Recovery method of sulfosalicylic acid and p-toluenesulfonic acid in doxycycline hydrogenation wastewater

A technology of sulfosalicylic acid and p-toluenesulfonic acid, which is applied in chemical instruments and methods, sulfonic acid preparation, sulfonate preparation, etc., can solve the problems of pollution, high investment and treatment costs, and low wastewater treatment rate. Achieve the effects of reducing production costs, reducing solid waste, and increasing biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

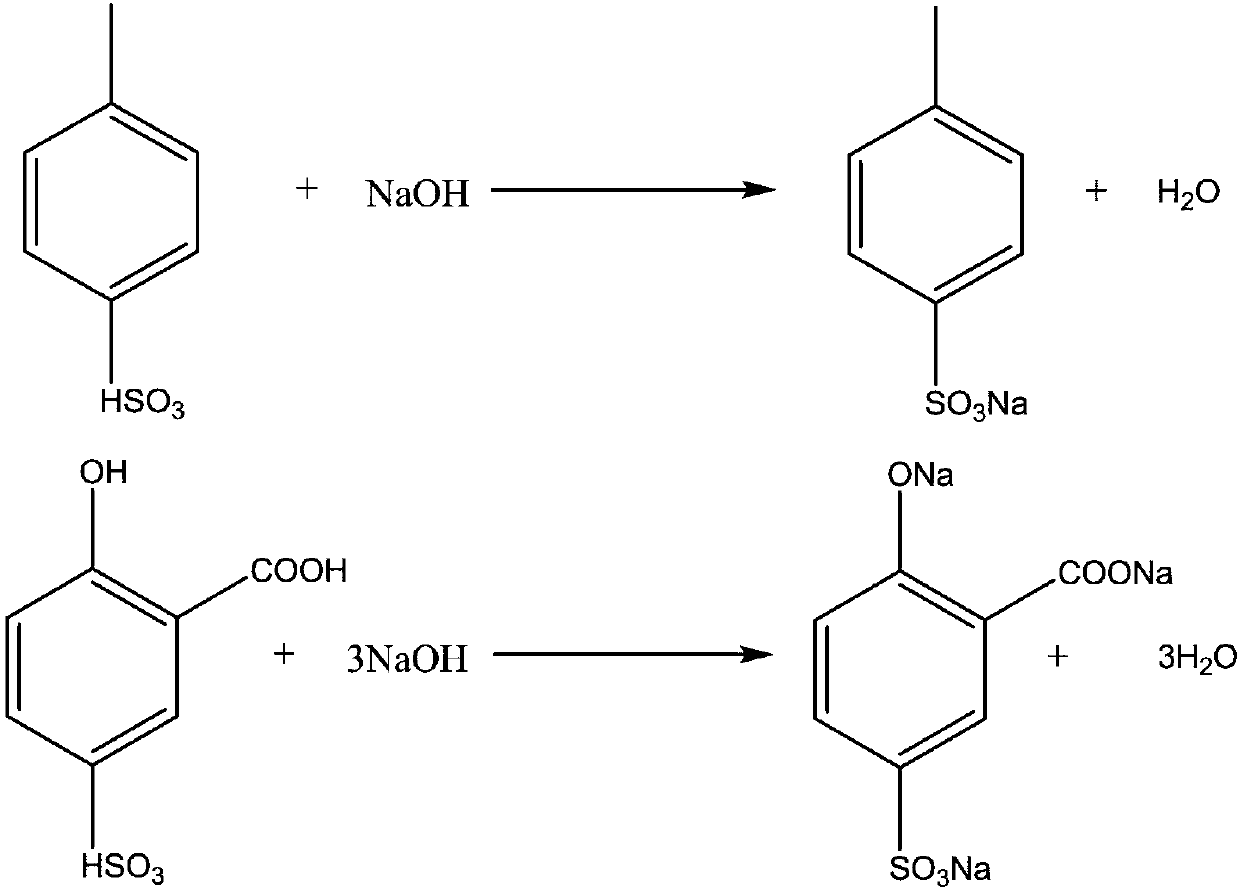

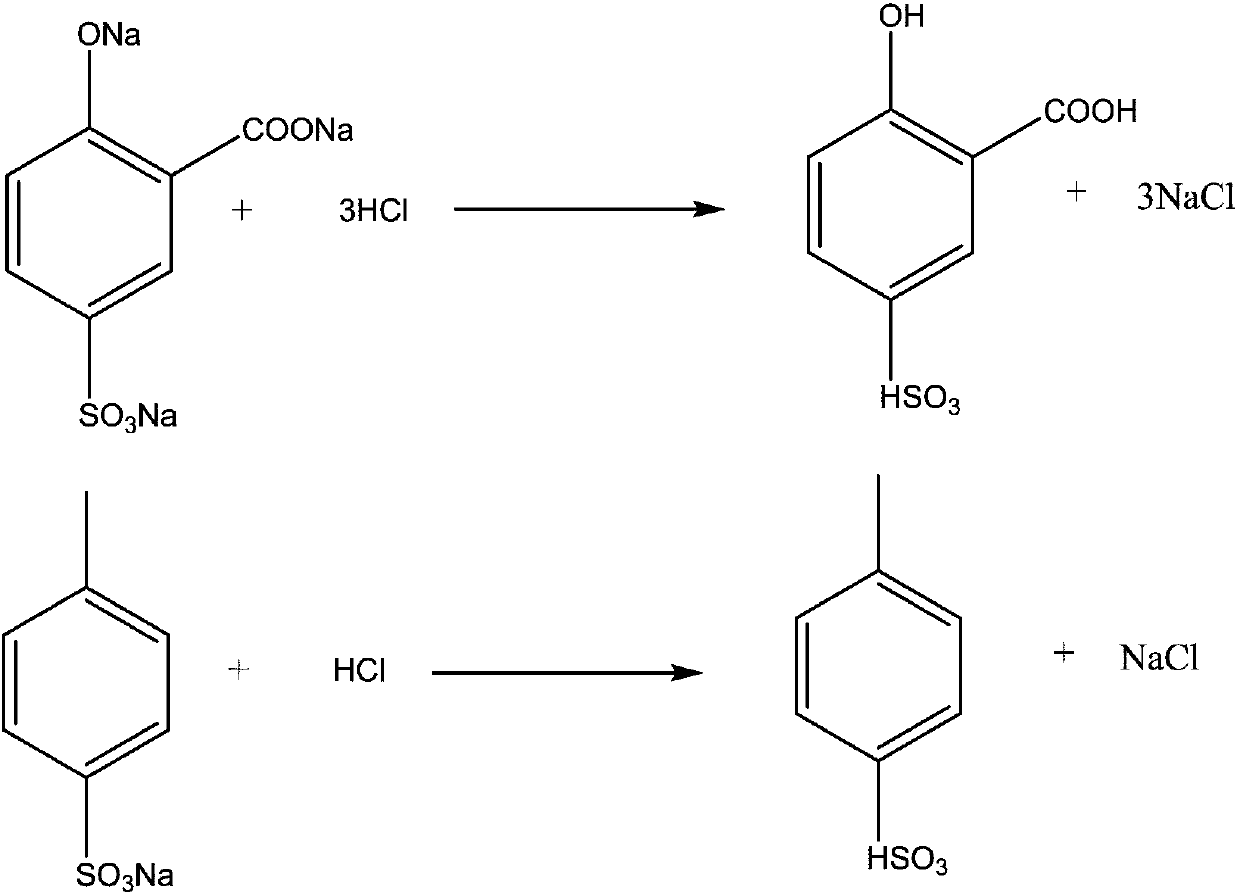

Image

Examples

Embodiment 1

[0036] The recovery method of sulfosalicylic acid and p-toluenesulfonic acid in doxycycline hydrogenation wastewater, the specific steps are:

[0037] S1. Neutralization reaction of doxycycline hydrogenation wastewater

[0038] Take doxycycline hydrogenation wastewater and heat it to 30°C, adjust the pH of doxycycline hydrogenation wastewater with 25% sodium hydroxide solution until the pH value of doxycycline hydrogenation wastewater is 6; The temperature of the hydrogenation wastewater is controlled at 30°C, and after stirring for 30 minutes, the solution is filtered to remove insoluble matter in the solution;

[0039] S2, rectification to remove ethanol

[0040] inject the solution prepared in step S1 into a rectification tower to rectify and recover ethanol until all the ethanol in the solution is removed, wherein the temperature at the top of the rectification tower is 95°C;

[0041] S3, secondary impurity removal

[0042] Take the solution prepared in step S2, control...

Embodiment 2

[0057] The recovery method of sulfosalicylic acid and p-toluenesulfonic acid in doxycycline hydrogenation wastewater, the specific steps are:

[0058] S1. Neutralization reaction of doxycycline hydrogenation wastewater

[0059] Take doxycycline hydrogenation wastewater and heat it to 35°C, adjust the pH of doxycycline hydrogenation wastewater with 30% sodium hydroxide solution until the pH value of doxycycline hydrogenation wastewater is 7; The temperature of the hydrogenation wastewater was controlled at 35°C, and after stirring for 450 minutes, the solution was filtered to remove insoluble matter in the solution;

[0060] S2, rectification to remove ethanol

[0061] inject the solution prepared in step S1 into a rectification tower to rectify and recover ethanol until all the ethanol in the solution is removed, wherein the temperature at the top of the rectification tower is 96°C;

[0062] S3, secondary impurity removal

[0063] Take the solution prepared in step S2, cont...

Embodiment 3

[0078] The recovery method of sulfosalicylic acid and p-toluenesulfonic acid in doxycycline hydrogenation wastewater, the specific steps are:

[0079] S1. Neutralization reaction of doxycycline hydrogenation wastewater

[0080] Take doxycycline hydrogenation wastewater and heat it to 40°C, adjust the pH of doxycycline hydrogenation wastewater with 35% sodium hydroxide solution until the pH value of doxycycline hydrogenation wastewater is 8; The temperature of the hydrogenation wastewater is controlled at 40°C, and after stirring for 1 hour, the solution is filtered to remove insoluble matter in the solution;

[0081] S2, rectification to remove ethanol

[0082] Inject the solution prepared in step S1 into a rectification tower to rectify and recover ethanol until all ethanol in the solution is removed, wherein the temperature at the top of the rectification tower is 98°C;

[0083] S3, secondary impurity removal

[0084] Take the solution prepared in step S2, control the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com