Ultra-light super-buoyancy carbon nano-tube material, preparation method and applications thereof

A technology of carbon nanotubes and carbon nanotube sponges, which is applied in the field of ultra-light and ultra-buoyant carbon nanotube materials, can solve the problems of low support force, low load-carrying ratio, and high material density, and is conducive to large-scale production. The preparation method is green and Good mechanical flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

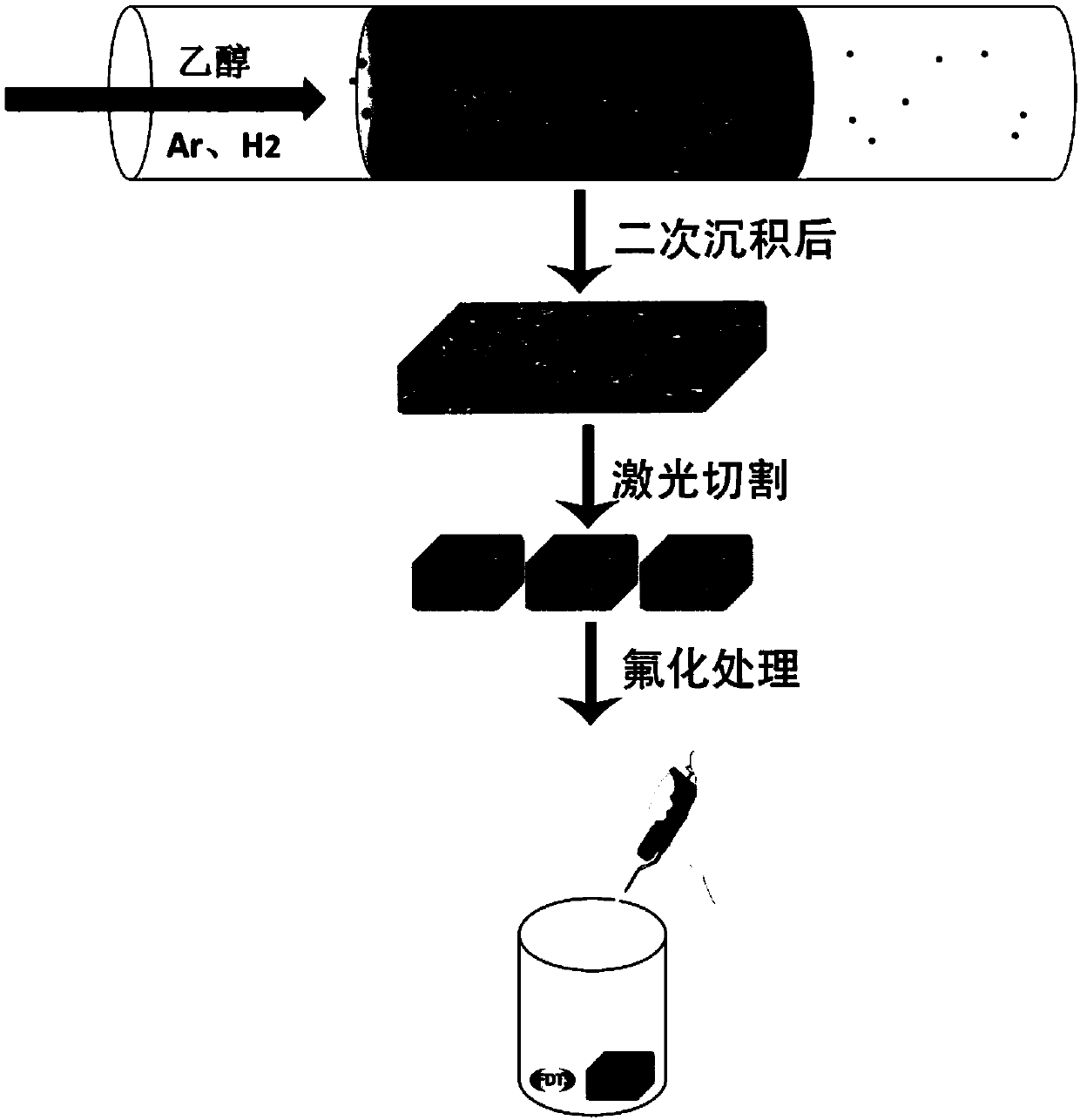

[0056] Another aspect of the embodiments of the present invention provides a method for preparing an ultra-light and ultra-buoyant carbon nanotube material comprising:

[0057] Provide a three-dimensional network structure formed by stacking multiple carbon nanotubes;

[0058] depositing carbon particles at least within said three-dimensional network by chemical vapor deposition, and

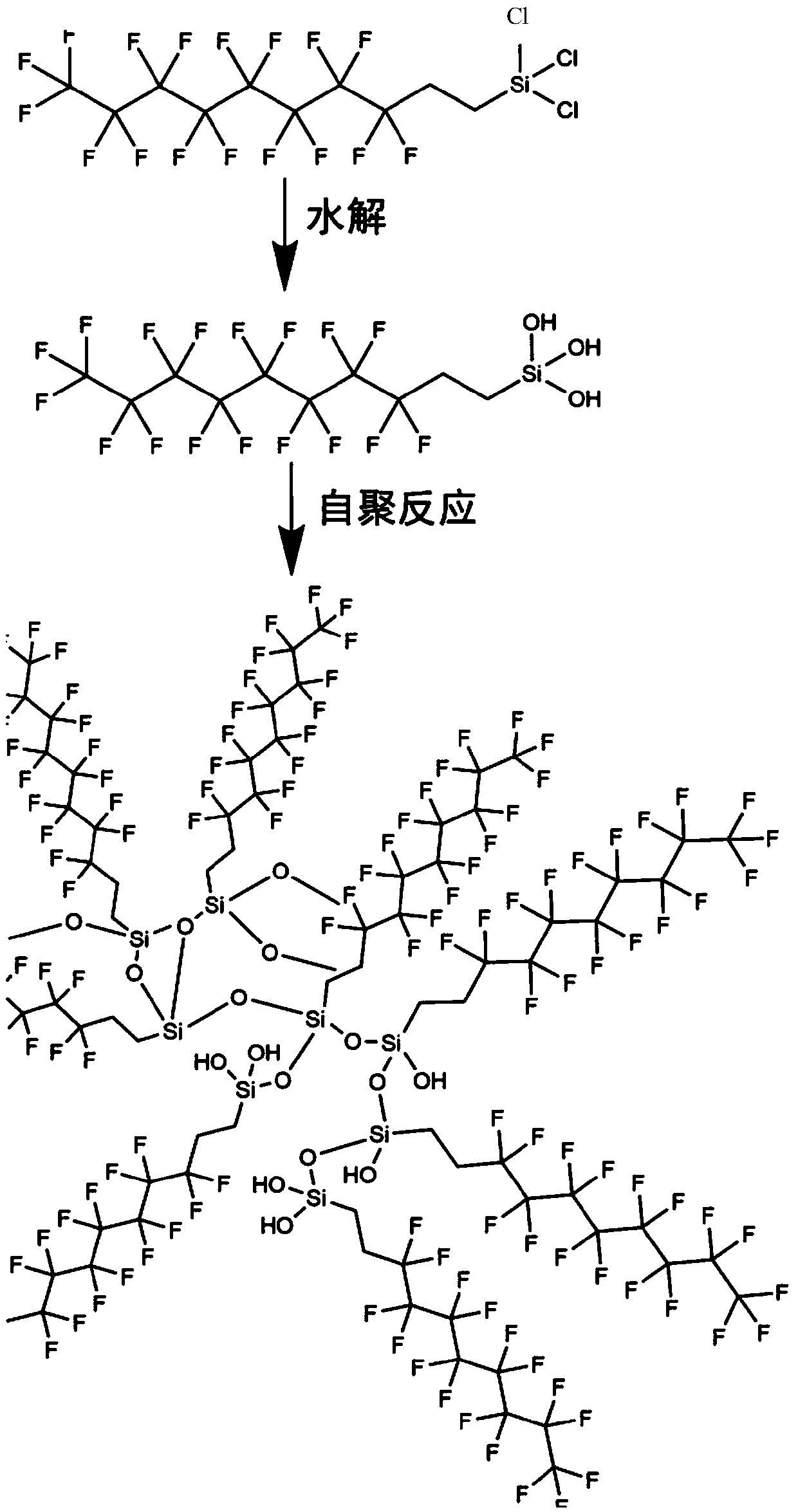

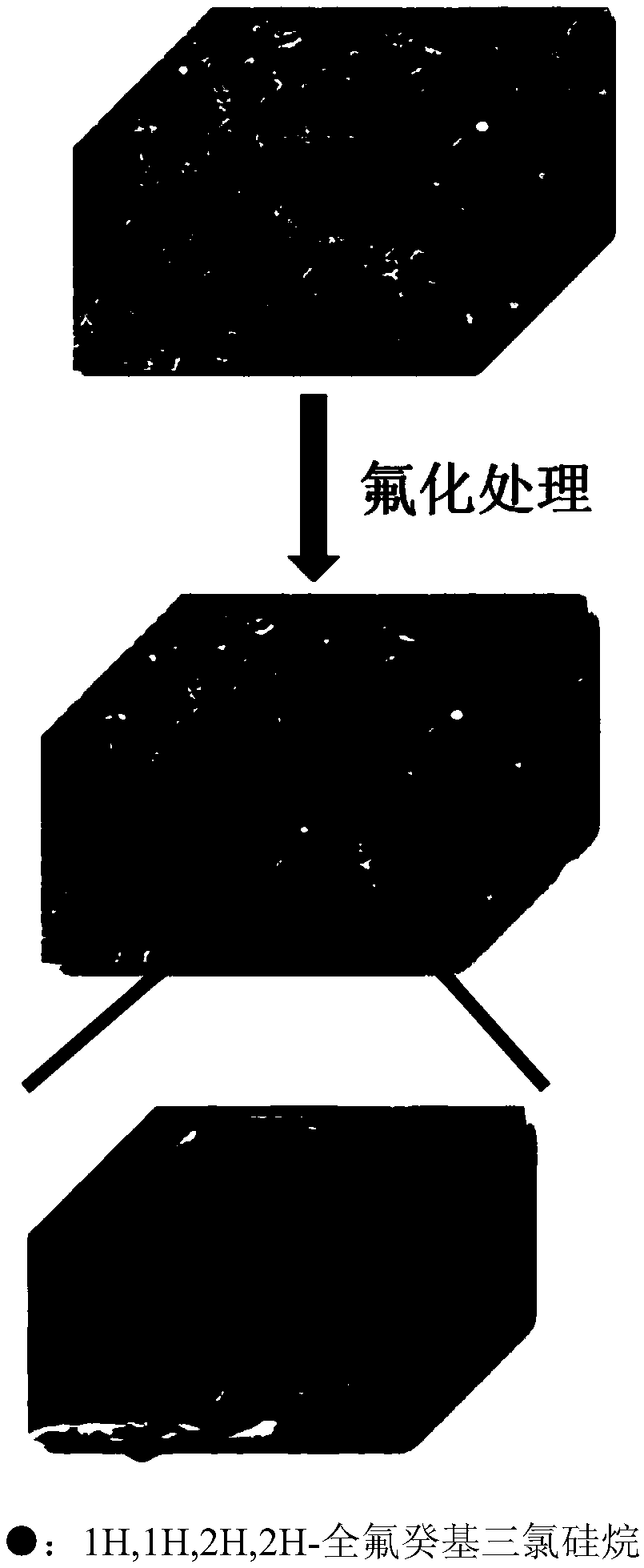

[0059] Hydrophobic and oleophobic substances are deposited on the surface of at least part of the carbon nanotubes forming the three-dimensional network structure, thereby forming an ultralight and ultrabuoyant carbon nanotube material.

[0060] In some embodiments, the chemical vapor deposition method includes: using small molecule alcohol as a carbon source, the deposition temperature is 700°C to 900°C, and the deposition time is greater than 0min and less than 120min, preferably 15min to 120min, more preferably 15min~60min.

[0061] In some implementation cases, the aforementioned carbon so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com