Jackfruit seed buccal tablet and preparation method thereof

The technology of jackfruit seeds and sweeteners is applied in the field of jackfruit seed lozenges and their preparation, which can solve the problems of excessively discarded seed kernels, low utilization rate of jackfruit seeds, and few deep-processed products, and achieves the effect of promoting weight loss, low calorie content, The effect of promoting energy metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Select fresh, plump and mature jackfruit seeds, wash them, and soak them in 0.02% salt water for 10 hours at 4°C. Jackfruit seeds were shelled, rinsed and sliced to a thickness of 0.3 cm, dried at 60°C for 2 hours. Pass through 80 mesh sieves after crushing to get jackfruit seed powder.

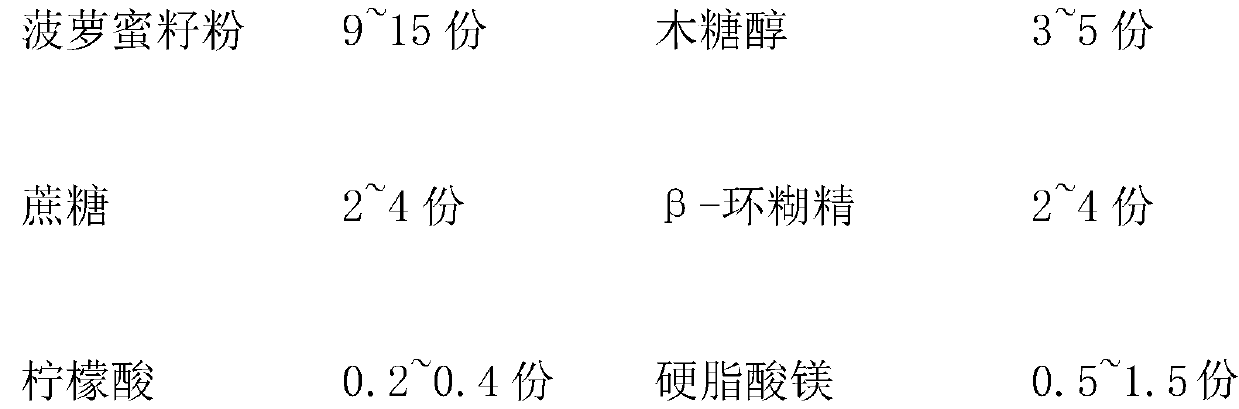

[0022] (2) After pulverizing xylitol, sucrose, β-cyclodextrin and citric acid, pass through an 80-mesh sieve respectively, and prepare materials according to the following parts by mass:

[0023]

[0024] (3) Making soft material: mix uniformly by each component distribution ratio of step (2). Slowly add 0.2 parts of 95% edible ethanol to the uniformly mixed material, knead while adding, and adjust the humidity of the material to make a soft material. The dry humidity of the soft material should be able to form a ball but not sticky when held tightly by hand, and it can be cracked by light pressure with fingers.

[0025] (3) Granulation: pass the prepared soft material thro...

Embodiment 2

[0030] (1) Select fresh, plump and mature jackfruit seeds, wash them, and refrigerate at 4°C for 12 hours. Jackfruit seeds were shelled, rinsed and sliced to a thickness of 0.2 cm, dried at 70°C for 1.5 hours. Sieve through an 80-mesh sieve after crushing to obtain jackfruit seed powder.

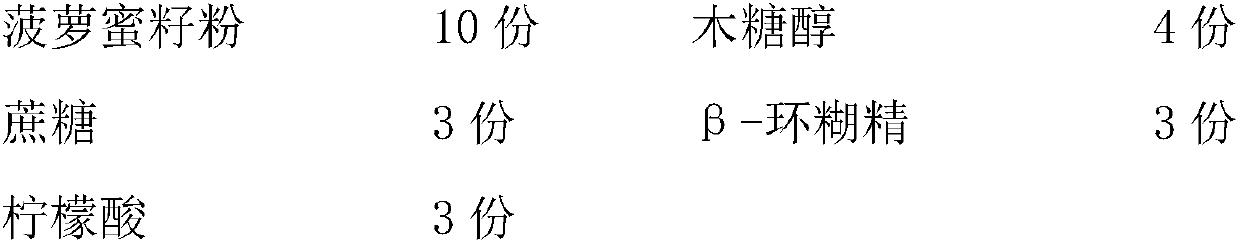

[0031] (2) After pulverizing xylitol, sucrose, β-cyclodextrin and citric acid, pass through an 80-mesh sieve respectively, and prepare materials according to the following parts by mass:

[0032]

[0033] (3) Making soft material: mix uniformly by each component distribution ratio of step (2). Slowly add 0.3 part of 95% edible ethanol to the uniformly mixed material, knead while adding, and adjust the humidity of the material to make a soft material. The dry humidity of the soft material should be able to form a ball but not sticky when held tightly by hand, and it can be cracked by light pressure with fingers.

[0034] (3) Granulation: pass the prepared soft material through a 20-me...

Embodiment 3

[0039] (1) Select fresh, plump and mature jackfruit seeds, wash them, and soak them in 0.02% salt water for 10 hours at 4°C. Jackfruit seeds were shelled, rinsed and sliced to a thickness of 0.5 cm, dried at 80°C for 1 hour. Pass through 80 mesh sieves after crushing to get jackfruit seed powder.

[0040] (2) After pulverizing xylitol, sucrose, β-cyclodextrin and citric acid, pass through an 80-mesh sieve respectively, and prepare materials according to the following parts by mass:

[0041]

[0042] (3) Making soft material: mix uniformly by each component distribution ratio of step (2). Slowly add 0.4 part of 95% edible ethanol to the uniformly mixed material, knead while adding, and adjust the humidity of the material to make a soft material. The dry humidity of the soft material should be able to form a ball but not sticky when held tightly by hand, and it can be cracked by light pressure with fingers.

[0043] (3) Granulation: pass the prepared soft material throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com