Zirconia ceramic backboard and processing method thereof

A technology of zirconia ceramics and processing methods, applied in chemical instruments and methods, lamination, layered products, etc., can solve problems such as easy deformation of parts, uneven material density, cracking, etc. The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

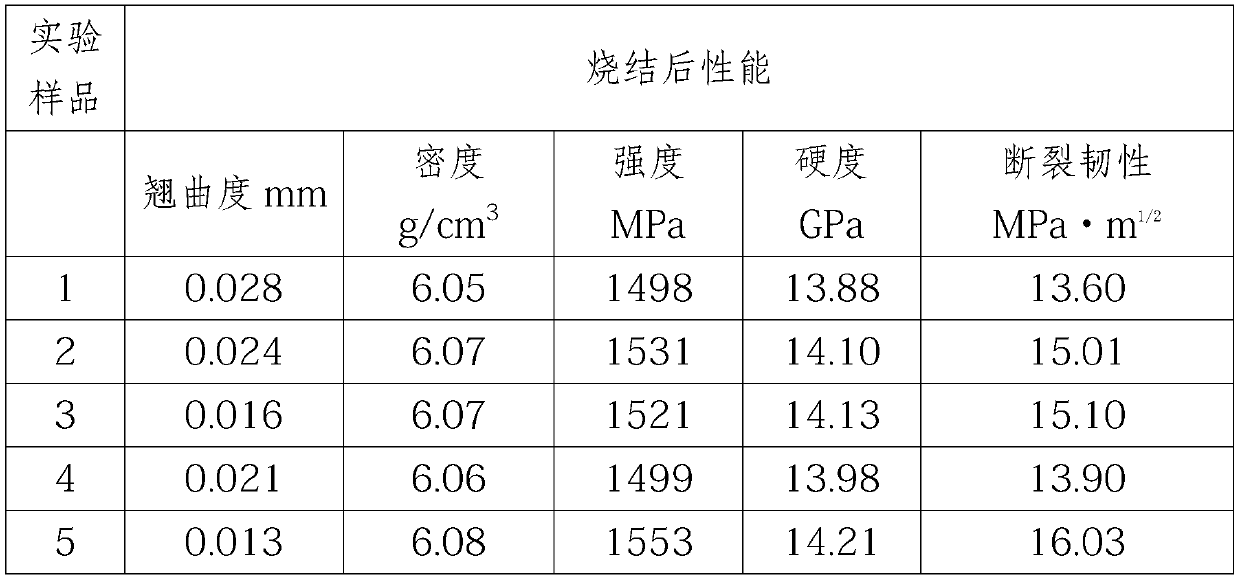

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the present invention will be described in detail below.

[0028]Due to the high hardness of ceramics, it is difficult to form and process ceramics. It can only be polished a little bit by diamond, and the forming efficiency is low. Only two pieces can be produced per day. This method is extremely inefficient, with serious material waste and low product qualification rate, which directly leads to the inability to reduce the manufacturing cost of the ceramic back cover. In this regard, in the prior art, as disclosed in the patent document with the publication number CN101844920A, a method for preparing colored zirconia ceramics belonging to the field of preparation of doped ceramic materials and the patent document with the publication number CN104003714B disclose the preparation of zirconia ceramics. A method for multi-color mobile phone parts, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Warpage | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com