Method for preparing ceramic protection layer on C/SiC composite material, and ceramic protection layer prepared therethrough

A technology for composite materials and protective layers, which is applied in the field of ceramic protective layers, can solve the problems of reduced mechanical properties of composite materials, large differences in thermal expansion coefficients, and large differences in thermophysical properties, etc. binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

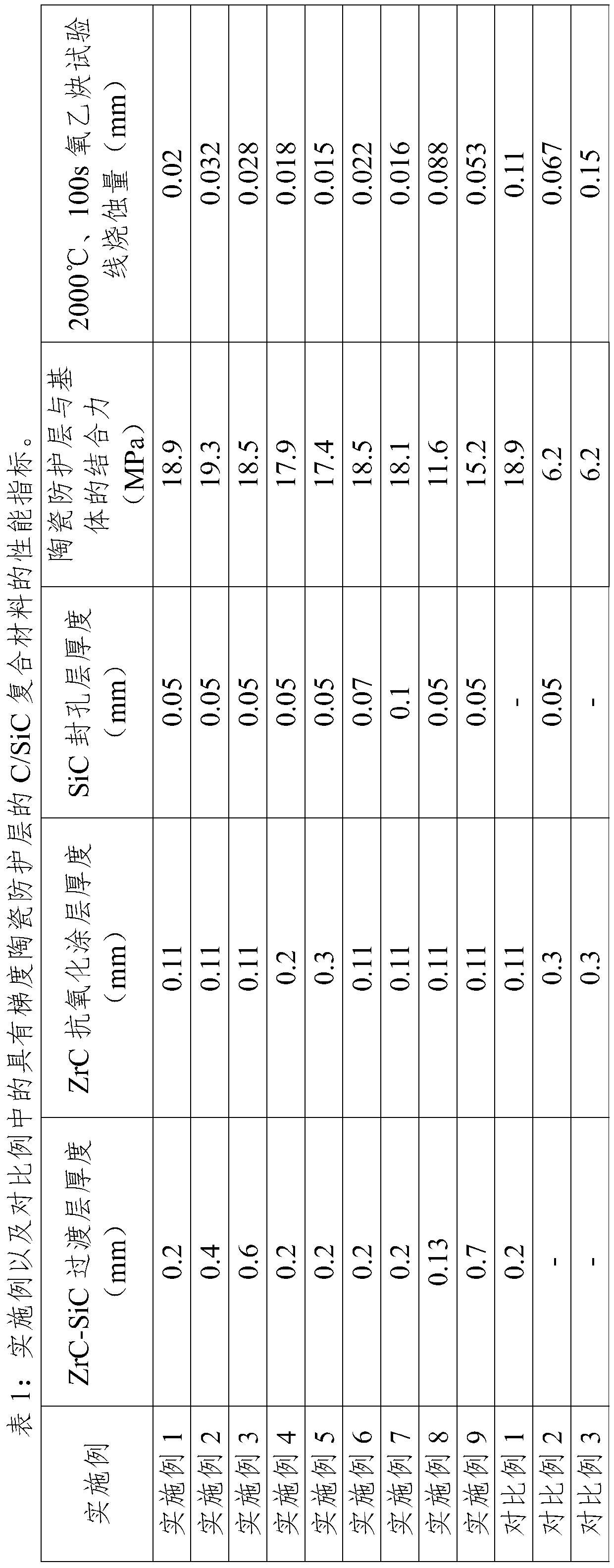

Examples

preparation example Construction

[0045] S2. Preparation of ZrC anti-oxidation coating: use zirconium precursor as solute, phenolic resin as carbon source, and xylene as solvent to prepare zirconium precursor resin solution; uniformly coat zirconium precursor resin solution in step S1 The surface of the C / SiC composite material with SiC and ZrC transition layers, after curing is completed, placed in a high temperature cracking furnace for high temperature cracking to obtain a ZrC oxidation resistant coating, specifically including the following steps:

[0046] S21. In parts by weight, add 1 part of zirconium precursor and 1.5-2.5 parts of aminophenol aldehyde into 2.5-3.5 parts of xylene, stir at room temperature for 5-10 hours, and prepare a zirconium precursor resin solution;

[0047] S22. Uniformly coat the zirconium precursor resin solution on the surface of the C / SiC composite material with SiC and ZrC transition layers in step S1, and then place the C / SiC composite material in a curing tank, under 1-3MPa ...

Embodiment 1

[0054] A preparation method of a C / SiC composite gradient ceramic protective layer, the specific steps of which are:

[0055] ①Preparation of SiC and ZrC ceramic transition layer: by weight, add 1 part of zirconium precursor (polycarbozirane), 1 part of polycarbosilane, 2 parts of aminophenol aldehyde to 3 parts of xylene, at 80 ° C Stir under high temperature for 10 hours to prepare a zirconium-silicon integrated ceramic precursor solution; place the C / SiC composite material in the zirconium-silicon integrated ceramic precursor solution, vacuum impregnate for 10 hours, and then cure at 250°C and 0.5MPa pressure for 5 hours; After impregnation and curing, the C / SiC composite material was placed in a high-temperature pyrolysis furnace and pyrolyzed at 1400 °C for 2 hours to obtain a C / SiC composite material with SiC and ZrC ceramic transition layers.

[0056]②Preparation of ZrC anti-oxidation coating: In parts by weight, 1 part of zirconium precursor (polycarbozircone) and 1.5 ...

Embodiment 2

[0060] A preparation method of a C / SiC composite gradient ceramic protective layer, the specific steps of which are:

[0061] ① Preparation of SiC and ZrC ceramic transition layers: by weight, 4 parts of zirconium precursor (polycarbozirane), 1 part of polycarbosilane, and 5 parts of aminophenol aldehyde were added to 9 parts of xylene, at a temperature of 80 ° C Stir under high temperature for 10 hours to prepare a zirconium-silicon integrated ceramic precursor solution; place the C / SiC composite material in the zirconium-silicon integrated ceramic precursor solution, vacuum impregnate for 10 hours, and then cure at 250°C and 0.5MPa pressure for 5 hours; After impregnation and curing, the C / SiC composite material was placed in a high-temperature pyrolysis furnace and pyrolyzed at 1400 °C for 2 hours to obtain a C / SiC composite material with SiC and ZrC ceramic transition layers.

[0062] ②Preparation of ZrC anti-oxidation coating: In parts by weight, 1 part of zirconium precu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com