Foam material for bra

A technology of foam and bras, applied in applications, clothing, underwear, etc., can solve the problems of non-environmental protection in the production process, poor air permeability of PU foam materials, and women's health hazards, and achieve good antibacterial effect, not easy to grow and reproduce, easy to moisture wicking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

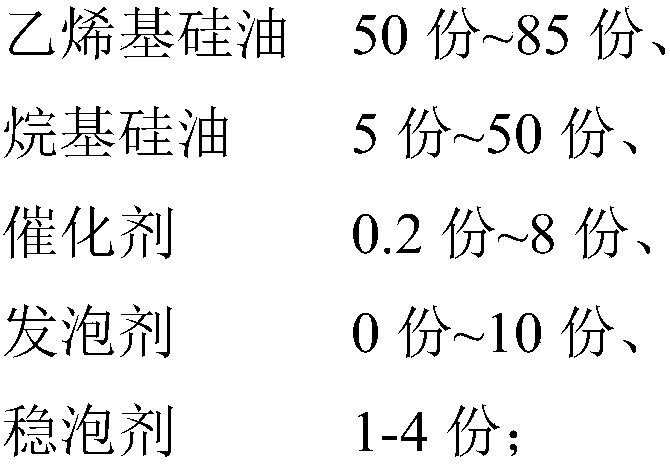

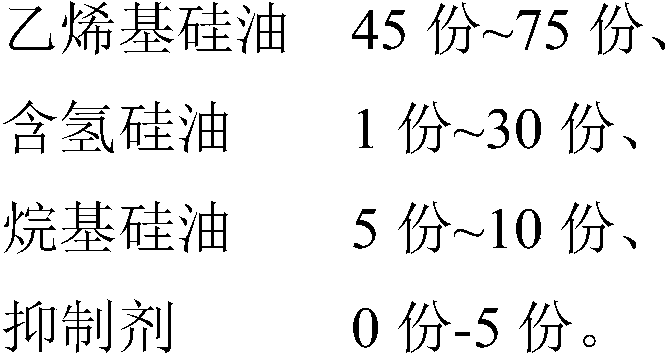

[0026] Embodiment 1. A foam material for brassiere, wherein the parts by weight of the components of raw material A are as follows: 50 parts of vinyl silicone oil, 25 parts of alkyl silicone oil, 0.2 parts of catalyst, 10 parts of foaming agent, 4 parts of foam stabilizer, 10 parts of functional filler; the parts by weight of each component of raw material B are as follows: 30 parts of hydrogen-containing silicone oil, 45 parts of vinyl silicone oil, 5 parts of alkyl silicone oil, 10 parts of functional filler, inhibitor 0.5 servings.

[0027] Keep raw material A and raw material B at a constant temperature of 25°C, put them into the batching bucket according to the mass ratio of 1:1, mix them evenly, inject them into the bra mold, seal and compress foam at room temperature for 1 hour, solidify and mold, and demould. This foam material is made following test and its result is as follows:

[0028] This foam material is made following test and its result is as follows:

[0029...

Embodiment 2

[0034] Embodiment 2. A foam material for bras. The parts by weight of each component of raw material A are as follows: 85 parts of vinyl silicone oil, 5 parts of alkyl silicone oil, 3 parts of catalyst, 8 parts of foaming agent, foam stabilizer 2 parts of agent; 8 parts of functional filler; the parts by weight of each component of raw material B are as follows: 1 part of hydrogen-containing silicone oil, 75 parts of vinyl silicone oil, 4.5 parts of functional filler, and 2 parts of inhibitor.

[0035] Keep raw material A and raw material B at a constant temperature of 25°C, put them into the batching bucket according to the mass ratio of 1:1, mix them evenly, pour them into the bra mold, and naturally foam at room temperature for 30 minutes to solidify and mold, and demould. This foam material is made following test and its result is as follows:

[0036] Density (g / cm 3 )0.32;

[0037] Hardness (shore FO) 30;

[0038] Porosity (%) 85;

[0039] Compression set rate (%) 3.0...

Embodiment 3

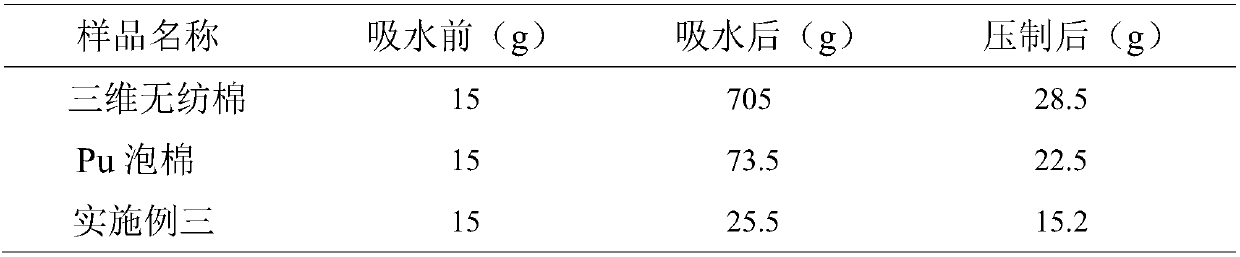

[0041] Embodiment 3, a kind of foam material for bra, wherein, the parts by weight of each component of raw material A are as follows: 70.5 parts of vinyl silicone oil, 10 parts of methyl silicone oil, 8 parts of catalyst, 10 parts of foaming agent, 2 parts of foam stabilizer, 8 parts of functional filler; the parts by weight of each component of raw material B are as follows: 20 parts of hydrogen-containing silicone oil, 60 parts of ethyl silicone oil, 10 parts of alkyl silicone oil, 4.5 parts of functional filler, inhibitor 5 servings.

[0042] Send raw material A and raw material B to the A glue channel and B glue channel of the glue injection machine respectively, start the glue injection machine, squeeze raw material A and raw material B into the mixer according to the mass ratio of 1:1, and stir. The speed is controlled at 3000rpm, and the stirring time is 10s. Then, inject the uniformly stirred colloid into the bra mold, and naturally foam at room temperature 25°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com