Embossing device applied to intermediate film of organic polymer for laminated glass

A technology of laminated glass and polymer, which is applied in the field of plastic processing, can solve the problems of uncontinuous production, interlayer pollution, and poor sheet thickness, etc., achieve excellent exhaust effect and anti-sticking ability, reduce deformation, and improve self-strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

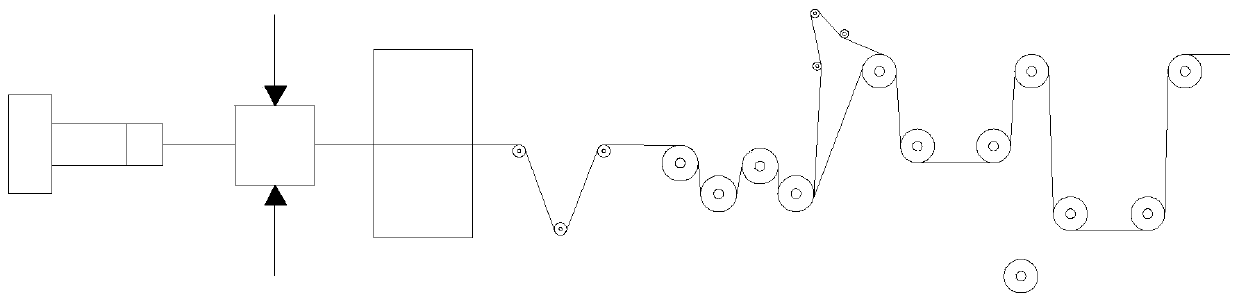

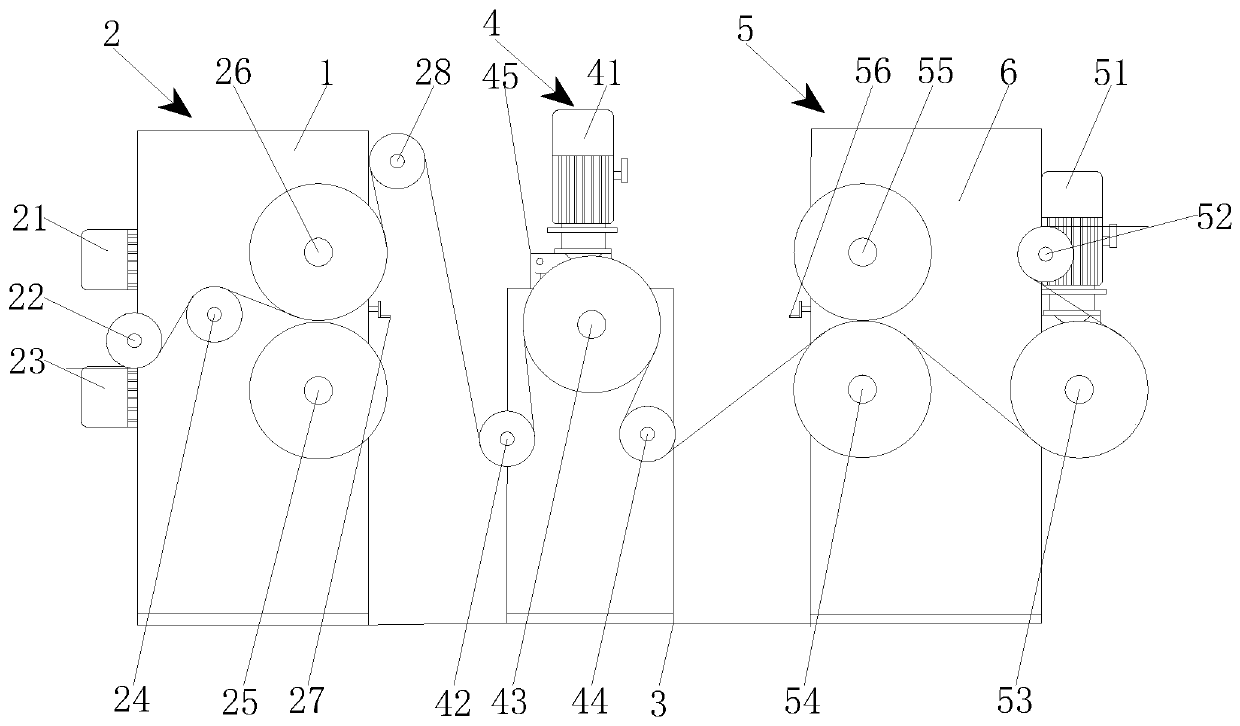

[0030] An embossing device applied to an organic polymer interlayer film for laminated glass, comprising a first embossing seat 1, a first embossing mechanism 2, a cooling seat 3, a cooling mechanism 4, a second embossing mechanism 5 and a second embossing mechanism Flower seat 6, the first embossing seat 1 is fixedly connected to the first embossing mechanism 2, the right side of the first embossing seat 1 is provided with a cooling seat 3, the cooling seat 3 is fixedly connected to the cooling mechanism 4, and the right side of the cooling seat 3 is provided with a second Two embossing seats 6, the second embossing seat 6 is fixedly connected to the second embossing mechanism 5;

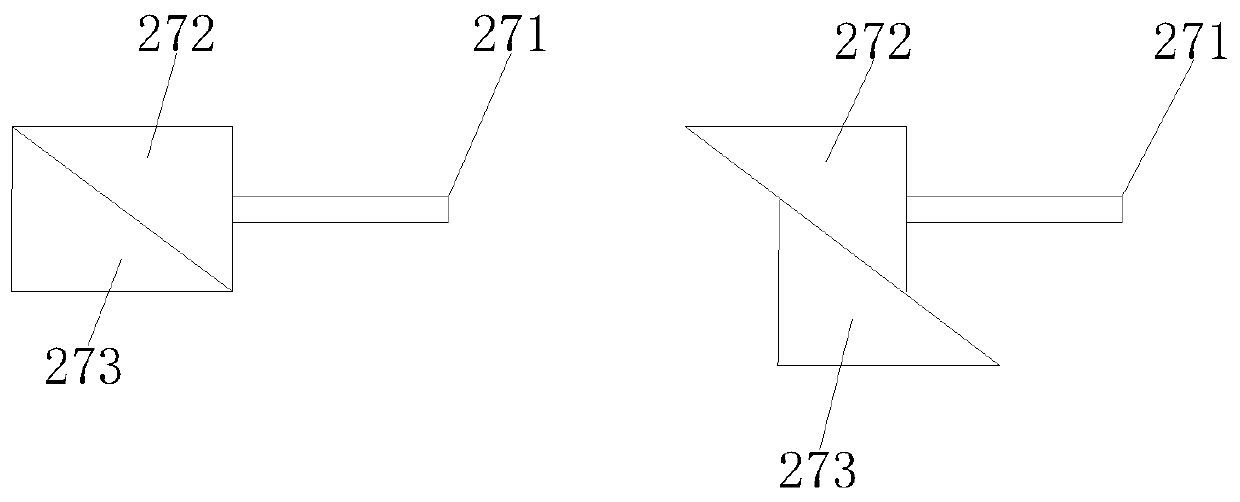

[0031]The first embossing mechanism 2 includes a first reduction motor 21, a first aluminum guide roller 22, a second reduction motor 23, a second aluminum guide roller 24, a first pattern roller 25, a first rubber roller 26, and a first roller spacing adjustment Device 27 and the third aluminum gu...

Embodiment 2

[0035] The organic polymer interlayer film is a PVB interlayer film with a thickness of 0.76mm, a width of 2500mm, a line speed of 20m / min, an initial surface temperature of 32°C upon reaching the aluminum guide roller 1, and an original surface roughness of RZ21. The PVB interlayer film enters the first patterned roller 25 through the lower surface of the first aluminum guide roller 22 and the upper surface of the second aluminum guide roller 24. The patterned roller is heated by heat conduction oil to control the surface temperature of 150°C. The pattern is engraved in the form of laser engraving. Inclined 45 degrees "well" shape, line spacing 0.3mm, pattern depth 0.2mm, hard chrome plating on the surface. The first rubber roller 26 is a smooth EPDM rubber stick with a roller surface hardness of 76. The interior is cooled by 30% ethylene glycol-70% refrigerated water, 8°C-10°C, and the surface temperature of the rubber roller is controlled at 30°C. Driven by the hydraulic p...

Embodiment 3

[0037] On the basis of the second embodiment, the temperature of the heat transfer oil is increased, and the surface temperature of the first patterned roller 25 and the second patterned roller 55 is increased to 170°C. The surface roughness RZ of the PVB interlayer film is 67. However, in the production process, there is a slight phenomenon that the PVB interlayer film sticks to the patterned roller, and there is a risk of film breakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com