Preparation method of electrocatalyst with multiple defects and active sites

A technology of active sites and electrocatalysts, which is applied in the field of electrocatalyst preparation, can solve the problems of expensive metal catalysis, low electrocatalytic efficiency, and complicated preparation of electrodes, and achieve the goal of optimizing interfacial transmission resistance, simple process, and rich contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

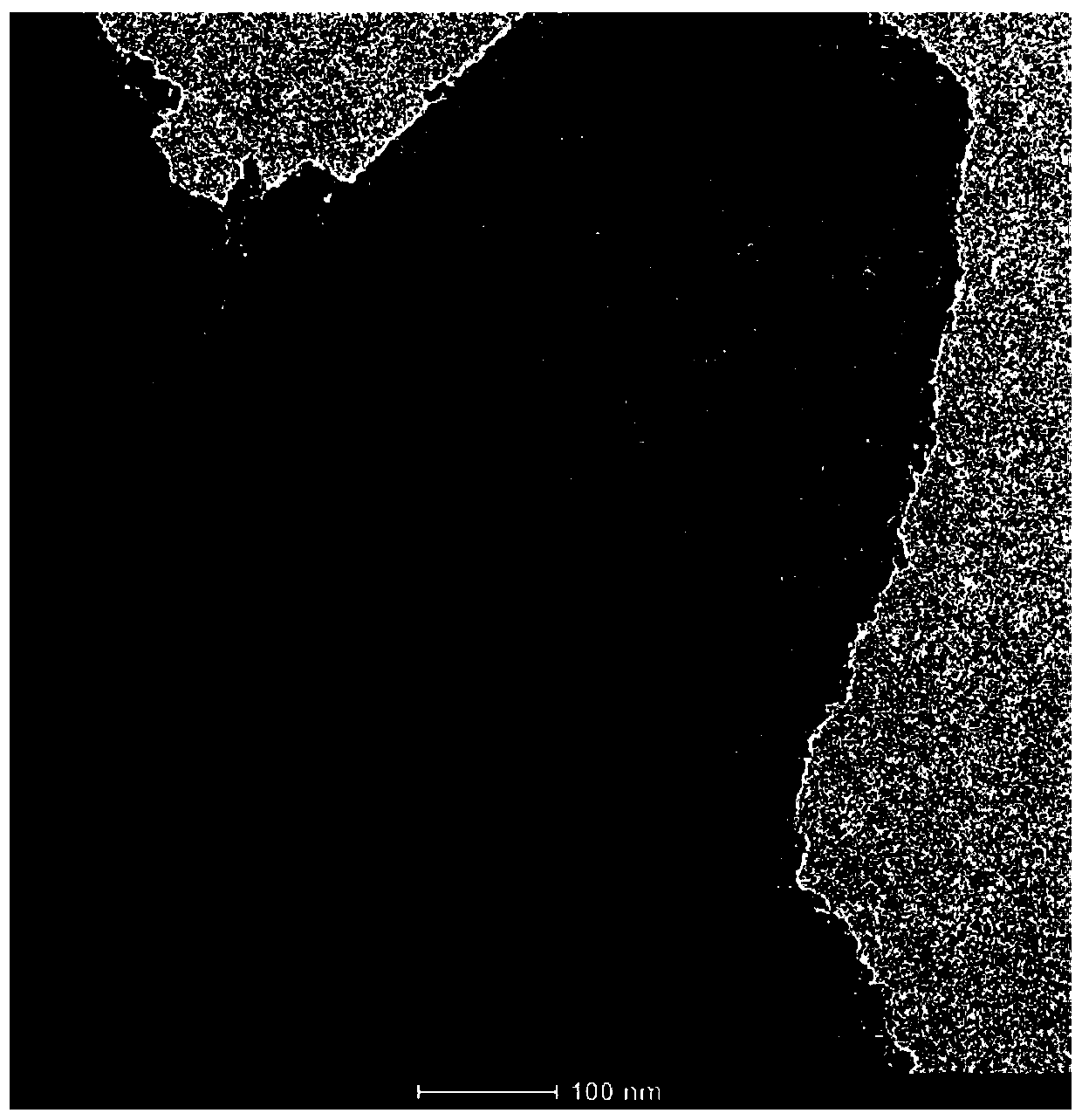

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: the preparation method of the electrocatalyst of a kind of multi-defect and active site described in this embodiment, it is finished according to the following steps:

[0017] 1. Stir and dissolve the metal salt, ammonium fluoride and urea in deionized water to obtain a mixed solution;

[0018] The concentration of metal salt in the mixed solution is 1mmol / L~500mmol / L; the concentration of ammonium fluoride in the mixed solution is 1mmol / L~200mmol / L; the concentration of urea in the mixed solution is 10mmol / L~1000mmol / L;

[0019] 2. Clean the conductive substrate, then immerse it in the mixed solution, keep it warm for 1h-24h at a temperature of 90°C to 180°C, and then cool it naturally to obtain a conductive substrate with precursors grown on it;

[0020] 3. Place the reaction source and the conductive substrate grown with the precursor in two temperature zones of the chemical vapor deposition device, and raise the temperature of the reaction...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the cleaning of the conductive substrate described in step 2 is carried out according to the following steps: the conductive substrate is ultrasonically Wash for 1min to 5min, then ultrasonically clean with ethanol and water for 1min to 5min, and finally air dry for later use. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the conductive substrate described in step two is carbon cloth, carbon paper, foamed nickel, foamed copper, foamed cobalt, foamed iron, foamed nickel Iron, nickel foil, iron foil, copper foil, cobalt foil or nickel-iron alloy foil. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com