Thermosetting resin composition and application thereof

A resin composition, thermoplastic resin technology, applied in the fields of prepreg, laminate and printed circuit laminate, thermosetting resin composition, can solve the problem of weakening the adhesion of reinforcing materials, decreasing the permeability, hindering copper clad laminates and other problems, to achieve the effect of eliminating the difficulty of impregnation of the filler, improving the treatment effect, and eliminating the adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the purpose, technical solutions and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the examples. It should be understood that the specific examples are only used to explain the present application, and are not intended to limit the present application.

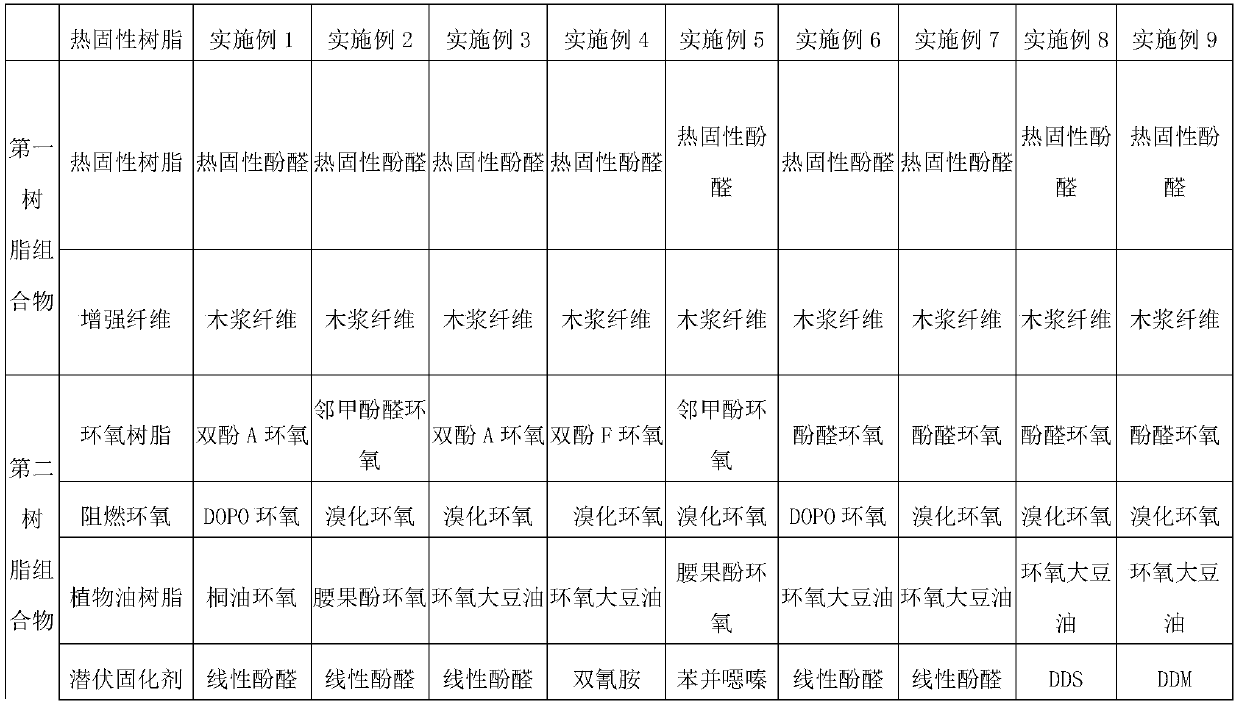

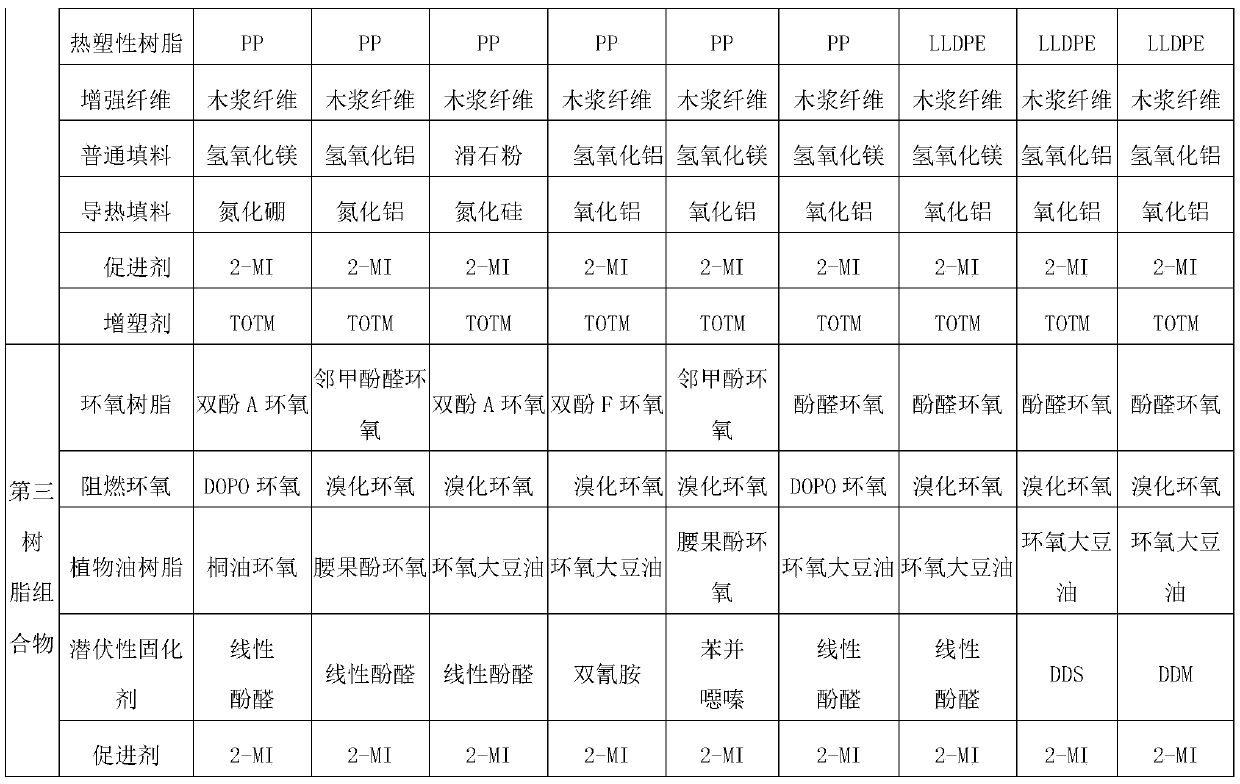

[0052] The thermosetting resin composition includes a first resin composition, a second resin composition and a third resin composition.

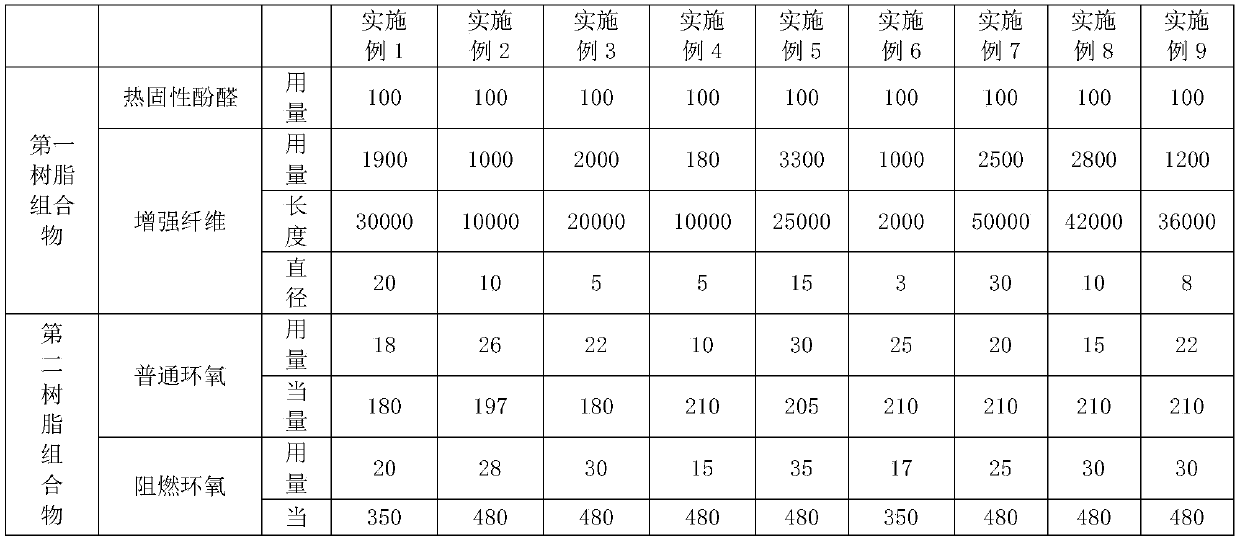

[0053] Each component of the first resin composition and its solid parts by weight are: 100 parts of thermosetting phenolic resin, 180-3300 parts of reinforcing fiber and an appropriate amount of solvent; each component of the second resin composition and its solid parts by weight are: epoxy 10-30 parts of resin, 15-35 parts of flame-retardant epoxy resin, 0.5-30 parts of latent curing agent, 5-25 parts of vegetable oil modified resin, 2-30 parts of thermoplastic resin, 10-800 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com