High-protein additive-free yoghourt and preparation method thereof

An additive-free, high-protein technology, applied in milk preparations, other dairy products, bacteria used in food preparation, etc., can solve problems such as low nutritional content, achieve high nutritional value, high protein and fat content, and rich taste. Kind of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

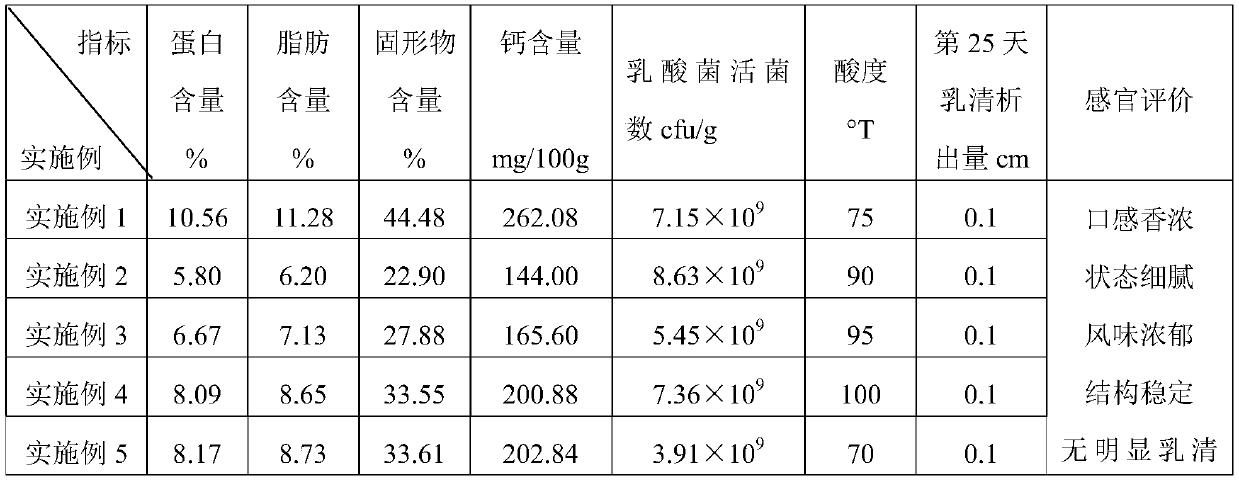

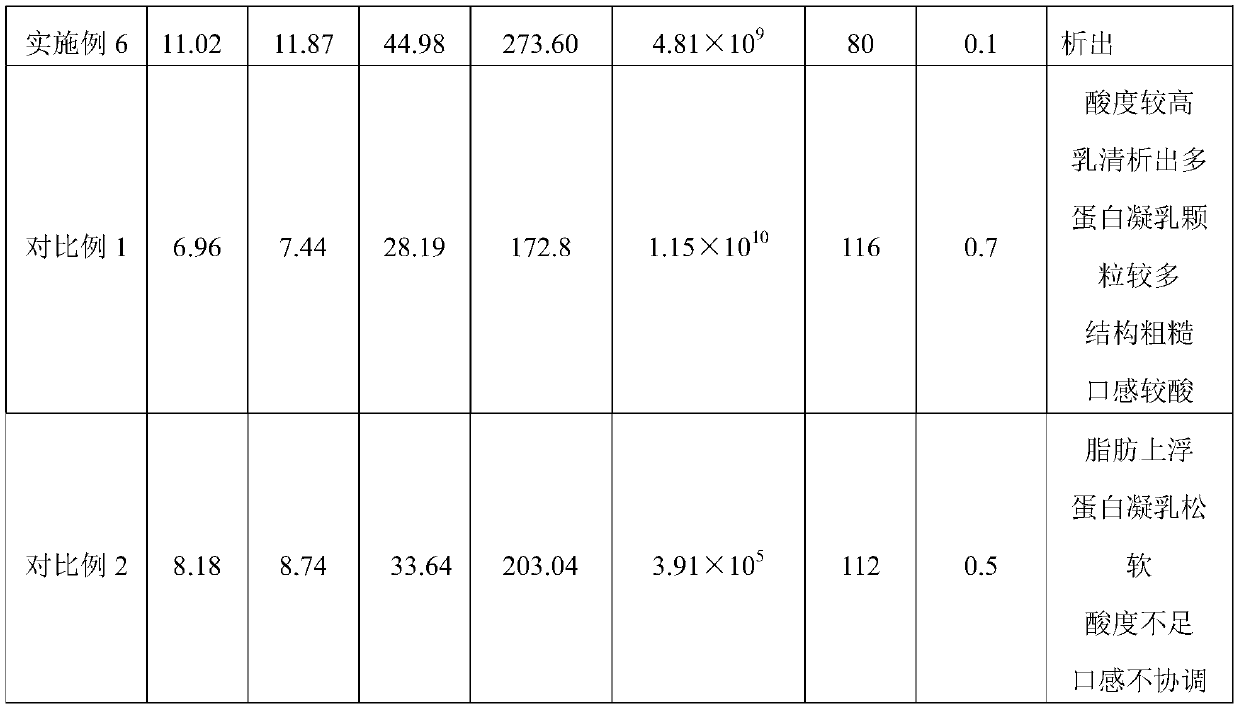

Examples

Embodiment 1

[0040] A high-protein yoghurt without additives, the formula of which comprises: raw milk, white sugar and fermented strains. Based on 1000 parts of raw materials, it includes the following components by mass. The content of raw milk is 910 parts, the content of white sugar is 90 parts, and the content of fermentation bacteria (Lactobacillus bulgaricus + Streptococcus thermophilus + Lactobacillus casei) is 200DCU.

[0041] The production method of the high-protein yoghurt without adding comprises the following steps:

[0042] (1) Preheat raw milk to 60°C, add white sugar and stir for 15 minutes, homogenize, sterilize, cool to 37°C, inoculate lactic acid bacteria starter (Lactobacillus bulgaricus + Streptococcus thermophilus + Lactobacillus casei) 200DCU, ferment Finally, the flavored yoghurt is prepared;

[0043] Among them, homogeneous conditions: temperature is 60°C, primary pressure is 5MPa, secondary pressure is 17MPa; sterilization conditions: temperature is 90°C, heat p...

Embodiment 2

[0047] A high-protein yoghurt without addition, the formula of which comprises raw milk and fermented strains. Based on 1000 parts of raw materials, it includes the following components by mass, the content of raw milk is 1000 parts, and the content of fermented bacteria (Lactobacillus bulgaricus+Lactococcus lactis subspecies cream fat) is 250DCU.

[0048] The production method of the high-protein yoghurt without adding comprises the following steps:

[0049] (1) Raw milk is preheated to 50°C, homogenized, sterilized, cooled to 38°C, inoculated with 250 DCU of lactic acid bacteria starter (Lactobacillus bulgaricus + Lactococcus lactis subsp. milkfat), and fermented to obtain flavored yogurt;

[0050] Among them, homogeneous conditions: temperature is 75°C, primary pressure is 3MPa, secondary pressure is 25MPa; sterilization conditions: temperature is 98°C, heat preservation for 5min; after sterilization, it is cooled to 38°C by plate cooler; fermentation conditions: temperatur...

Embodiment 3

[0054] A high-protein yoghurt without additives, the formula of which comprises: raw milk, white sugar and fermented strains. Based on 1000 parts of raw materials, including the following components by mass, the content of raw milk is 920 parts, the content of white sugar is 80 parts, and the content of fermentation bacteria (Lactobacillus bulgaricus + Streptococcus thermophilus + Lactobacillus acidophilus) is 300DCU .

[0055] The production method of the high-protein yoghurt without adding comprises the following steps:

[0056] (1) Preheat raw milk to 55°C, add white sugar and stir for 20 minutes, homogenize, sterilize, cool to 36°C, inoculate lactic acid bacteria starter (Lactobacillus bulgaricus + Streptococcus thermophilus + Lactobacillus acidophilus) 300DCU, Flavored yogurt is obtained after fermentation;

[0057] Among them, homogeneous conditions: temperature is 70°C, primary pressure is 4MPa, secondary pressure is 18MPa; sterilization conditions: temperature is 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com