Fluorine-doped ammonium tungsten bronze photocatalyst with full-spectrum response, and preparation method thereof

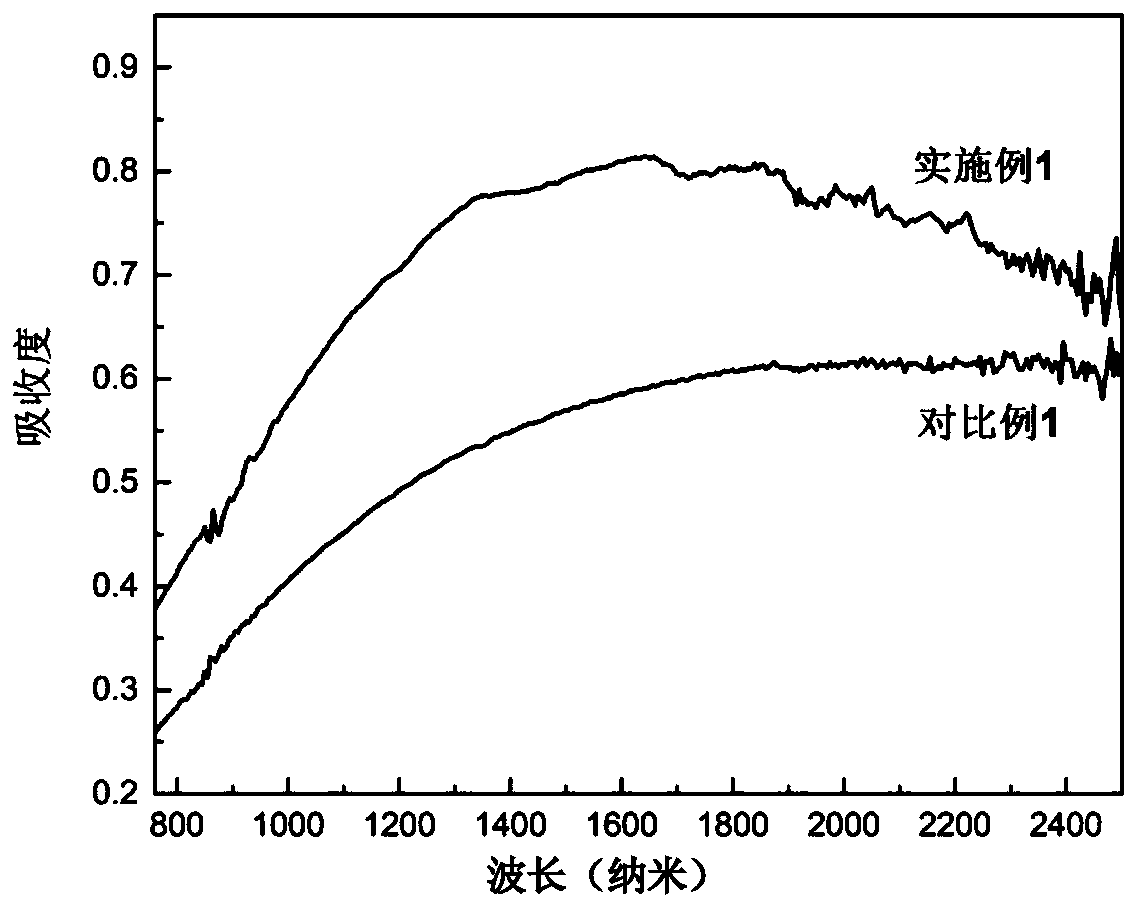

A photocatalyst and fluorine-doped technology, which is applied in the field of environmental purification and green energy utilization, can solve the problems of low near-infrared photocatalytic efficiency and narrow photocatalyst spectral utilization range, and achieve excellent ultraviolet-visible-near-infrared light Photocatalytic performance, the effect of improving photocatalytic performance and broadening the spectrum utilization range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a fluorine-doped ammonium tungsten bronze photocatalyst with full-spectrum response, comprising the following steps:

[0038] 1) Measure 60mL of n-propanol solution into a 100mL beaker, weigh 0.1166g of ammonium acetate and 0.6g of tungsten chloride into the n-propanol solution, and sonicate until dissolved to obtain a yellow solution;

[0039] 2) Then transfer the yellow solution to the lining of a 100mL p-polyphenylene reactor, and then add 0.75mL of hydrofluoric acid solution dropwise to the solution.

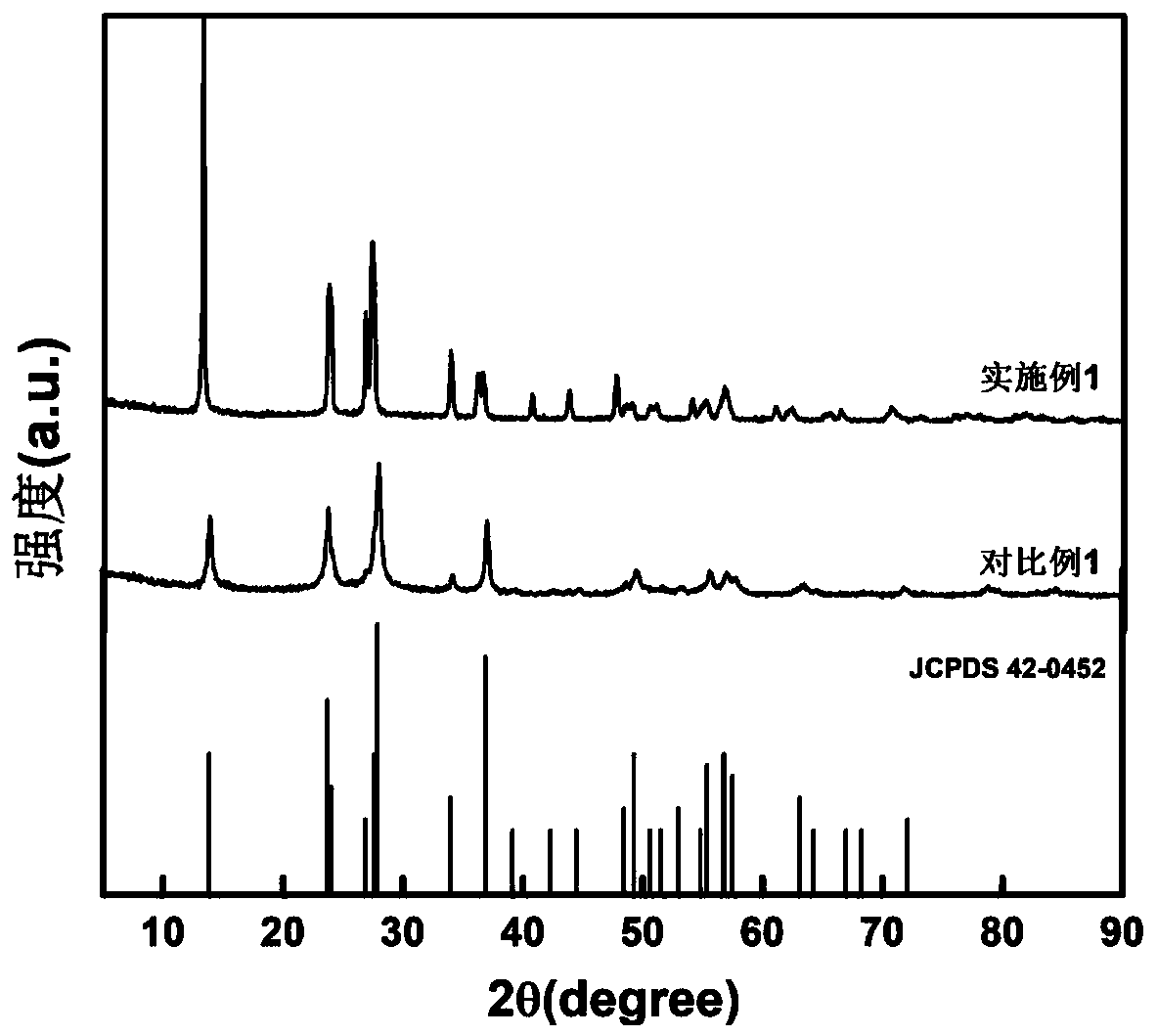

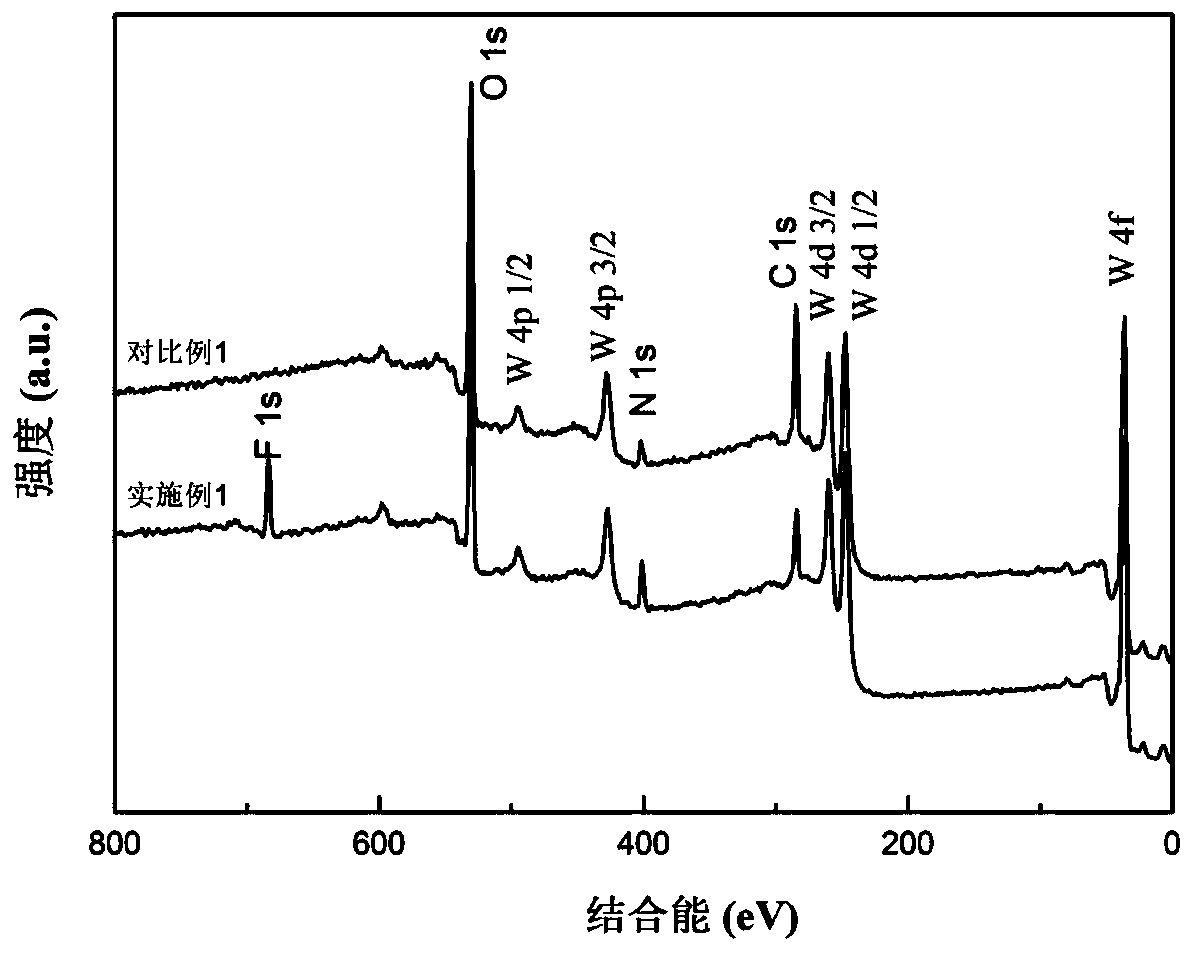

[0040] 3) Seal the reactor and place it in an oven for 24 hours at 190°C, cool naturally, wash the sample three times with deionized water and ethanol, centrifuge, and dry at 60°C to prepare fluorine-doped ammonium with full spectral response Tungsten bronze photocatalyst. The resulting product is (NH 4 ) 0.33 WO 2.26 f 0.74 .

Embodiment 2

[0045] A method for preparing a fluorine-doped ammonium tungsten bronze photocatalyst with full-spectrum response, comprising the following steps:

[0046] (1) Measure 60mL of n-propanol solution into a 100mL beaker, weigh 0.1166g of ammonium acetate and 0.6g of tungsten chloride into the n-propanol solution, sonicate until dissolved to obtain a yellow solution, and then dissolve the yellow solution Transfer to a 100mL p-polyphenylene reactor lining, and then add 0.25mL of hydrofluoric acid solution dropwise to the solution. Seal the reactor and place it in an oven for 24 hours at 190°C, cool naturally, wash the sample three times with deionized water and ethanol, centrifuge, and dry at 60°C to prepare a fluorine-doped ammonium tungsten bronze light with full spectral response. catalyst. The resulting product is (NH 4 ) 0.33 WO 2.46 f 0.54 .

Embodiment 3

[0048] A method for preparing a fluorine-doped ammonium tungsten bronze photocatalyst with full-spectrum response, comprising the following steps:

[0049] (1) Measure 60mL of n-propanol solution into a 100mL beaker, weigh 0.1166g of ammonium acetate and 0.6g of tungsten chloride into the n-propanol solution, sonicate until dissolved to obtain a yellow solution, and then dissolve the yellow solution Transfer to a 100mL p-polyphenylene reactor lining, and then add 1mL of hydrofluoric acid solution dropwise to the solution. Seal the reactor and place it in an oven for 24 hours at 190°C, cool naturally, wash the sample three times with deionized water and ethanol, centrifuge, and dry at 60°C to prepare a fluorine-doped ammonium tungsten bronze light with full spectral response. catalyst. The resulting product is (NH 4 ) 0.33 WO 2.2 f 0.8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com