Preparation method of natural mulberry silkworm/tussah silk fabric reinforced epoxy resin composite material

An epoxy resin and composite material technology, which is applied in the field of natural mulberry/tussah silk fiber fabric reinforced epoxy resin composite material and its preparation, can solve the problems such as the application of the impact resistance engineering structure of the silk fiber composite material without investigation, and achieve the improvement of Energy absorption capacity, simple preparation method, and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

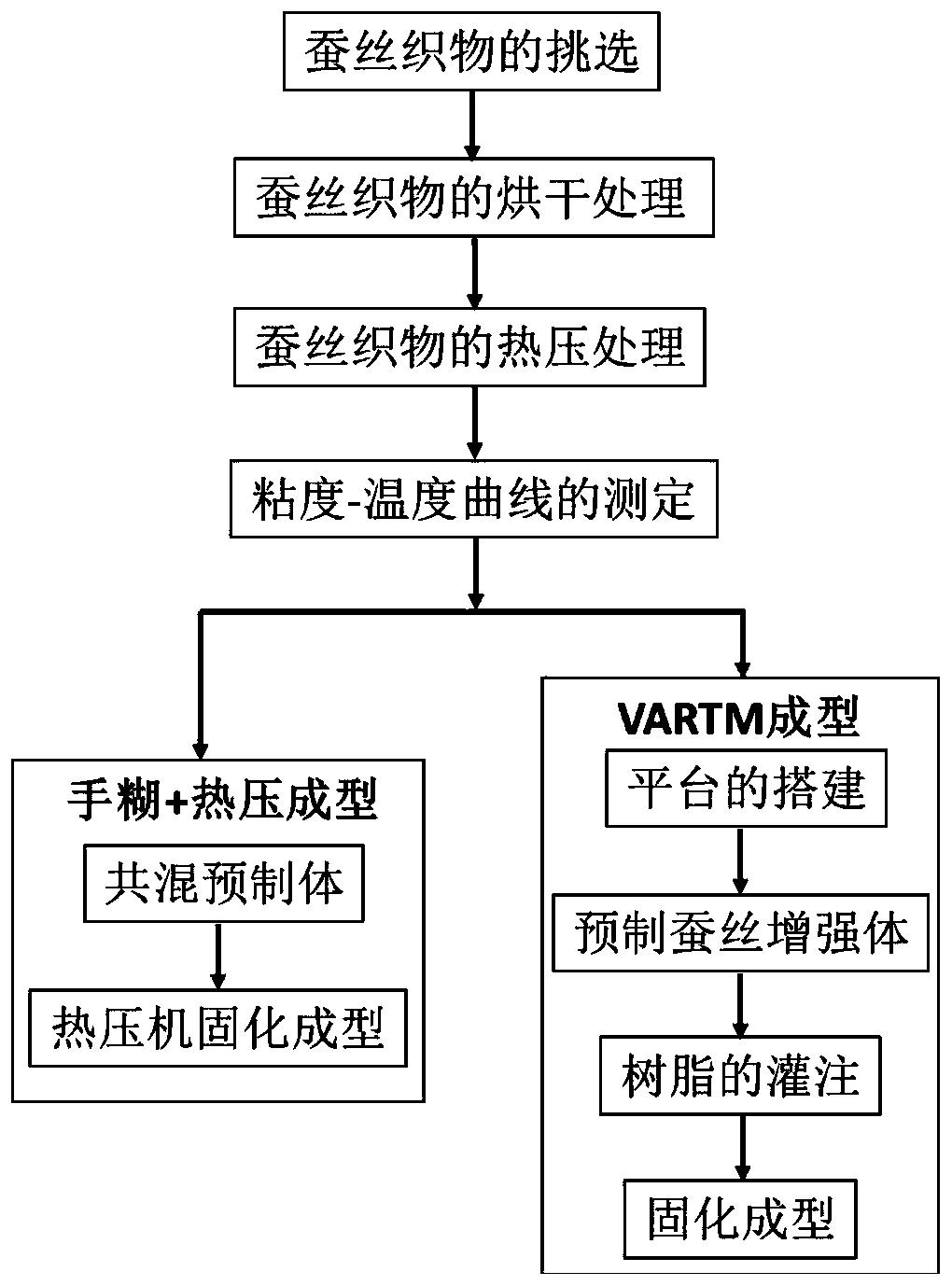

Method used

Image

Examples

Embodiment example 1

[0056] (1) Choose the mulberry silk fiber plain weave fabric produced by Huzhou Yongrui Textile Co., Ltd. (Zhejiang), with an area density of 90gm -2 , the number of fibers in the vertical and horizontal directions is the same, and each strand contains about 80 silk monofilament fibers. The mulberry silk fiber is degummed with sodium bicarbonate solution. Before blending with epoxy resin, the mulberry silk plain weave fabric is placed in an oven. The condition is 60°C for 5 hours, and then heat-pressed at 60°C to improve the flatness and compactness of the fabric;

[0057](2) Two different systems are used for the resin: a. Bisphenol A type E51 epoxy resin and curing agent BC12 (modified amine curing agent) produced by Dasen (Tianjin) Material Technology Co., Ltd., the weight ratio of the two It is 100:84, the curing temperature is 120 ℃, and the curing time is 2 hours; b. Araldite LY 1564 epoxy resin and Aradur 3486 curing agent produced by Huntsman Company, Araldite LY 1564 ...

Embodiment example 2

[0061] (1) Select the tussah silk fiber fabric produced by Ruifuxiang Silk Cloth Store (Beijing), with a surface density of 135g m -2 , the tussah silk plain weave cloth contains about 110 fibers per share in the longitudinal direction, and about 30 fibers in each share in the transverse direction, and the average cross-sectional area of each tussah silk fiber is 291um 2 . The tussah silk fiber is treated with alkali degumming and demineralization (the tussah silk fiber is different from mulberry silk, and there are a lot of mineral particles on the surface), before blending with epoxy resin, the mulberry silk plain weave fabric is placed in an oven at 60°C , 5 hours, and then heat-pressed at 60°C to improve the flatness and compactness of the fabric;

[0062] (2) The resin is bisphenol A type E51 epoxy resin and curing agent BC12 (modified amine curing agent) produced by Dasen (Tianjin) Material Technology Co., Ltd., the weight ratio of the two is 100:84, and the curing te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture energy | aaaaa | aaaaa |

| Average cross-sectional area | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com