Preparation method of PANI/MXene/carbon cloth composite wave absorbing material

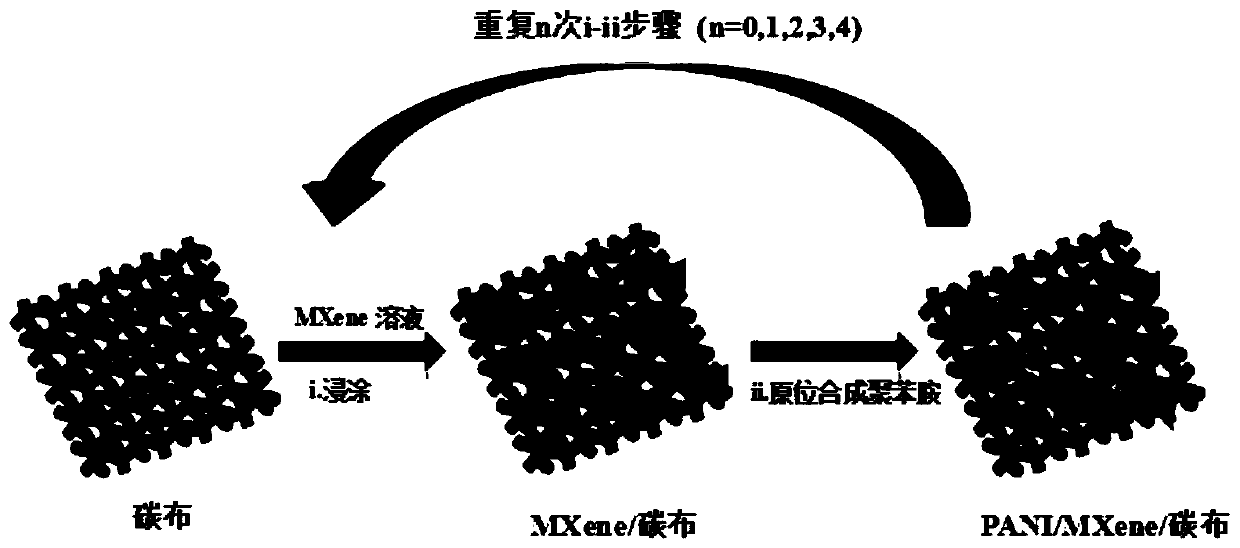

A composite wave absorbing material and composite material technology are applied in the field of preparation of PANI/MXene/carbon cloth composite wave absorbing materials, which can solve the problem of poor adhesion between wave absorbing coatings and textiles, damage to the original performance of the substrate, and the feel of coated fabrics. Stiffness and other problems, to achieve the effect of improving bonding fastness, improving bonding force, excellent electrical conductivity and wave absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) According to carbon cloth (100g / m 2 , 0.25g) and the nitric acid solution mass ratio is 1:50, the carbon is placed in the nitric acid aqueous solution with a mass concentration of 10wt%, stirred at room temperature for 10min, the fabric is taken out, washed with water, and dried.

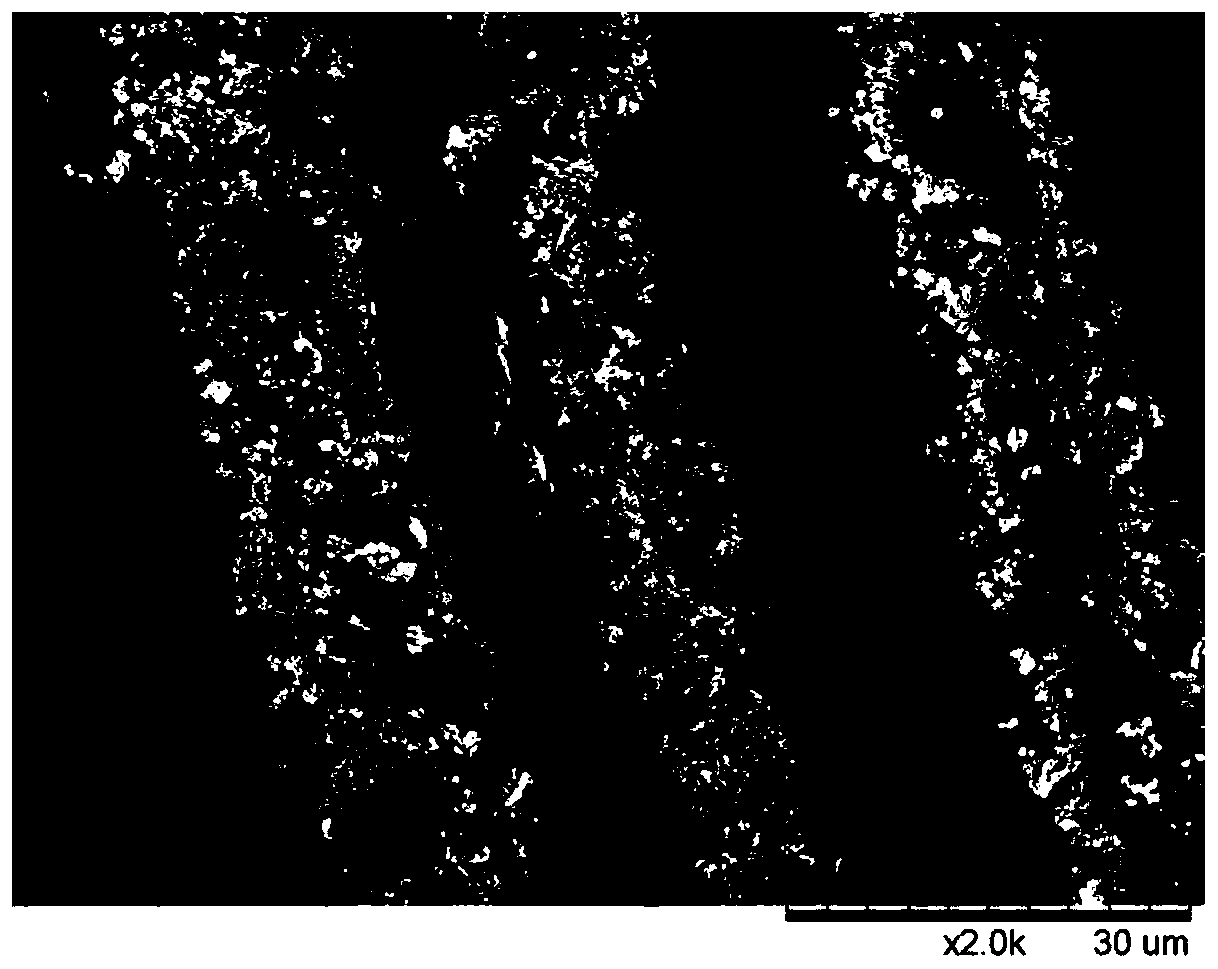

[0035] (2) According to the acidified carbon cloth (0.24g) and MXene (Ti 3 C 2 Tx, monolayer) solution with a mass ratio of 1:10, arrange the carbon treated in step (1) in a 5mg / mL MXene solution, stir at room temperature for 10min, then take out the fabric, wash it with water, and place it at 40°C Under drying to obtain MXene / carbon cloth.

[0036](3) According to the mass ratio of MXene / carbon cloth to aniline acid solution of 1:100, place MXene / carbon cloth (0.25g) in nitric acid (0.1mol / L) solution containing 0.1mol / L aniline, room temperature Stir for 20min, then add ammonium persulfate equimolar to aniline (0.005mol) for in-situ polymerization, react at room temperature for 2h, a...

Embodiment 2

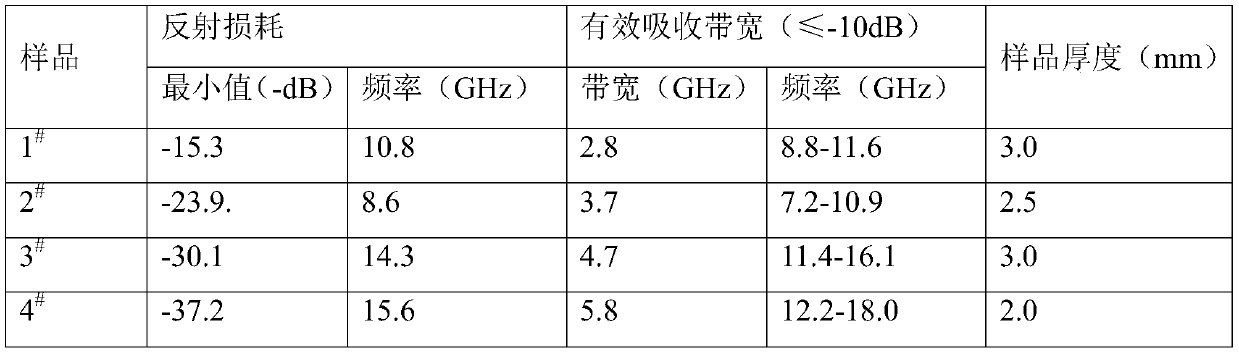

[0038] According to Example 1, repeat step (2) and step (3) in Example 1 twice, and the prepared PANI / MXene / carbon cloth composite absorbing material is designated as sample 2 # .

Embodiment 3

[0040] According to Example 1, repeat step (2) and step (3) in Example 1 three times, the prepared PANI / MXene / carbon cloth composite absorbing material is recorded as sample 3 # .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Minimum reflection loss value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com