Method for recovering platinum group metal from waste catalyst through melt extraction vacuum distillation

A technology of waste catalysts and platinum group metals, which is applied in the direction of improving process efficiency, can solve problems such as complex processes, and achieve the effects of shortened treatment process, simple process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

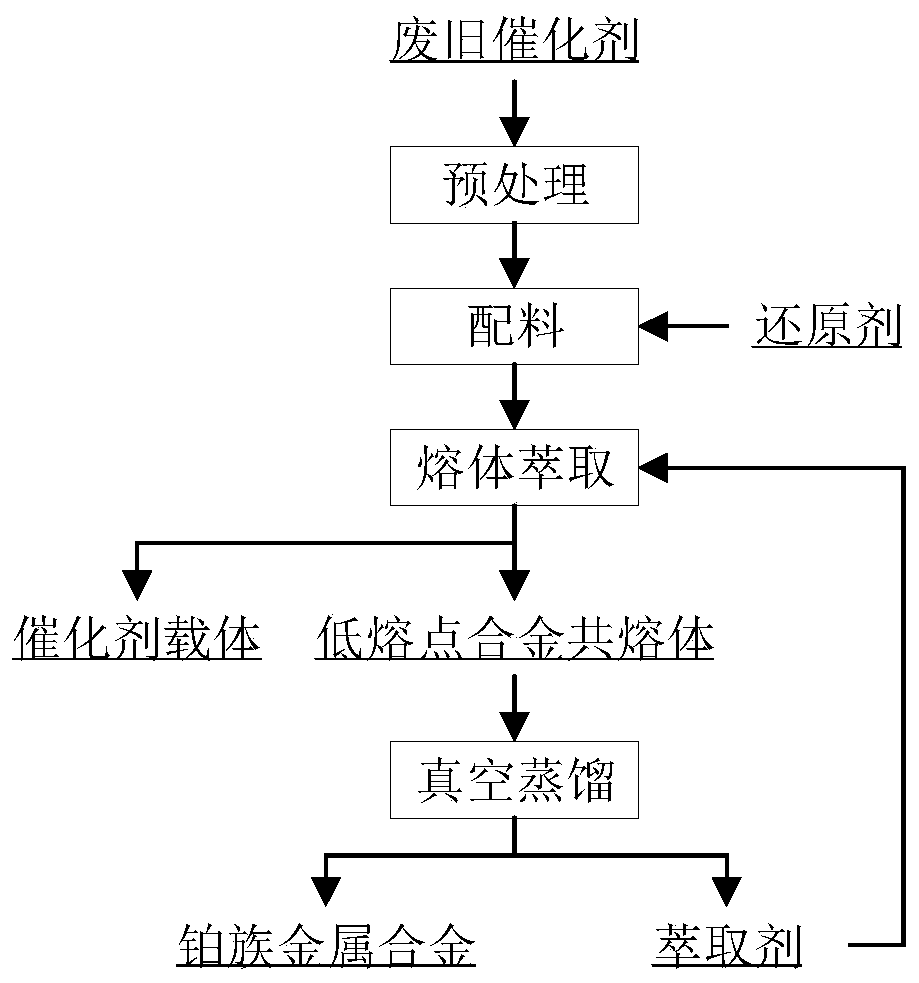

[0041] See attached figure 1According to the technical process, the waste automobile catalyst is crushed to about 15mm; take 2Kg of waste automobile scrap (including Pt 365g / t, Pd 1020g / t, Rh 220g / t), coke 0.1Kg and fully mix it with 10Kg metal Pb Place in a closed reaction furnace, heat up to 800°C to melt metal Pb for melt capture, and finally obtain an alloy eutectic rich in platinum group metals and a solid catalyst carrier. The two are divided into two types due to immiscibility and large difference in specific gravity. Two layers, the upper layer is a solid catalyst carrier, and the lower layer is an alloy eutectic; when the melt is cooled, the alloy will gradually solidify and separate from the catalyst carrier, put the alloy melt into a vacuum furnace, control the pressure in the furnace to 5Pa, and the temperature At 950°C, keep the temperature for 30 minutes to obtain Pb condensate and platinum group metal residues, and return the Pb condensate to the melt for extrac...

Embodiment 2

[0043] See attached figure 1 According to the technical process, the waste automobile catalyst is crushed to about 10mm; take 1Kg of waste automobile scrap (including Pt 370g / t, Pd 1100g / t, Rh 198g / t), coke 0.05Kg and fully mix it with 5Kg metal Sb Put it in a closed reaction furnace, raise the temperature to 1000°C to melt metal Sb for melt capture, and finally obtain an alloy eutectic rich in platinum group metals and a solid catalyst carrier. The two are divided into two types due to immiscibility and large difference in specific gravity. Two layers, the upper layer is a solid catalyst carrier, and the lower layer is an alloy eutectic; after cooling the melt, the alloy will gradually solidify and separate from the catalyst carrier, put the alloy melt into a vacuum furnace, control the pressure in the furnace to 10Pa, and the temperature The temperature is 950°C, and the temperature is kept constant for 60 minutes to obtain Sb condensate and platinum group metal residues, an...

Embodiment 3

[0045] See attached figure 1 According to the technical process, the waste automobile catalyst is crushed to about 20mm; take 2Kg of waste automobile scrap (including Pt 390g / t, Pd 1050g / t, Rh 210g / t), coke 0.1Kg and fully mix it with 10Kg metal Bi Put it in a closed reaction furnace, raise the temperature to 900°C to melt the metal Bi for melt capture, and finally obtain an alloy eutectic rich in platinum group metals and a solid catalyst carrier. The two are divided into two types due to immiscibility and large difference in specific gravity Two layers, the upper layer is a solid catalyst carrier, and the lower layer is an alloy eutectic; after cooling the melt, the alloy will gradually solidify and separate from the catalyst carrier, put the alloy melt into a vacuum furnace, control the pressure in the furnace to 15Pa, and the temperature At 1000°C, keep the temperature for 40 minutes to obtain Bi condensate and platinum group metal residues, and return the Bi condensate to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com