Polyformaldehyde fiber, modification method and application of polyformaldehyde fiber

A polyoxymethylene fiber modification technology, applied in fiber type, fiber treatment, ultrasonic/acoustic fiber treatment, etc., can solve the problems of weak interface bonding strength, complex process, limited fiber reinforcement effect, etc. The method is simple and improved Effects of interface strength, increased chemical reactivity, and roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) 0.2g nano-SiO 2 The powder is dispersed in 19.8g of aqueous medium, and 0.004g of γ-methacryloxypropyltrimethoxysilane coupling agent is added to nano-SiO at 70°C 2 The dispersion liquid was stirred for 2 hours to obtain a modified nano-silica powder dispersion liquid with a mass concentration of 1 wt%.

[0040] (2) The POM fiber is treated with a long and narrow linear dielectric barrier discharge plasma treatment device parallel to the fiber to be treated, that is, as Figure 4 As shown, the POM fibers are placed parallel to the electrodes, and the two ends of the fibers are respectively hung on the support frames of the two electrodes for processing. The processing atmosphere is air, the processing voltage is 220v, the processing power is 400w, and the processing time is 60s. The modified POM fiber with certain texture and active groups on the surface is obtained.

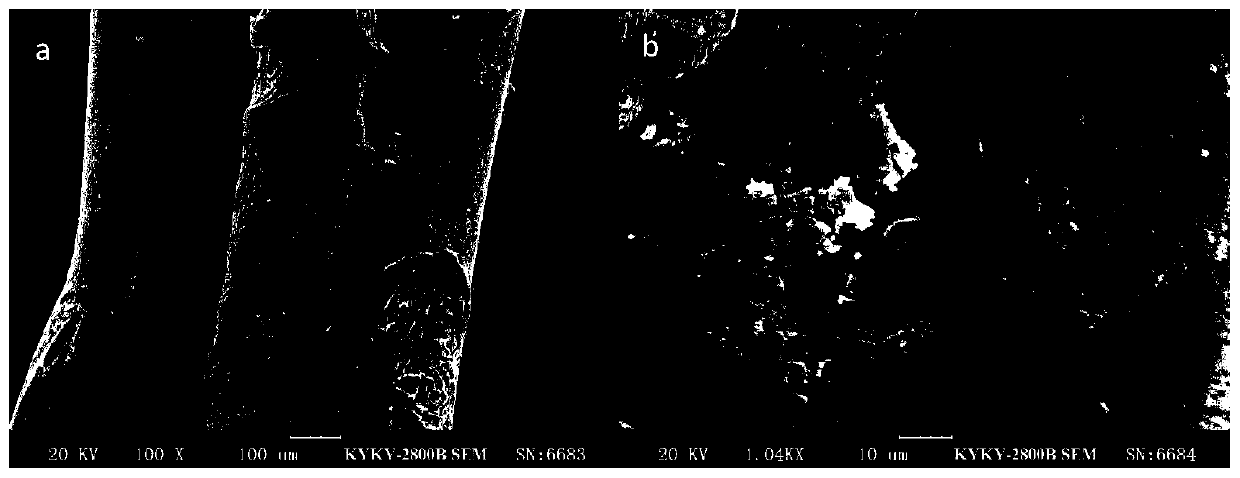

[0041] The scanning electron microscope pictures of POM fibers before and after modification are...

Embodiment 2

[0045] (1) 0.4g nano-SiO 2 The powder is dispersed in 19.6g of aqueous medium, and 0.004g of γ-methacryloxypropyltrimethoxysilane coupling agent is added to nano-SiO at 70°C 2 The dispersion liquid was stirred for 2 hours to obtain a modified nano-silica powder dispersion liquid with a mass concentration of 2 wt%.

[0046] (2) Adopt linear dielectric barrier discharge plasma processing device to process POM fiber, that is, place POM fiber parallel to the electrodes, and hang the two ends of the fiber on the support frames of the two electrodes respectively for processing. The processing atmosphere is air, and the processing The voltage was 220v, the processing power was 400w, and the processing time was 60s to obtain plasma-modified POM fibers. The modified POM fiber with certain texture and active groups on the surface was obtained, and the tensile performance test was carried out. The breaking strength of the original fiber was reduced from 26.50N to 10.23N.

[0047] (3) P...

Embodiment 3

[0050] (1) 0.6g nano-SiO 2 The powder is dispersed in 19.4g of aqueous medium, and 0.004g of γ-methacryloxypropyltrimethoxysilane coupling agent is added to nano-SiO at 70°C 2 The dispersion liquid was stirred for 2 hours to obtain a modified nano-silica powder dispersion liquid with a mass concentration of 3 wt%.

[0051] (2) Adopt linear dielectric barrier discharge plasma processing device to process POM fiber, that is, place POM fiber parallel to the electrodes, and hang the two ends of the fiber on the support frames of the two electrodes respectively for processing. The processing atmosphere is air, and the processing The voltage was 220v, the processing power was 400w, and the processing time was 60s to obtain plasma-modified POM fibers. The modified POM fiber with certain texture and active groups on the surface was obtained, and the tensile performance test was carried out. The breaking strength of the original fiber was reduced from 26.50N to 10.23N.

[0052] (3) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com