Catalyst for preparing cyclohexanone by phenol hydrogenation and preparation method thereof

A technology for catalyst and hydrogen preparation, which is applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc. It can solve the problems of easy loss of precious metals, poor cycle stability, high consumption of precious metals, etc., and achieve high catalytic intrinsic activity and low cost , the effect of uniform dispersion of metal particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of phenol hydrogenation prepares cyclohexanone catalyst and preparation method thereof, comprises the steps:

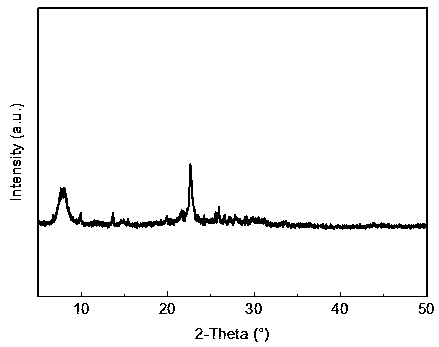

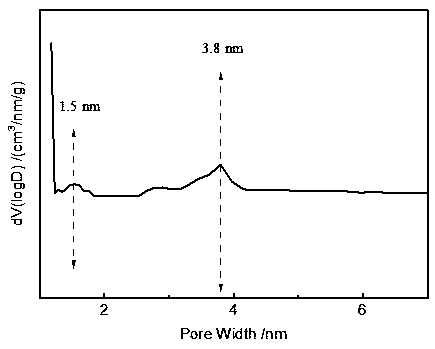

[0029] Preparation of the carrier: Under stirring conditions, weigh 15 g of industrial grade H-Beta molecular sieve, 500 g of concentrated nitric acid, and 150 g of distilled water, and mix them evenly. and ZrOCl 2 ·8H 2 O0.16 g and 15 g of distilled water were mixed evenly, mixed in a hydrothermal kettle at 80 °C for 24 h, filtered and dried with suction; the obtained product was roasted in an air atmosphere at 550 °C for 4 h to obtain a carrier.

[0030] Catalyst preparation:

[0031] 0.0168 g PdCl 2 Dissolve in hydrochloric acid solution, add 10 mL of distilled water; weigh 1 g of the above carrier in a 50 mL beaker, add 20 mL of distilled water. After the two were mixed evenly, they were stirred at room temperature for 2 h. Rotary steam at 50°C, then put it in a hydrogenation furnace for activation, the activation condition is: 10% H 2 / Ar, the...

Embodiment 2

[0034] A kind of phenol hydrogenation prepares cyclohexanone catalyst and preparation method thereof, comprises the steps:

[0035] Preparation of the carrier:

[0036] Under stirring conditions, weigh 15 g of industrial-grade H-Beta molecular sieve, 500 g of concentrated sulfuric acid, and 50 g of distilled water and mix evenly. Reflux for 15 h in an oil bath at 105°C and cool to room temperature to obtain the product; mix the above product with ZrOCl2 ·8H 2 O 0.16 g and 15 g of distilled water were mixed evenly, mixed in a hydrothermal kettle at 80 °C for 6 h, and the obtained product was calcined in an oxygen atmosphere at 550 °C for 4 h to obtain a carrier.

[0037] Catalyst preparation:

[0038] 0.0168 g PdCl 2 Dissolve in hydrochloric acid solution, add 10 mL of distilled water; weigh 1 g of the above carrier in a 50 mL beaker, add 20 mL of distilled water. After the two were mixed evenly, they were stirred at room temperature for 2 h. Rotary steam at 50°C, then put...

Embodiment 3

[0040] A kind of phenol hydrogenation prepares cyclohexanone catalyst and preparation method thereof, comprises the steps:

[0041] Preparation of the carrier:

[0042] Under the condition of stirring, 15 g of industrial-grade H-Beta molecular sieves, 500 g of concentrated sulfuric acid, and 150 g of distilled water were mixed evenly. Reflux for 15 h in an oil bath at 105°C and cool to room temperature to obtain the product; mix the above product with ZrOCl 2 ·8H 2 O 0.16 g and 15 g of distilled water were mixed evenly, treated in a hydrothermal kettle at 180°C for 24 h, filtered and dried by suction; the obtained product was roasted at 550°C for 4 h in a nitrogen atmosphere to obtain a carrier.

[0043] Catalyst preparation:

[0044] 0.0168 g PdCl 2 Dissolve in hydrochloric acid solution, add 20 mL of distilled water; weigh 1 g of the above carrier in a 50 mL beaker, add 20 mL of distilled water. After the two were mixed evenly, they were stirred at room temperature for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com