Biomass coal water slurry prepared by combining phenolic wastewater and biomass charcoal, and production method and production system for biomass coal water slurry

A technology of biomass charcoal and joint preparation, which is applied in liquid carbon-containing fuels, petroleum industry, fuel additives, etc. Simple, stability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

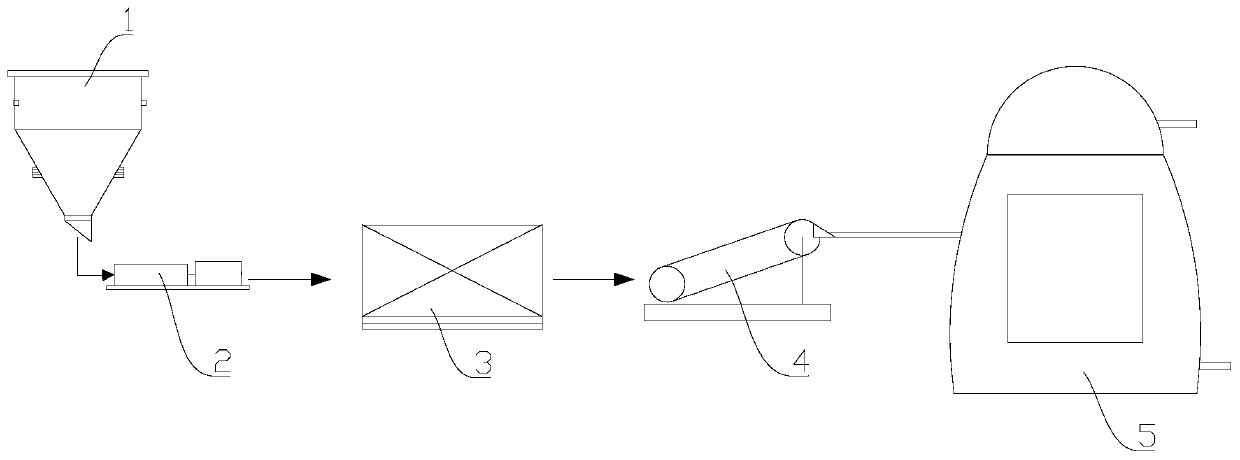

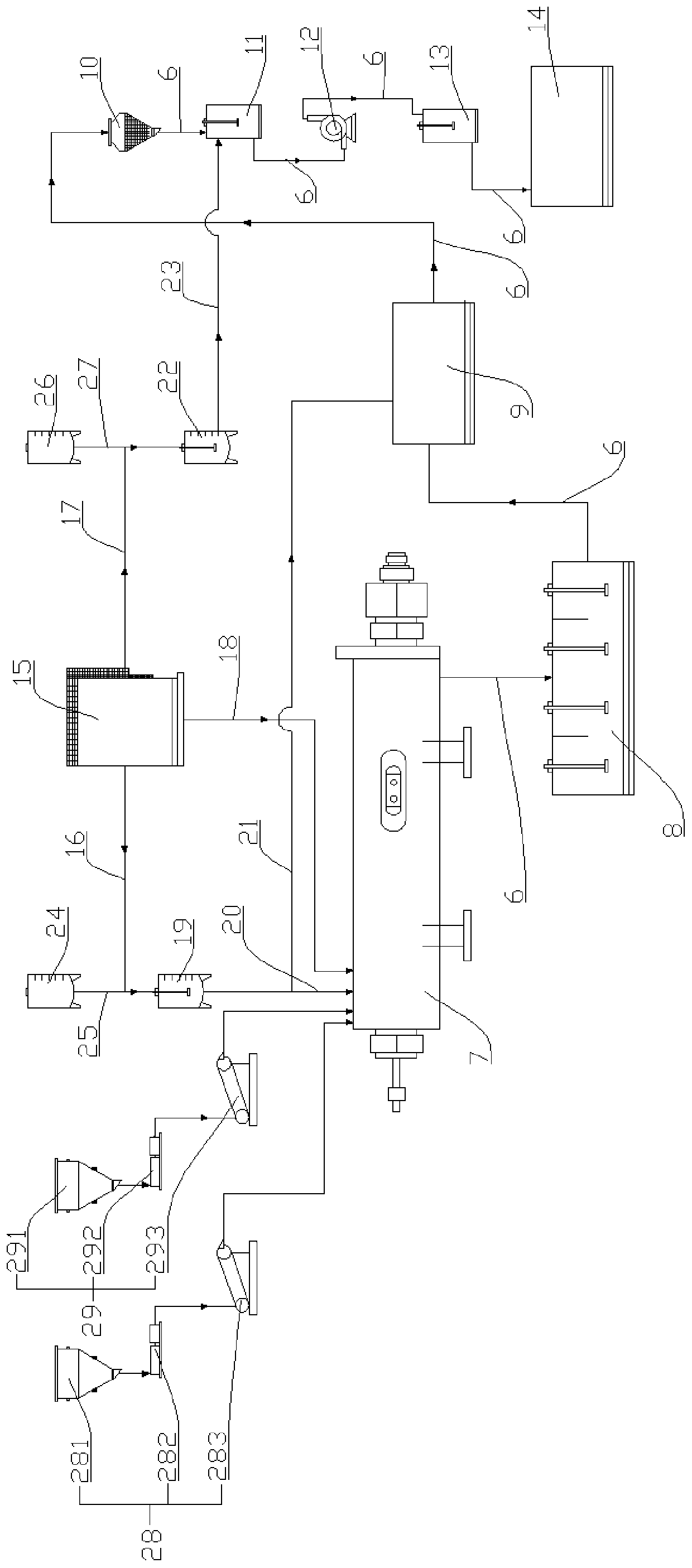

Method used

Image

Examples

Embodiment 1

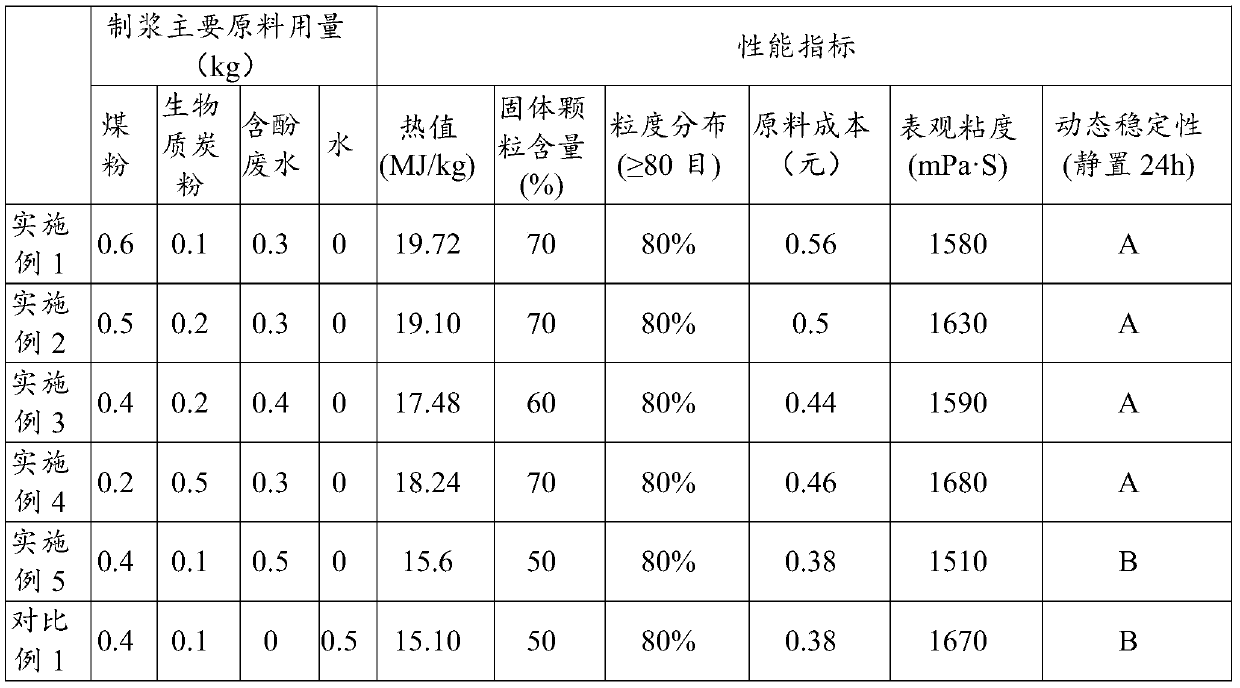

[0053] Biomass coal-water slurry prepared by combining phenolic wastewater and biochar, consists of the following components: 0.6kg coal powder, 0.1kg biochar powder, 0.3kg phenolic wastewater, 0.003kg dispersant, stabilizer 0.007kg; Among them, the volatile phenol content in phenol-containing wastewater is 3000mg / L, and the non-volatile phenol content is 500mg / L.

[0054] The production method of above-mentioned biomass coal-water slurry, comprises the steps:

[0055] (1) Prepare medicament: adopt part of phenol-containing wastewater to prepare dispersant and stabilizer respectively into dispersant dilution and stabilizer dilution; wherein, the mass percent concentration of dispersant dilution is 15%, and the mass percent of stabilizer dilution The concentration is 25%;

[0056] (2) Refining: Put coal powder, biomass charcoal powder, remaining phenolic waste water, and dispersant diluent accounting for 90% of the total amount of dispersant diluent into the mill 7 for grindin...

Embodiment 2

[0059] Biomass coal-water slurry prepared jointly with phenolic wastewater and biochar, consists of the following components: 0.5kg of coal powder, 0.2kg of biomass charcoal powder, 0.3kg of phenolic wastewater, 0.005kg of dispersant, stabilizer 0.005kg; Among them, the volatile phenol content in phenol-containing wastewater is 3000mg / L, and the non-volatile phenol content is 500mg / L.

[0060] The production method of above-mentioned biomass coal-water slurry, comprises the steps:

[0061] (1) Prepare medicament: adopt part of phenol-containing wastewater to prepare dispersant and stabilizer respectively into dispersant dilution and stabilizer dilution; wherein, the mass percent concentration of dispersant dilution is 15%, and the mass percent of stabilizer dilution The concentration is 25%;

[0062] (2) Refining: Put coal powder, biomass charcoal powder, remaining phenolic waste water, and dispersant diluent accounting for 90% of the total amount of dispersant diluent into t...

Embodiment 3

[0065] Biomass coal-water slurry prepared by combining phenolic wastewater and biochar, consists of the following components: 0.4kg coal powder, 0.2kg biochar powder, 0.4kg phenolic wastewater, 0.003kg dispersant, stabilizer 0.007kg; Among them, the volatile phenol content in phenol-containing wastewater is 3000mg / L, and the non-volatile phenol content is 500mg / L.

[0066] The production method of above-mentioned biomass coal-water slurry, comprises the steps:

[0067] (1) Prepare medicament: adopt part of phenol-containing wastewater to prepare dispersant and stabilizer respectively into dispersant dilution and stabilizer dilution; wherein, the mass percent concentration of dispersant dilution is 15%, and the mass percent of stabilizer dilution The concentration is 25%;

[0068] (2) Refining: Put coal powder, biomass charcoal powder, remaining phenolic waste water, and dispersant diluent accounting for 85% of the total amount of dispersant diluent into the mill 7 for grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com