One-pot synthesis technology of photo initiator 2,4-diethylthioxanthone

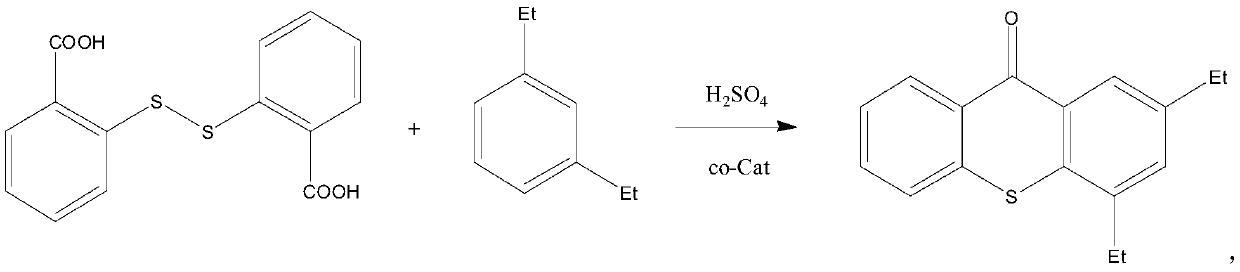

A technology of diethylsulfide and xanthone, which is applied in the technical field of one-pot synthesis of photoinitiator 2,4-diethylthioxanthone, which can solve the problem of low equipment utilization and labor efficiency, and the appearance of products containing Problems such as variegated color and difficult post-processing can be achieved to improve product quality, reduce raw material costs, and increase single-pot efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 40 ml of concentrated sulfuric acid, 100 g of dithiosalicylic acid, and 8 g of polyphosphoric acid into a 500 ml four-necked reaction flask, cool to below 0°C in an ice-salt bath while stirring, and add 1,3-diethylbenzene dropwise 100 grams, the reaction temperature is controlled not to exceed 5°C. After the addition, the ice-salt bath was removed, and the temperature was naturally raised to room temperature, and the reaction was continued for 1 hour. Replace the oil bath, slowly raise the temperature to 65° C., and react at 65° C. for 5 hours. Follow the reaction by HPLC until the reaction of dithiosalicylic acid is complete. Cool the reaction product, add 90 grams of 1,3-diethylbenzene and 60 grams of water, stir for half an hour, let stand to separate the phases, wash the organic phase with alkali and water, concentrate, and then cool to 5°C overnight, the next day Filtrate, wash the filter cake with a small amount of ice ethanol, and vacuum-dry to obtain 150 gr...

Embodiment 2

[0030] Add 40 ml of concentrated sulfuric acid, 2 g of phosphorus pentoxide and 16 g of methanesulfonic acid into a 500 ml four-necked reaction flask, stir evenly, then add 100 g of thiosalicylic acid, and cool to 0°C in an ice-salt bath while stirring Next, 100 grams of 1,3-diethylbenzene was added dropwise, and the reaction temperature was controlled not to exceed 5°C. After the addition, the ice-salt bath was removed, and the temperature was naturally raised to room temperature, and the reaction was continued for 1 hour. Put on an oil bath, slowly heat up to 65°C, react at 65°C for 5 hours, follow the reaction by HPLC until the reaction of dithiosalicylic acid is complete, cool down, add 90 grams of toluene, 60 grams of water, stir for half an hour, and wait The phases were separated, and the organic phase was washed with alkali and water, and concentrated. Add anhydrous methanol and activated carbon to the residue, raise the temperature to 45°C and stir for half an hour, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com