Preparation methods of corrosion-resistant aluminum honeycomb core and aluminum honeycomb plates

An aluminum honeycomb, corrosion-resistant technology, used in chemical instruments and methods, heating methods, mechanical equipment, etc., can solve the problems affecting the life of the honeycomb core, oxidation, etc., to improve oxidation resistance and weather resistance, high strength, anti-oxidation good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

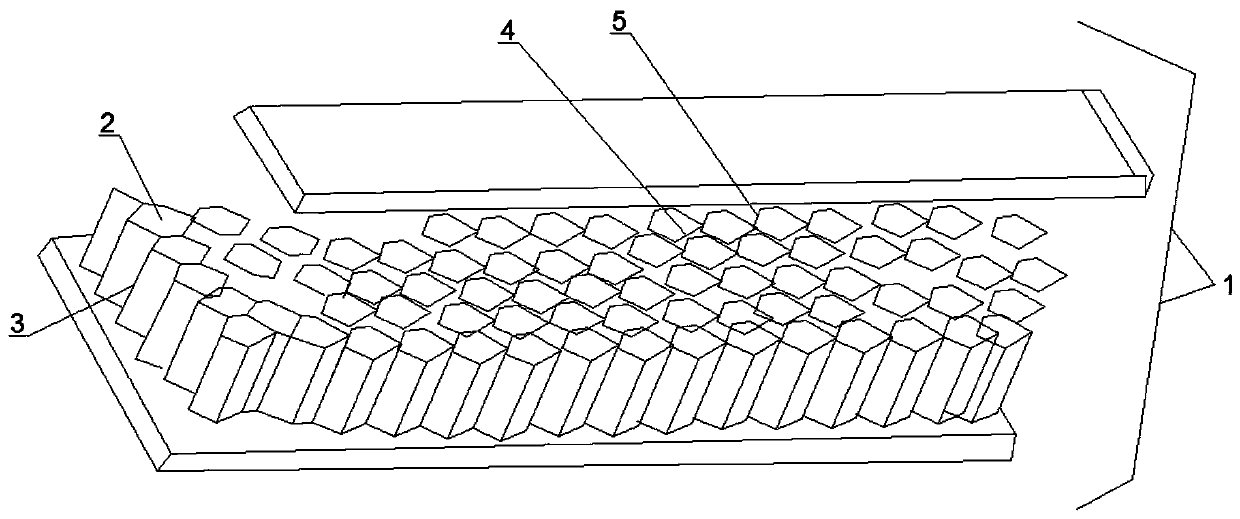

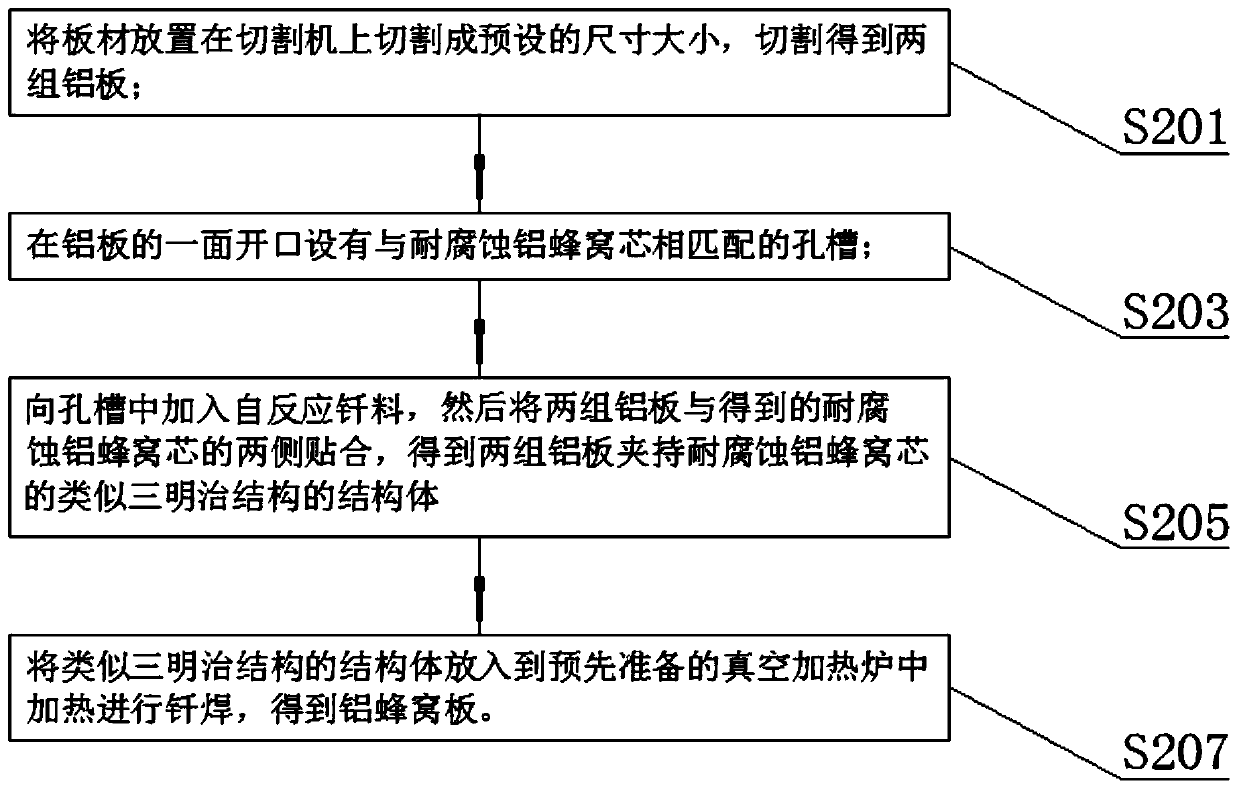

[0037] Such as Figure 1-3 As shown, the method for preparing a corrosion-resistant aluminum honeycomb core and aluminum honeycomb panel according to an embodiment of the present invention includes an aluminum honeycomb panel 1, which is characterized in that the aluminum honeycomb panel 1 is spliced to form a hexagonal channel 2, and the six The polygonal pores 2 are mutually formed to form a plate-shaped body 3, and the angle between the hexagonal pores 2 and the front surface of the plate-shaped body 3 is 5-20 degrees. The aluminum honeycomb panel 1 is coated with a formaldehyde removal coating Layer 4, the formaldehyde removal coating 4 is coated on the inner wall of the hexagonal channel 2, and the hexagonal channel 2 is located on the formaldehyde removal coating 4 and is coated with an anticorrosive and corrosion resistant layer 5, The anticorrosive and anticorrosive layer 5 is a mixture, wherein the components of the mixture include vinyl chloride, stabilizers, proces...

Embodiment 2

[0039] Such as Figure 1-3 As shown, the weight ratio of the vinyl chloride, the stabilizer, the processing modifier, the plasticizer, the SiC nanopowder and the corrosion resistant agent of the mixture ranges from 10.5-2: 0.5-2: 0.01-0.2: 0.2-0.8: 0.2-0.8: 0.5, the corrosion resistant agent is S-5373, the angle between the hexagonal channel 2 and the front surface of the plate-shaped body 3 in the vertical direction is 10- 12 degrees, the diameter of the circumscribed circle of the hexagonal channel 2 of the aluminum honeycomb panel 1 is 0.8-2.5 mm, and the thickness of the aluminum honeycomb panel is 0.9-2.1 cm.

Embodiment 3

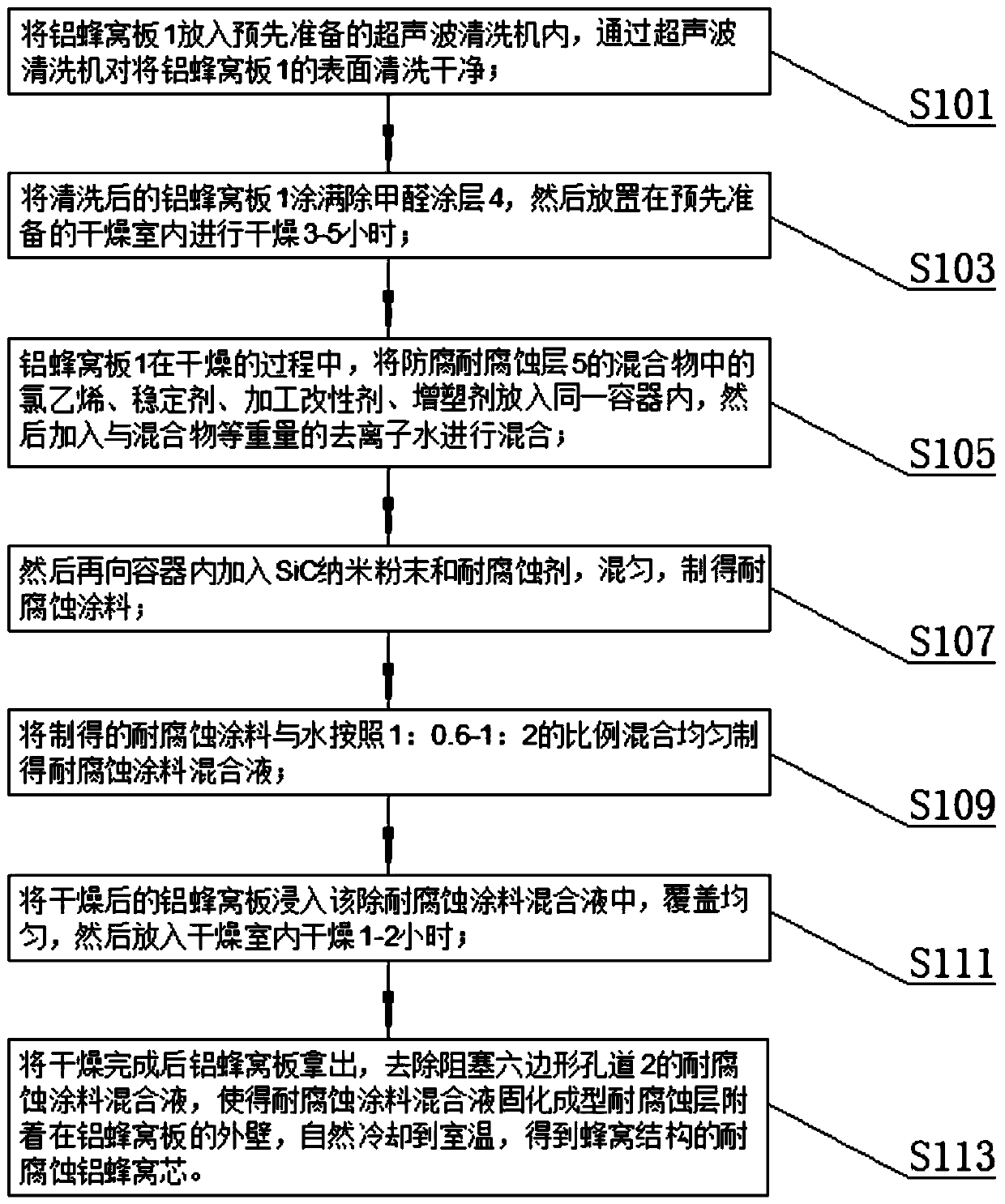

[0041] Such as Figure 1-3 As shown, according to another aspect of the present invention, a method for preparing a corrosion-resistant aluminum honeycomb core is provided. The method for preparing a corrosion-resistant aluminum honeycomb core includes the following steps:

[0042] Put the aluminum honeycomb panel 1 into the pre-prepared ultrasonic cleaning machine, and clean the surface of the aluminum honeycomb panel 1 through the ultrasonic cleaning machine;

[0043] Coat the cleaned aluminum honeycomb panel 1 with the formaldehyde removal coating 4, and then place it in the pre-prepared drying room for drying for 3-5 hours;

[0044] During the drying process of the aluminum honeycomb panel 1, put the vinyl chloride, stabilizer, processing modifier, and plasticizer in the mixture of the anticorrosive and anticorrosive layer 5 into the same container, and then add deionized water equal to the weight of the mixture Mix

[0045] Then add SiC nano-powder and corrosion-resistant agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com