A plasmonic terahertz waveguide generation device

A plasma and generation device technology, applied in the field of plasma, can solve the problems of inability to continuously adjust, structure cannot be reconfigured, slow response speed, etc., and achieve rapid turn-on and turn-off capabilities, good simultaneity, and fast dynamic response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

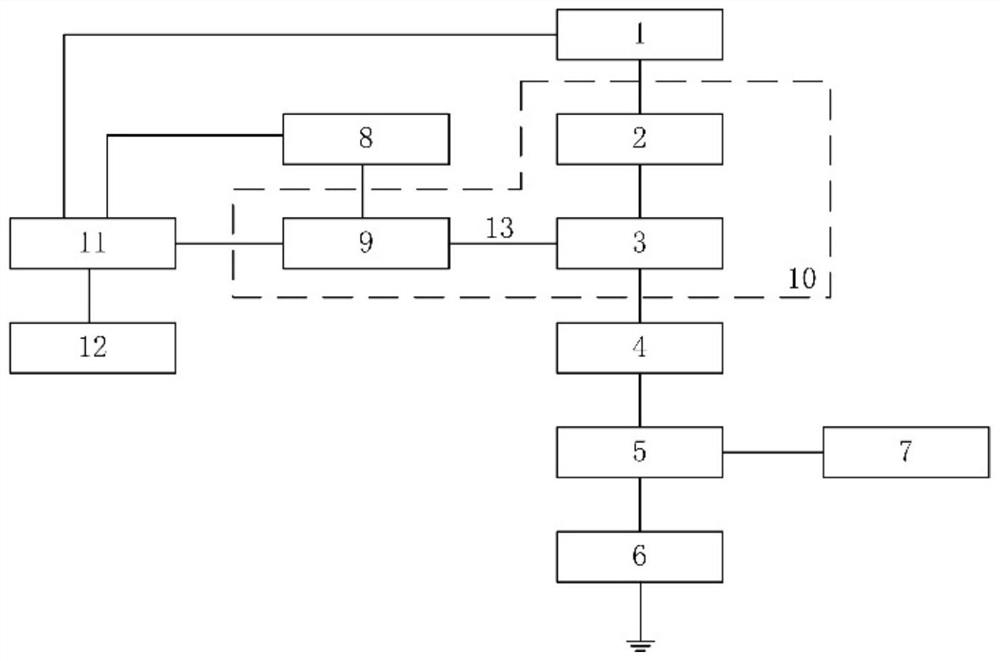

Method used

Image

Examples

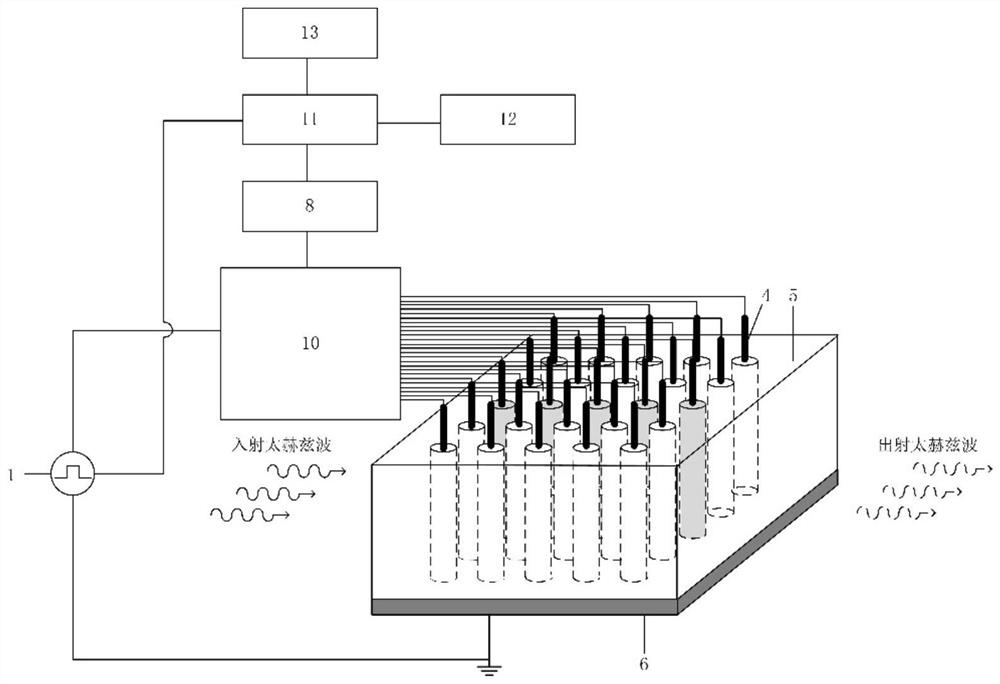

Embodiment 1

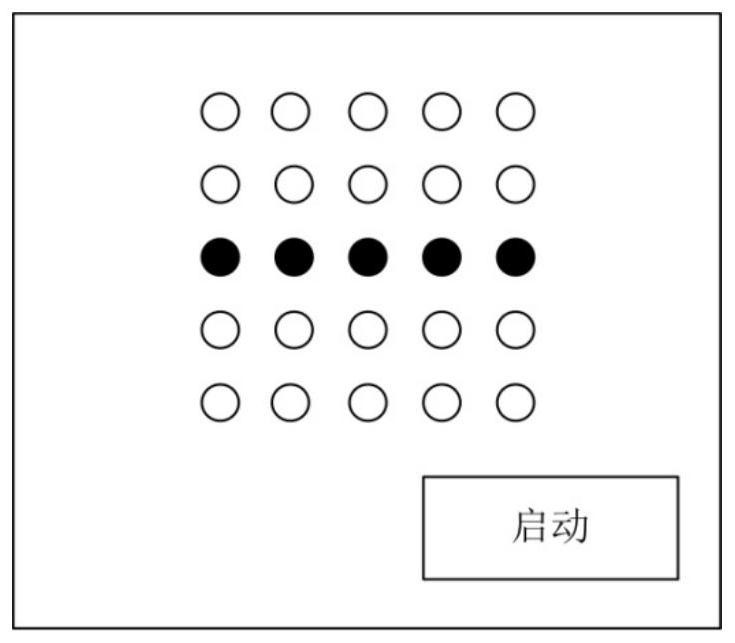

[0047] In this embodiment, the parameters of the high-voltage pulse power supply are voltage 0-20kV, frequency 1-30kHz, output pulse width 5μs, pulse rising edge less than 1μs. The number of resistors, high-voltage solid-state switches, drive modules, needle electrodes, and micro-vias is 25. The parameter of the resistance is 1kΩ / 1000W; the withstand voltage value of the high-voltage solid-state switch is 20kV, the maximum allowable effective current value is 20A, and the turn-on and turn-off time is 1μs; the material of the needle electrode is copper, and the needle body is inserted into the through hole of the dielectric board The inner part has an insulating coating on the outside. The insulating layer is made of epoxy resin with a thickness of 60 μm; the size of the dielectric board is 6 mm long x 6 mm wide x 5 mm thick, and there are 5 x 5 through holes in the center with a diameter of 300 μm. The pitch is 500 μm; the size of the ground electrode is 5 mm long×5 mm wide×1 ...

Embodiment 2

[0050] In this implementation, the parameters of the high-voltage pulse power supply are voltage 0-20kV, frequency 1-50kHz, output pulse width 1-50μs, and pulse rising edge less than 1μs. The number of resistors, high-voltage solid-state switches, drive modules, needle electrodes, and micro-vias is 70. The parameter of the resistor is 5kΩ / 500W; the withstand voltage of the high-voltage solid-state switch is 20kV, the maximum allowable effective current is 20A, and the turn-on and turn-off time is 1μs; the material of the needle electrode is copper, and the needle body is inserted into the through hole of the dielectric board The inner part has an insulating coating on the outside, and the insulating layer is made of epoxy resin with a thickness of 30 μm; the size of the dielectric board is 5 mm long x 6 mm wide x 5 mm thick, and there are 7 x 10 through holes in the center with a diameter of 100 μm. The pitch is 200 μm; the size of the ground electrode is 5mm long×5mm wide×1mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com