Powder graphite and non-water electrolyte secondary cell

A non-aqueous electrolyte and secondary battery technology, applied in the direction of non-aqueous electrolyte batteries, secondary batteries, graphite, etc., can solve the problems of non-rechargeable and discharge, and achieve the effect of improving load characteristics and cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

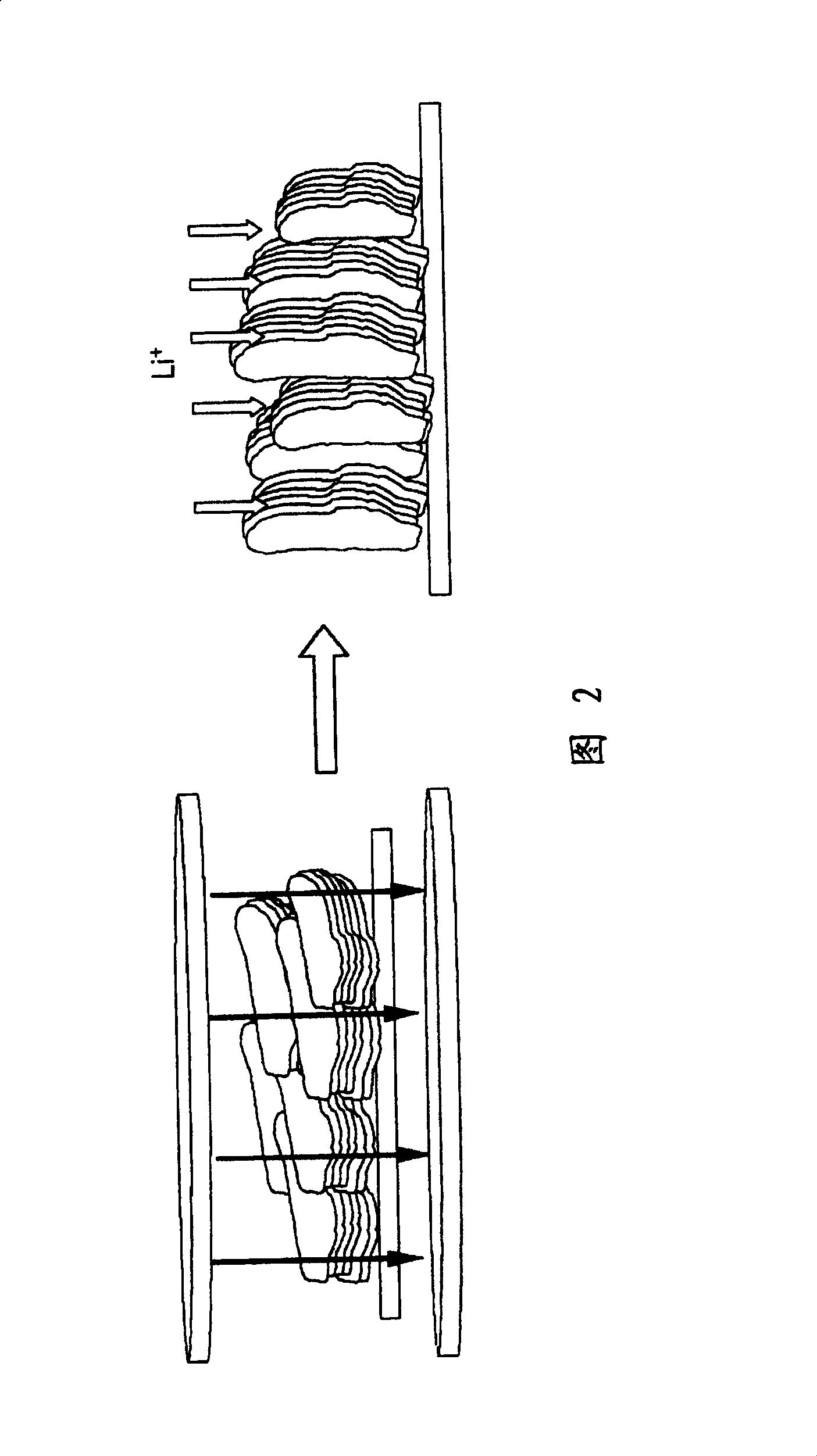

[0053] Samples 1, 2, and 3 were used to form negative electrodes, and subsequently, coin-type test cells were formed with and without magnetic field orientation. Next, measure the load characteristics of the battery.

[0054] [Formation of coin-type test battery]

[0055] To each of Samples 1, 2, and 3, styrene-butadiene rubber (SBR) was added as a binder to make the content 2% by weight, and carboxymethyl cellulose was added as a viscosity modifier to the above mixture to form a negative electrode mixture. The negative electrode mixture thus formed was then dispersed in water to obtain a slurry. To form an electrode, a strip-shaped copper foil having a thickness of 15 μm was used as a current collector, and the slurry of the negative electrode mixture was uniformly coated on both sides of the current collector. Immediately after the above coating, the electrodes not to be subjected to magnetic field orientation treatment were dried, followed by compression molding, and the...

Embodiment 2

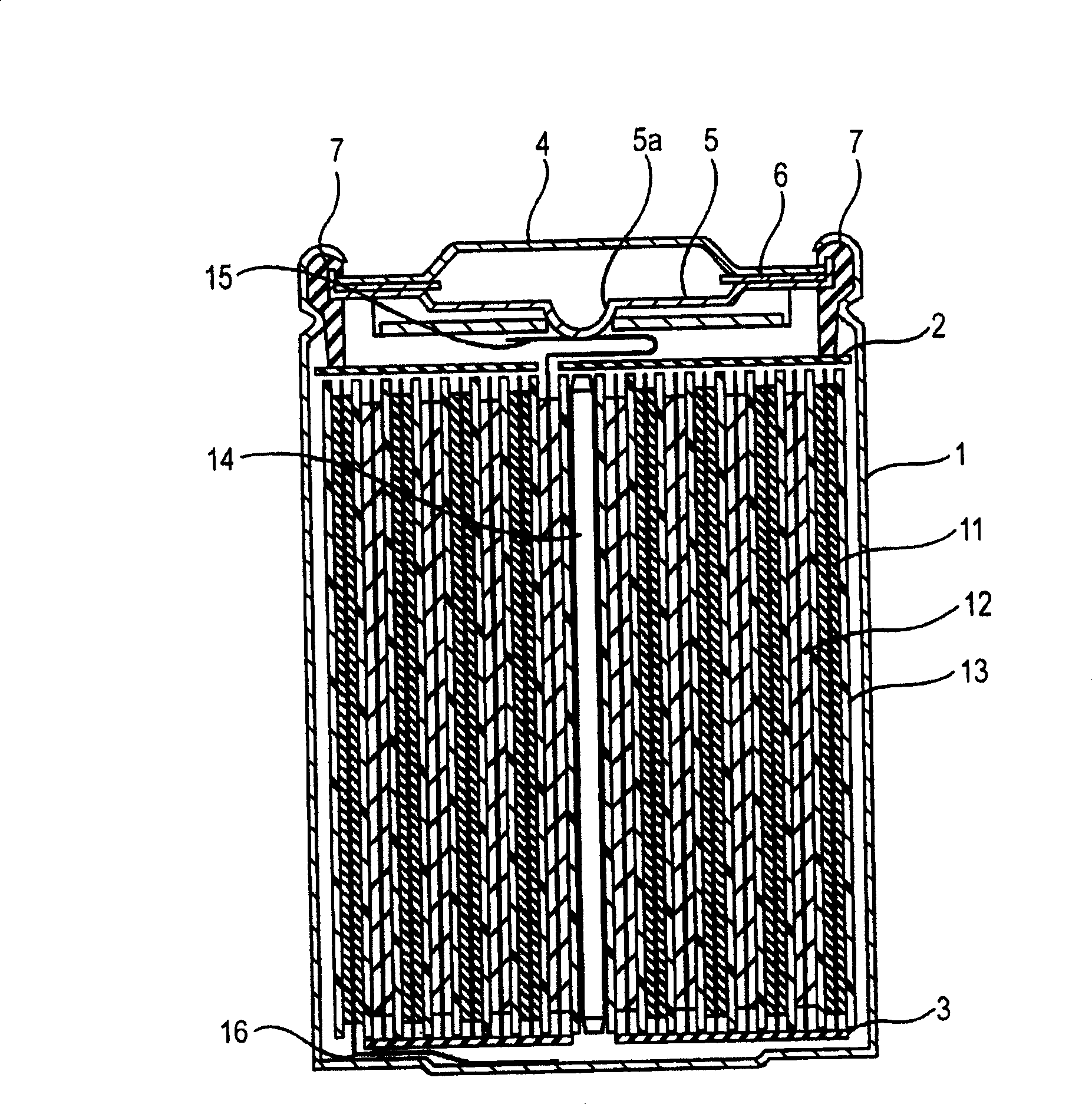

[0066] Using samples 1, 2 and 3 as the following negative electrode materials to form image 3The shown cylindrical non-aqueous electrolyte secondary battery with a diameter of 1.8 mm and a height of 65 mm was then subjected to a cycle test. As the cycle retention rate, the discharge capacity at initial charge was regarded as 100%, and the discharge capacity (%) obtained after 100 charge-discharge cycles was measured. Using each of the above-mentioned samples, a secondary battery in which the negative electrode was subjected to the magnetic field orientation treatment and a secondary battery in which the negative electrode was not subjected to the magnetic field orientation treatment were formed, and then their cycle retention ratios were measured.

[0067] [Formation of negative electrode]

[0068] In each of Samples 1, 2 and 3, styrene-butadiene rubber (SBR) was added as a binder to make its content 2% by weight, and then carboxymethyl cellulose was added as a viscosity mod...

Embodiment 3

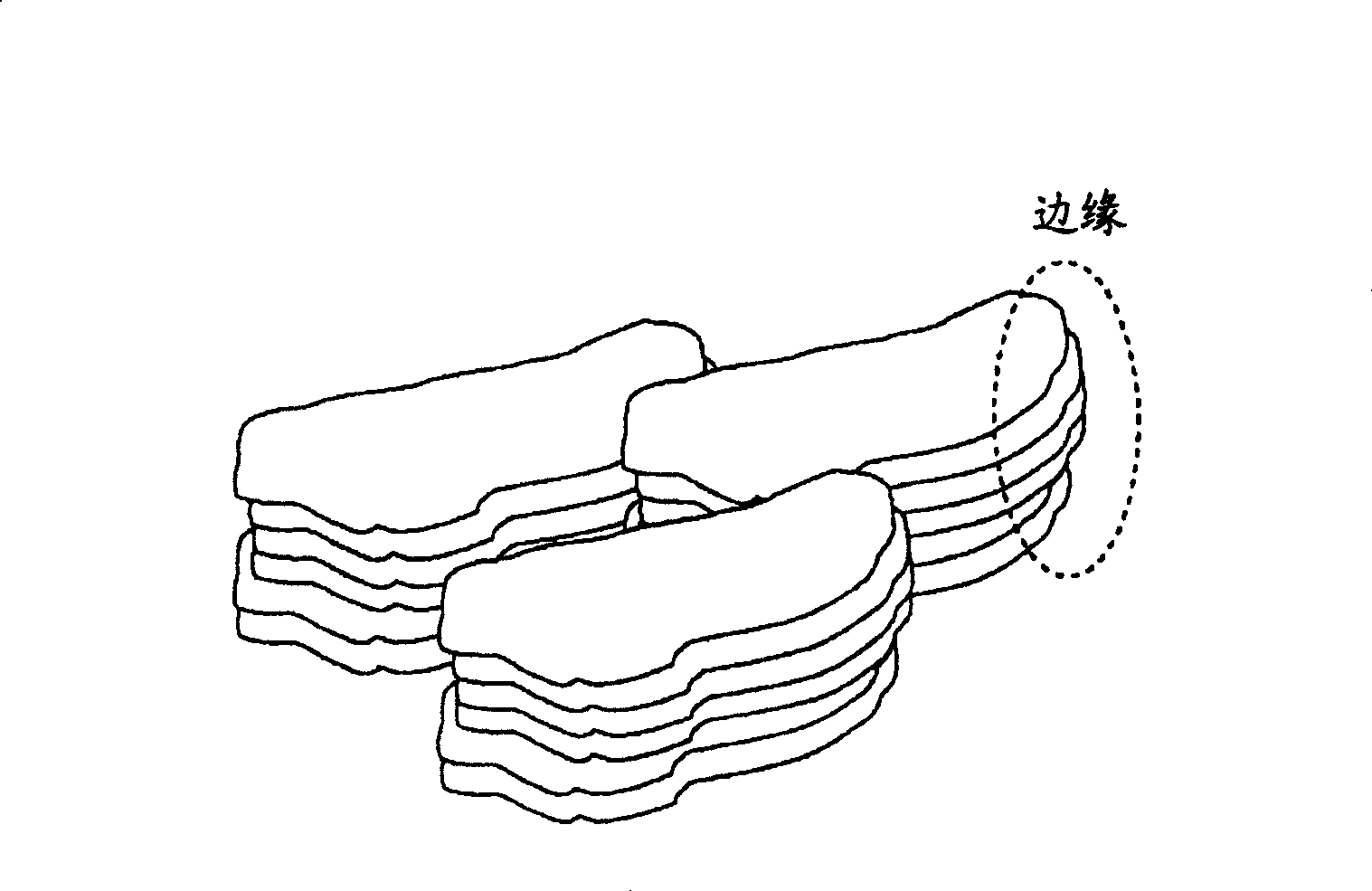

[0083] Specific surface areas of samples 2 and 3 were measured and compared with sample 1 composed of flaky graphite to measure the state of spheroidization. The specific surface area is measured by the BET method. The adsorption material in the measurement was nitrogen, and the degassing temperature and time were set to 120° C. and 30 minutes, respectively.

[0084] In Table 3 below, specific surface area values of Samples 1, 2 and 3 measured by the BET method are shown.

[0085] table 3

[0086] Specific surface area (m 2 / g) sample 1 4.83 sample 2 4.30 sample 3 3.60

[0087] From the above results, it can be seen that the specific surface area decreases as the grinding time using the impact type pulverizer increases, and therefore, it can be understood that the natural graphite particles are indeed spheroidized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com