Consistency screening method for high-rate lithium titanate unit cells

A single battery and screening method technology, applied in sorting and other directions, can solve the problems of unsuitable industrialization promotion and application, low screening efficiency, cumbersome calculation process, etc., to simplify the battery internal resistance test method, save equipment and electricity costs, The effect of an efficient screening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take a battery with a rated capacity of 25Ah, a positive electrode made of a ternary material, and a negative electrode made of lithium titanate as an example. In this embodiment, 11 batteries are selected to form a 24V 11-string battery pack.

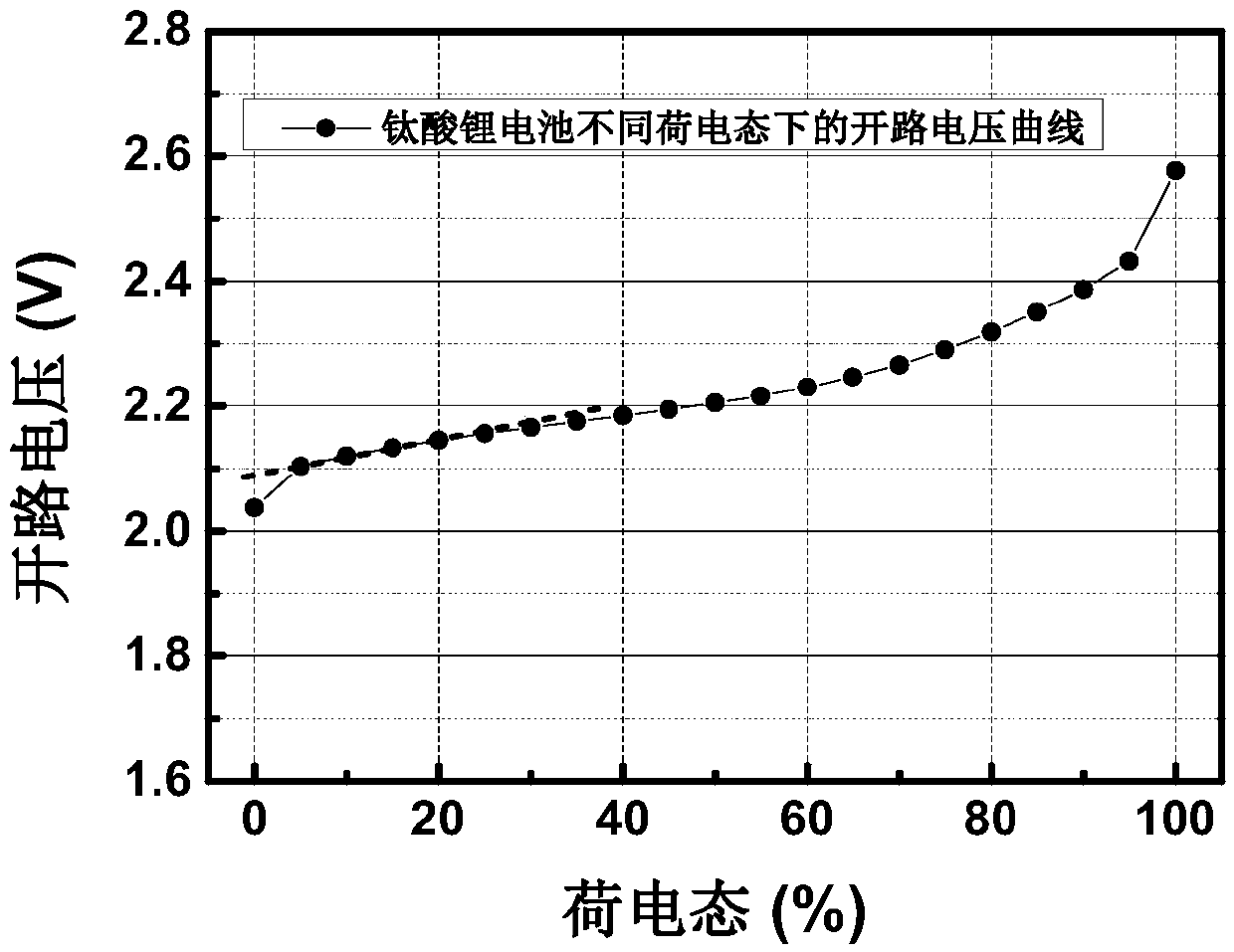

[0027] Step 1: Put the pre-charged battery on the test cabinet, charge it to 2.8V with 1C constant current and constant voltage, cut off the constant voltage charging current to 0.05C A, charge and discharge 3 times, record the discharge capacity D and constant voltage charging time CV -T; Charge the battery to 10% SOC (CC-CV charge to 2.365V, constant voltage cut-off current 0.05CA), measure the open circuit voltage OCV1 after 1 hour at room temperature;

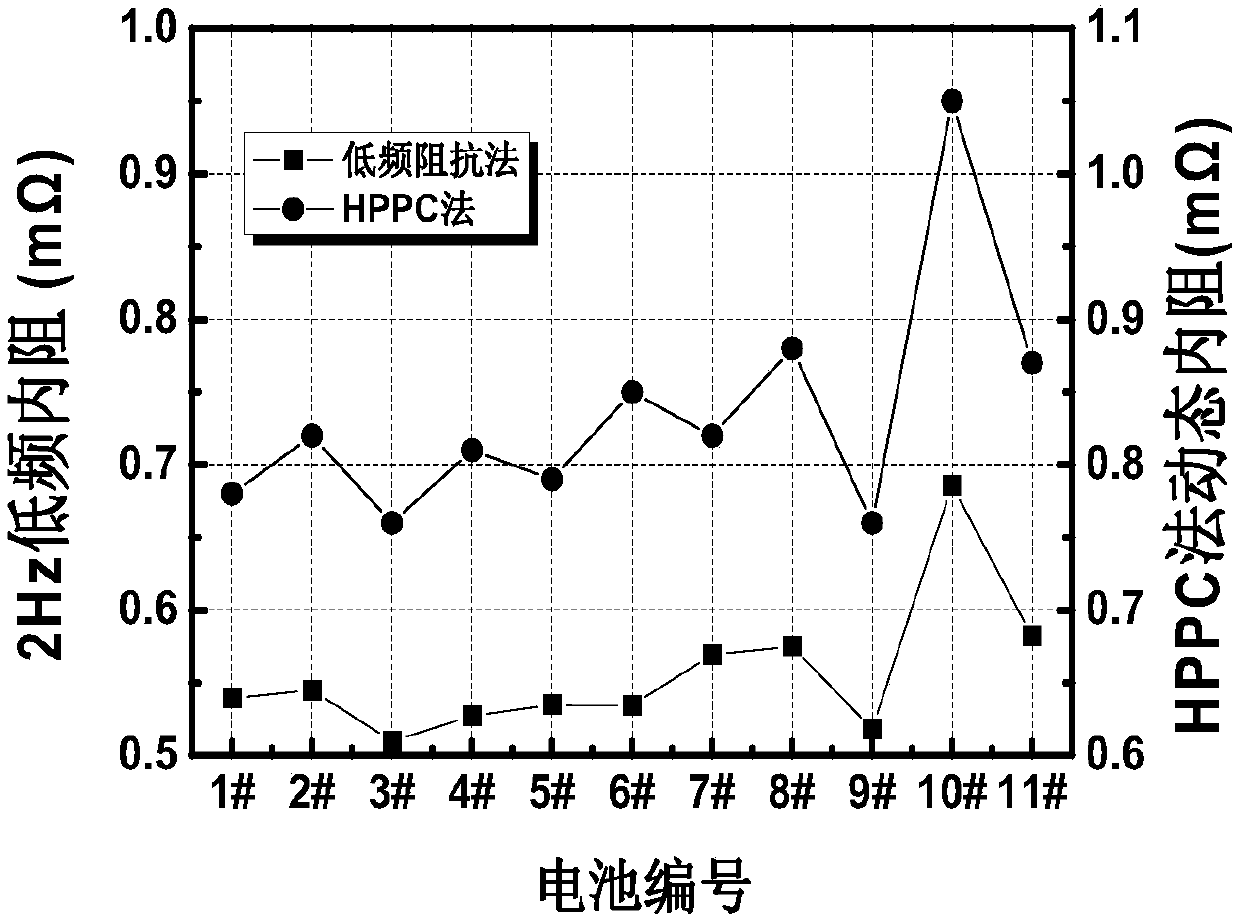

[0028] Step 2: Put the above battery in a constant temperature box at 55°C for 10 hours, take out the battery and cool it to room temperature, measure the open circuit voltage OCV2 of the battery, the static internal resistance Rh at a frequency of 1 kHz, and the single point...

Embodiment 2

[0031] Also taking a 25Ah ternary / lithium titanate battery as an example, 20 batteries are randomly tested in this embodiment.

[0032] The test process is the same as that of Example 1, except that the charging SOC in the first step in Example 1 is adjusted to 20% soc, and the battery is placed in a 55° C. incubator for 12 hours.

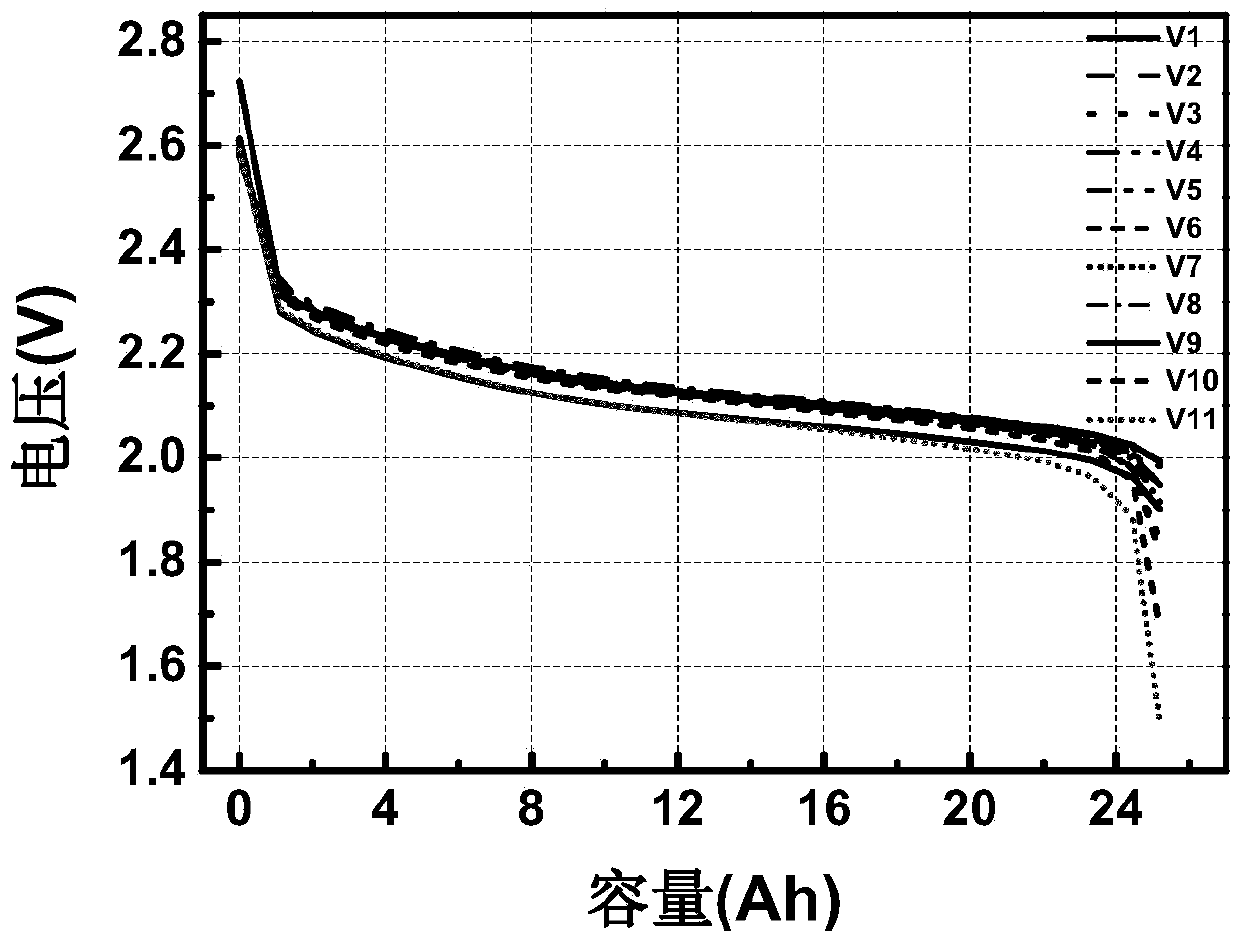

[0033] Table 3 is the detailed screening parameters of all 20 batteries in Example 2. Among them, although the battery capacity, constant voltage charging time, high-frequency AC internal resistance, OCV1 and OCV2 of 8#, 13# and 17# have little difference with other batteries, the low-frequency AC internal resistance exceeds the screening of 0-25% range, so these three batteries are judged to be unqualified batteries. Among the remaining qualified batteries, 11 batteries (respectively 1~3#, 9~12#, 14#, 18~20#) were randomly selected to form 11 strings of battery packs. Discharge performance under current, the results are shown in image 3 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com