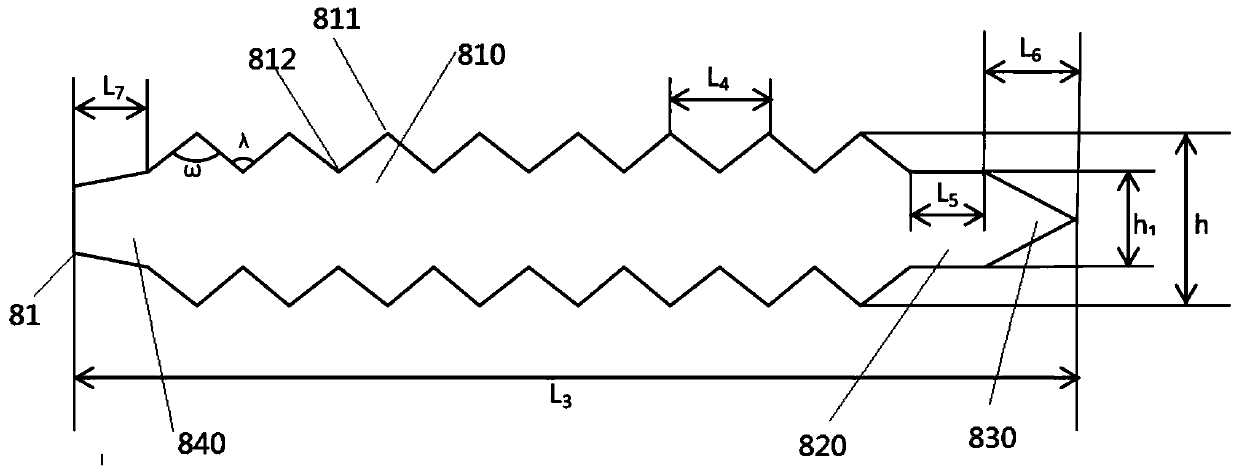

[0049] see Figure 1(a) to Figure 3 As shown, the present invention provides a sawtooth shuttle-shaped fan inner member heat exchanger device, including: a pipe box 1 , a sawtooth shuttle fan inner member 8 , a fixed shaft 3 , a lower support plate 2 and an upper support plate 4 .

[0050] The bottom of the pipe box 1 is provided with a cold fluid inlet 9, and the top is provided with a cold fluid outlet 5 and a cold fluid outlet thermometer 15; inside the pipe box 1, a lower support plate 2 is installed near the cold fluid inlet 9, near the cold fluid outlet The upper support plate 4 is installed at 5 places; the lower support plate 2 and the upper support plate 4 are provided with some air vents. The fixed shafts 3 of several sawtooth shuttle-shaped fan inner components are installed between the lower support plate 2 and the upper support plate 4; bearings 7 are installed on the fixed shaft 3, and the outer ends of the bearings 7 are equipped with sawtooth shuttle-shaped fan...

Embodiment 1

[0072] The internal component of the three-blade sawtooth shuttle fan is I, the internal component of the five-blade sawtooth shuttle fan is II, and the inclination angle of the blade is α. After CFD fluid mechanics software simulation, the vorticity of the two blades at different inclination angles is as follows: Figure 5 As shown, it can be seen from the figure that when the inclination angle reaches 18°, the maximum vorticity of the five-bladed sawtooth shuttle fan is relatively moderate, and when the inclination angle is 15° or 21°, the vorticity is relatively large. Therefore, when the inclination angle is 18°, the internal components of the five-blade sawtooth shuttle fan can improve the flow loss of gas, reduce the noise of air flow disturbance and the vibration of the fan. Therefore, the internal structure of the sawtooth shuttle-shaped fan with five blades and an inclination angle of 18° is better, and the present invention adopts this structure as the internal struct...

Embodiment 2

[0074] The cooling fluid in the tube is air, which is transported by the fan, enters the rotameter to measure the flow rate, and then enters the inner tube of the heat exchange tube with a flow rate of 50m3 / h. A string of sawtooth shuttle-shaped fan inner member strings are installed in the tube. The pipe gap is filled with steam, and the steam is produced by a steam generator. The internal components of the designed sawtooth shuttle fan can automatically rotate at high speed in the tube under the drive of air. A comparative experiment was carried out on the above devices.

[0075] Group I is fixed and static 15 groups of five-bladed sawtooth shuttle fan internal components;

[0076] Group II is self-rotating 15 sets of five-blade sawtooth shuttle fan internal components;

[0077] Two sets of heat exchangers were used to collect experimental data, and the results of the two sets of experiments Figure 6(a) and 6(b) Shown:

[0078] Depend on Figure 6(a) and 6(b) It can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com