Garlic deep processing and comprehensive utilization process and device thereof

A technology for deep processing and garlic, applied in the field of garlic deep processing and comprehensive utilization technology and devices, can solve the problems of poor sales, low utilization rate of production equipment, small audience, etc., to achieve product traceability, ensure product quality, and save volatilization losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

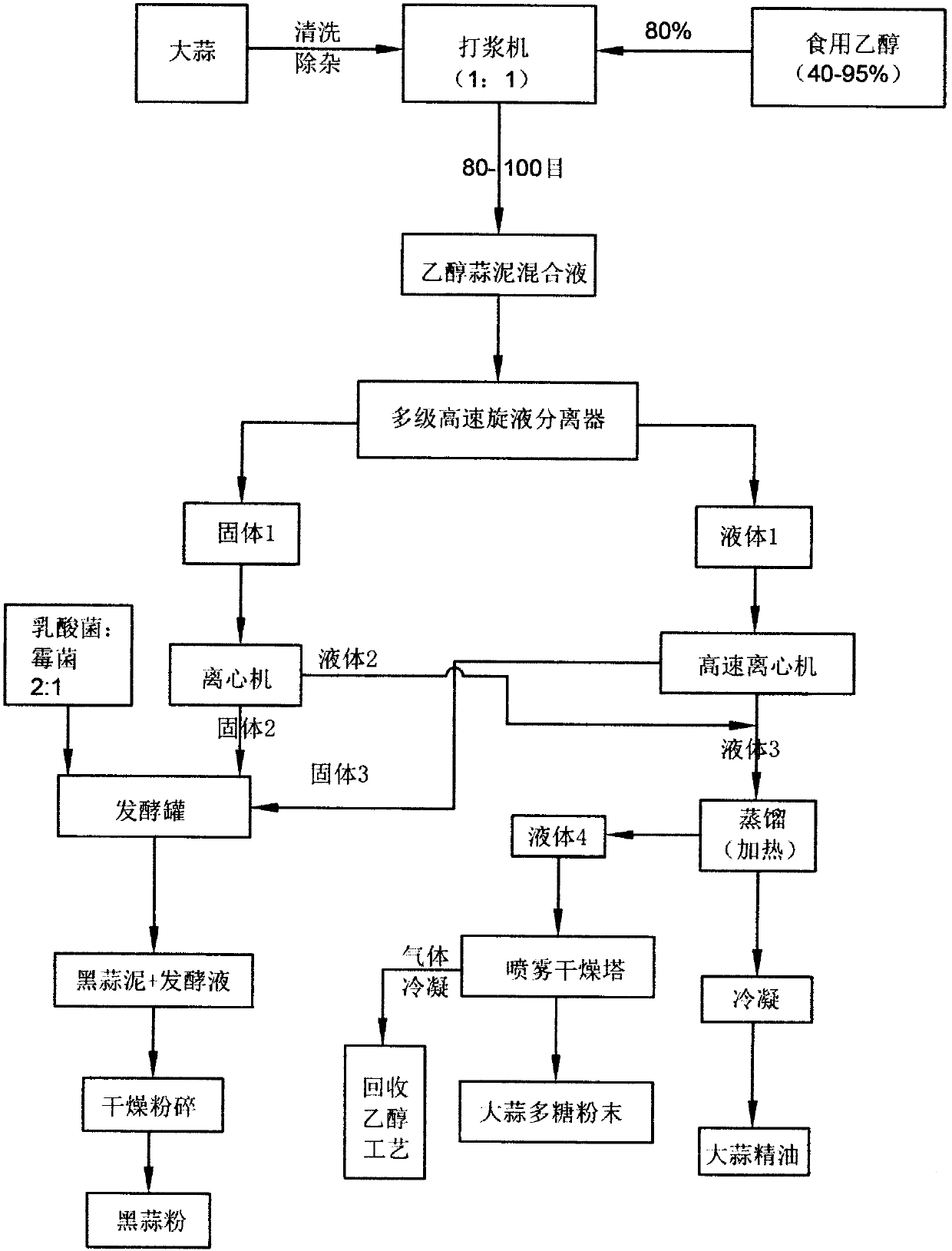

[0029] A garlic deep processing and comprehensive utilization technology, such as figure 1 shown, including the following steps:

[0030] 1) After concentrated cleaning, impurity removal, and drying of the harvested garlic, mixed with garlic and 80% edible ethanol solution in a weight ratio of 1:1 and sent to a beater, pulverized through an 80-100 mesh sieve, and placed in a raw material tank at room temperature. Airtight preservation, spare;

[0031] 2) liquid 1 and solid 1 are separated by multi-stage hydrocyclone and high-speed centrifuge by ethanol garlic paste mixed liquor;

[0032] 3) solid 1 is introduced into a centrifuge for further separation to obtain liquid 2 and solid 2; Liquid 1 is introduced into a high-speed centrifuge for further separation to obtain liquid 3 and solid 3;

[0033] 4) above-mentioned solid 2 and solid 3 are mixed and inoculated with lactic acid bacteria and mould 2: 1 mixed fermentation, obtain black garlic paste and fermented liquid mixture,...

Embodiment 2

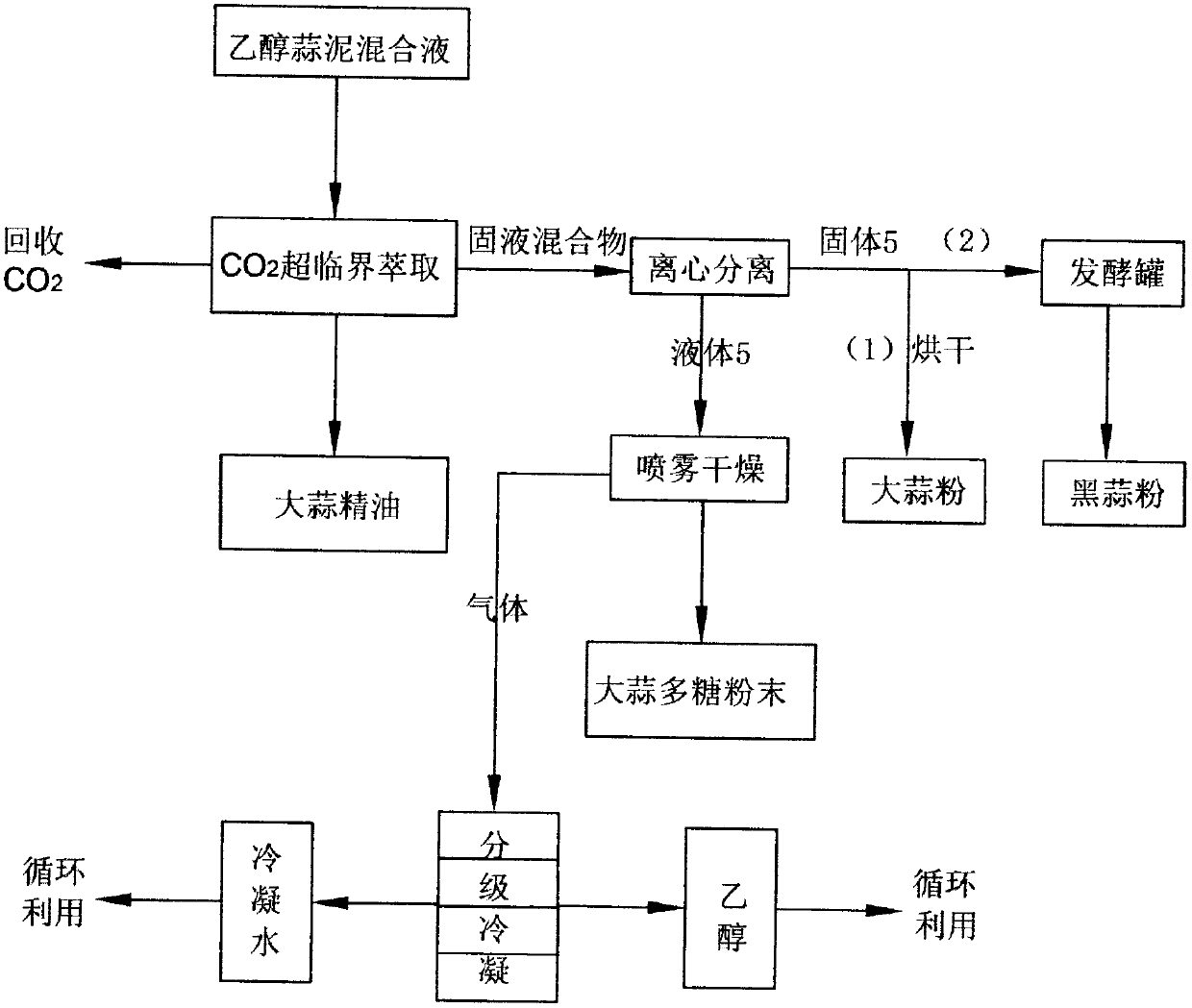

[0037] A garlic deep processing and comprehensive utilization technology, such as figure 2 shown, including the following steps:

[0038] 1) After concentrated cleaning, impurity removal and drying of the harvested garlic, mixed with garlic and 95% edible ethanol solution in a weight ratio of 1:1.5 and sent to a beater, pulverized through an 80-100 mesh sieve, and placed in a raw material tank at room temperature Airtight preservation, spare;

[0039] 2) the ethanol garlic paste mixture can be directly passed through high pressure CO supercritical extraction, obtain garlic essential oil, and solid-liquid mixture;

[0040] 3) above-mentioned solid-liquid mixture centrifuge is separated to obtain liquid 4 and solid 4;

[0041] 4) liquid 4 is spray-dried to obtain garlic polysaccharide powder, and gas;

[0042] 5) directly drying above-mentioned solid 4 to obtain garlic powder, or further fermenting above-mentioned solid 4 to prepare black garlic powder;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com