Preparation method of tetravalent ion-doped toughened hafnium oxide-based high-temperature thermal protection material

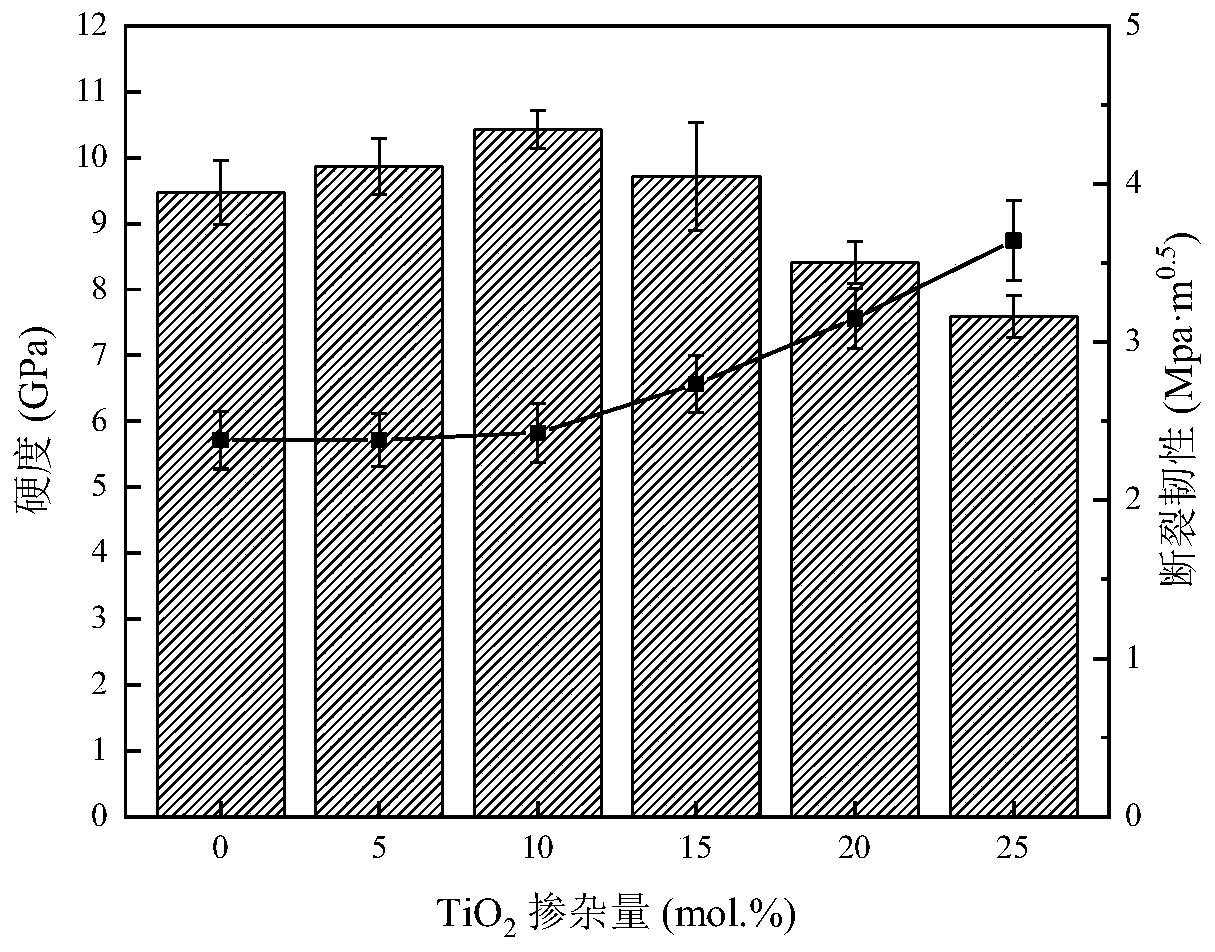

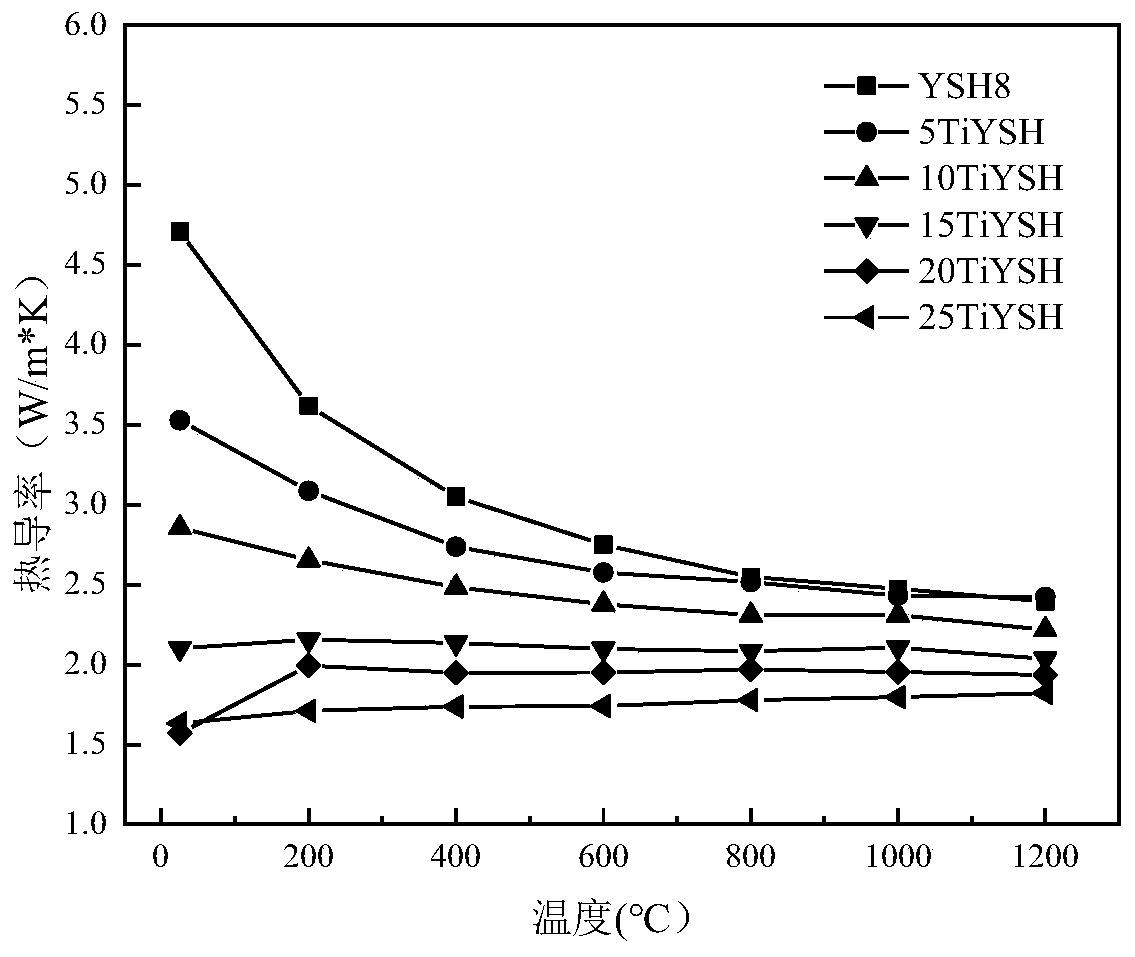

An ion doping and protective material technology, applied in the field of high temperature thermal protection, can solve the problems of YSZ sintering and material damage, and achieve the effect of good high temperature phase stability and good fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: (Hf 0.95 Ti 0.05 ) 0.92 Y 0.08 o 1.96 Preparation of Ceramic Blocks

[0021] (1) Weigh 0.3736g of titanium oxide powder of 99.9% purity, 18.7079g of hafnium oxide powder of 99.9% purity, 0.9185g of yttrium oxide powder of 99.9% purity and add in the ball mill jar, and add alcohol, zirconia grinding ball 100g altogether, Among them, 40g of 10mm grinding balls, 30g of 5mm grinding balls, and 30g of 1mm grinding balls, set the speed of the ball mill to 400r / min, and mill for 10 hours;

[0022] (2) Put the ball-milled slurry into a draft drying oven at 60°C for 10 hours, then grind the dried powder and sieve it with a 200-mesh sieve to obtain a powder with a particle size of less than 0.0750 mm;

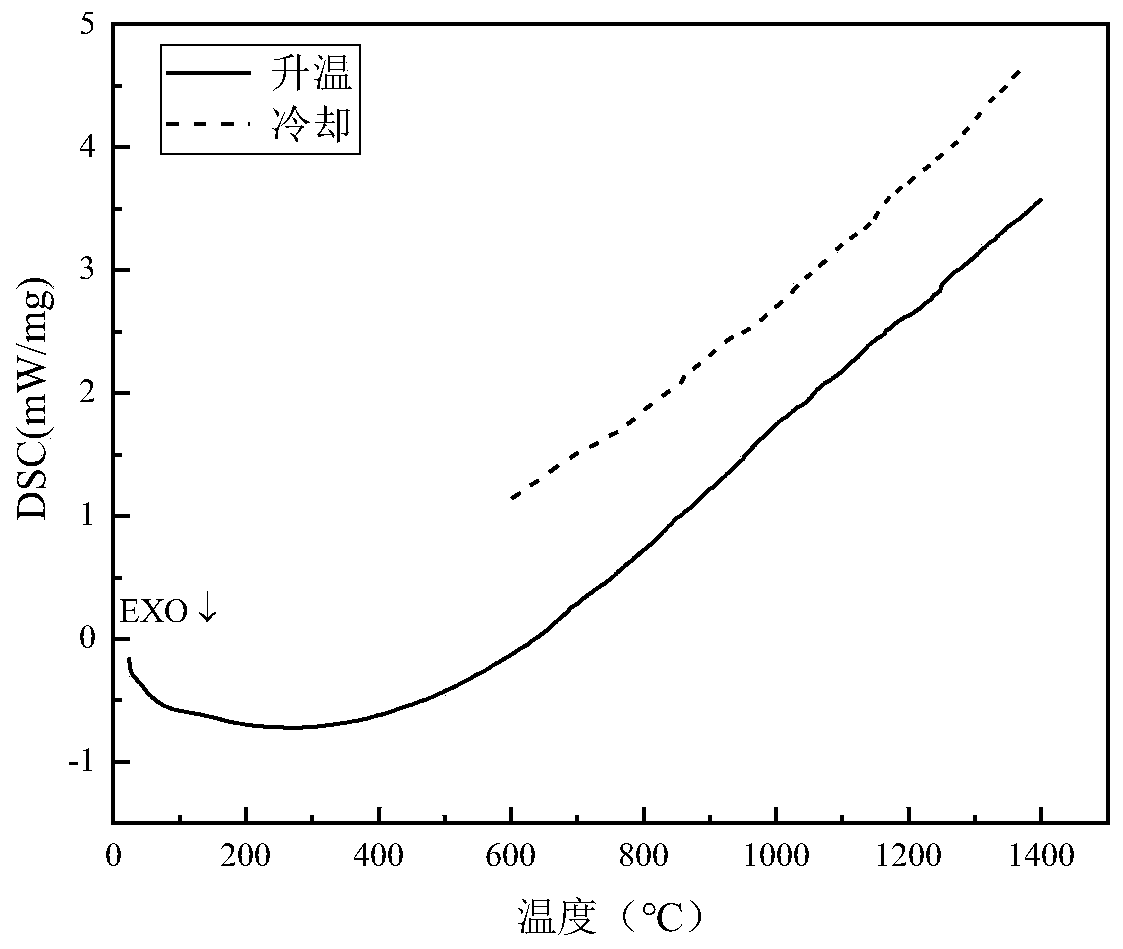

[0023] (3) Press the powder obtained in the previous step into a disc of φ15mm×2mm, press 20MPa, hold the pressure for 2 minutes, and finally put the obtained disc into a resistance furnace for pressureless sintering. The sintering parameter is from room tempera...

Embodiment 2

[0025] Embodiment 2: (Hf 0.9 Ti 0.1 ) 0.92 Y0.08 o 1.96 Preparation of Ceramic Blocks

[0026] (1) Weigh 0.7707g of titanium oxide powder of 99.9% purity, 18.2818g of hafnium oxide powder of 99.9% purity, 0.9475g of yttrium oxide powder of 99.9% purity and add it to the ball mill jar, and add 120ml of 75% alcohol, and zirconia grinding balls A total of 100g, including 40g of 10mm balls, 30g of 5mm balls, and 30g of 1mm balls, set the speed of the ball mill to 400r / min, and mill for 10 hours;

[0027] (2) Put the ball-milled slurry into a draft drying oven at 60°C for 10 hours, then grind the dried powder and sieve it with a 200-mesh sieve to obtain a powder with a particle size of less than 0.0750 mm;

[0028] (3) Press the powder obtained in the previous step into a disc of φ15mm×2mm, press 20MPa, hold the pressure for 2 minutes, and finally put the obtained disc into a resistance furnace for pressureless sintering. The sintering parameter is from room temperature to 1000...

Embodiment 3

[0030] Embodiment 3: (Hf 0.85 Ti 0.15 ) 0.92 Y 0.08 o 1.96 Preparation of Ceramic Blocks

[0031] (1) Weigh 1.1937g of titanium oxide powder of 99.9% purity, 17.8280g of hafnium oxide powder of 99.9% purity, 0.9783g of yttrium oxide powder of 99.9% purity and add it to the ball mill jar, and add 120ml of 75% alcohol, and zirconia grinding balls A total of 100g, including 40g of 10mm balls, 30g of 5mm balls, and 30g of 1mm balls, set the speed of the ball mill to 400r / min, and mill for 10 hours;

[0032] (2) Put the ball-milled slurry into a draft drying oven at 60°C for 10 hours, then grind the dried powder and sieve it with a 200-mesh sieve to obtain a powder with a particle size of less than 0.0750 mm;

[0033] (3) Press the powder obtained in the previous step into a disc of φ15mm×2mm, press 20MPa, hold the pressure for 2 minutes, and finally put the obtained disc into a resistance furnace for pressureless sintering. The sintering parameter is from room temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com