Molecular sieve with rich aluminum on surface, preparation method and applications thereof, and isomerization reaction catalyst and applications thereof

A molecular sieve and isomerization technology, applied in the field of molecular sieve, can solve the problem that high activity and high isomeric selectivity cannot be obtained at the same time, and achieve the effects of high isomeric selectivity, good application prospect and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention provides a first aspect of the present invention provides a method for preparing a surface aluminum-rich molecular sieve, the method comprising:

[0023] (1) Precursor gels A and B are prepared, the silicon-aluminum ratio of the precursor gel A is 40-100, the silicon-aluminum ratio of the precursor gel B is 100-400, and the silicon-aluminum ratio of the two is different;

[0024] (2) Carrying out the first step of crystallization of the precursor gels A and B respectively;

[0025] (3) The crystallization products of the first step prepared by the precursor gels A and B were mixed at a mass ratio of 1: (3-50) for the second step of crystallization, and finally the surface aluminum-rich molecular sieve was obtained.

[0026] Herein, the silicon-aluminum ratio refers to the molar ratio of silicon oxide to aluminum oxide.

[0027] In the present invention, the silicon-aluminum ratio of the precursor gel A can be 40, 45, 50, 55, 60, 65, 70, 75, 80, 85...

Embodiment approach

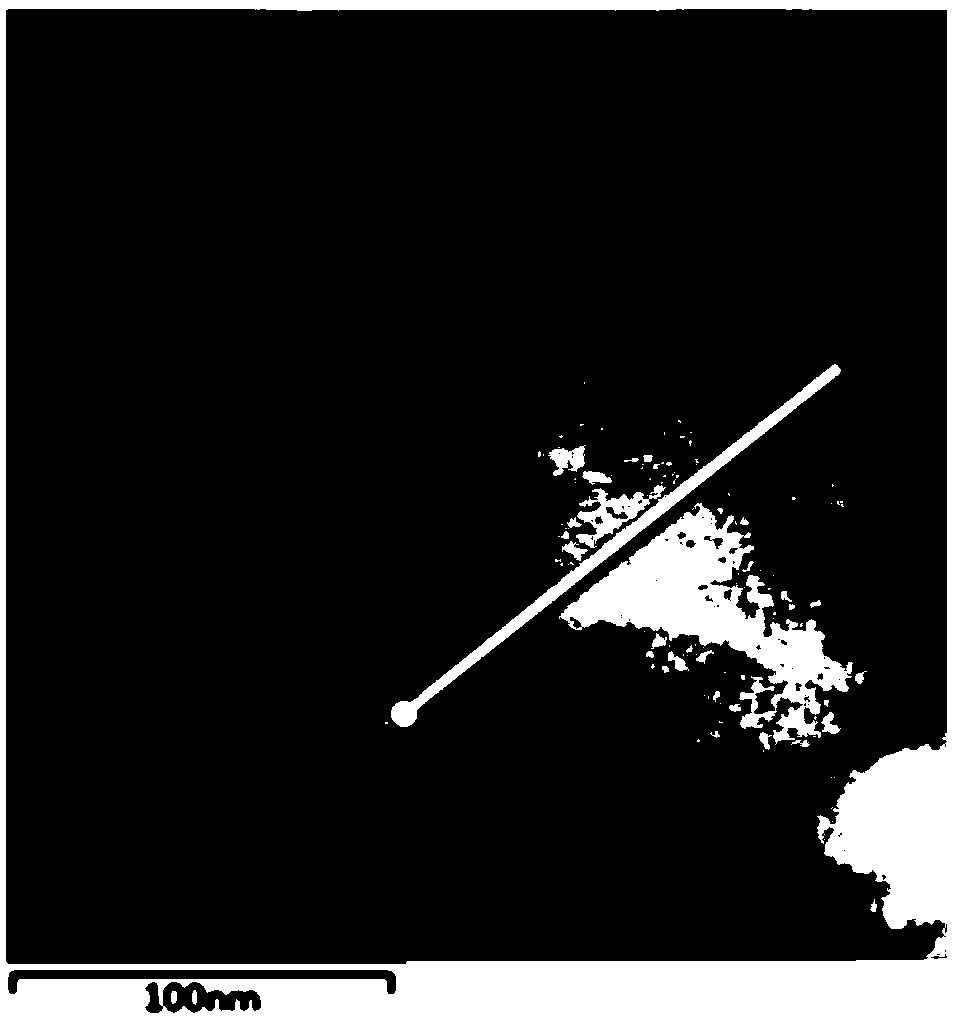

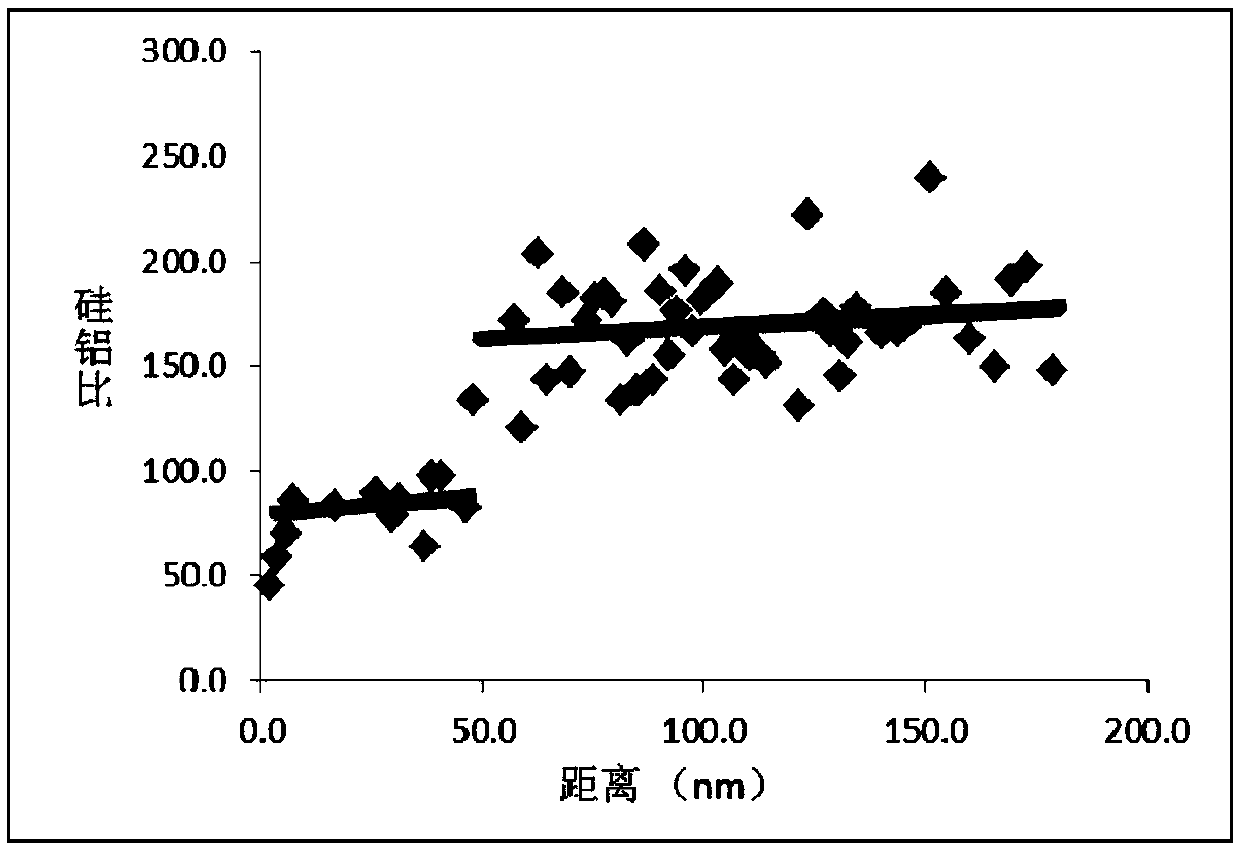

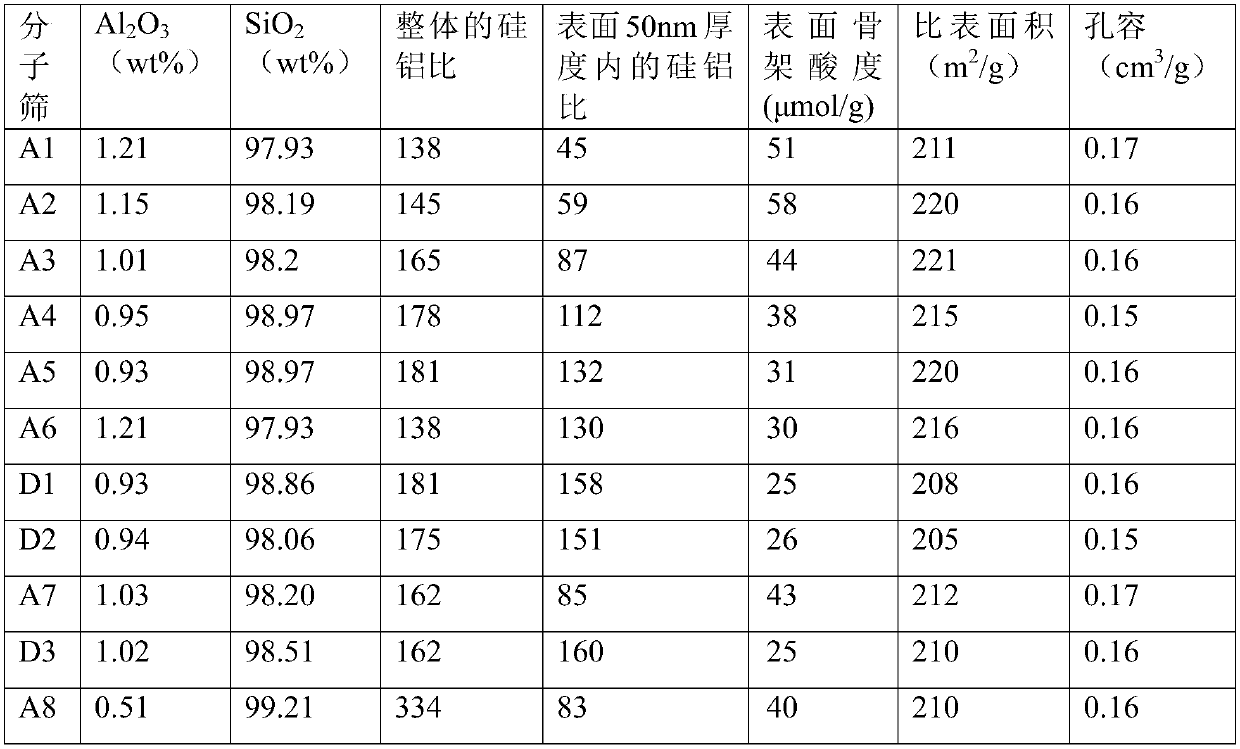

[0043] According to one embodiment, the ZSM-48 molecular sieve prepared by the method has a silicon-aluminum ratio of 150-300 as a whole of the molecular sieve, and a silicon-aluminum ratio of 40-150 within a thickness of 50 nm of the particle surface of the molecular sieve, preferably For 40-90. Here, the "within a thickness of 50 nm from the particle surface" should be understood as a thickness range of 50 nm from the particle surface.

[0044] According to one embodiment, the specific surface area of the molecular sieve prepared by the method is not less than 200m 2 / g, preferably 200-1000m 2 / g; the pore diameter is 0.53-0.56nm; the pore volume is not less than 0.1cm 3 / g, preferably 0.1-1cm 3 / g.

[0045] In the present invention, the molecular sieve prepared by the method has relatively high crystallinity, and the crystallinity is above 98%.

[0046] The third aspect of the present invention provides the application of the molecular sieve described in the second a...

Embodiment 1

[0053] (1) The hexamethylammonium bromide of 7.78g, the sodium metaaluminate of 3.28g, the sodium hydroxide of 6g are dissolved in the water of 540g to form a solution; The silica sol (concentration is 30wt%) of 200g, slowly under stirring Add slowly to the solution of the above system, and stir evenly to prepare molecular sieve precursor gel A, wherein SiO 2 :Al 2 o 3 :H 2 O:OH - : The molar ratio of hexamethylammonium bromide is 1:0.02:30:0.15:0.0215;

[0054] (2) The hexamethylammonium bromide of 6.34g, the sodium metaaluminate of 0.82g, the sodium hydroxide of 5.2g are dissolved in the water of 270g to form a solution; The silica sol (concentration is 30wt%) of 200g, under stirring Slowly add to the solution of the above system, and stir evenly to prepare molecular sieve precursor gel B, wherein SiO 2 :Al 2 o 3 :H 2 O:OH - : The molar ratio of hexamethylammonium bromide is 1:0.005:15:0.13:0.0175;

[0055] (3) Put the molecular sieve precursor gels A and B into di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com