Conductive resin binder grinding wheel and preparation technology thereof

A bonding agent and grinding wheel technology, which is applied in the direction of bonding grinding wheels, manufacturing tools, metal processing equipment, etc., can solve the problems of high grinding processing costs, difficult to solve high-precision processing of workpieces, poor repair dimensional accuracy, etc., to achieve good grinding Sharpened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

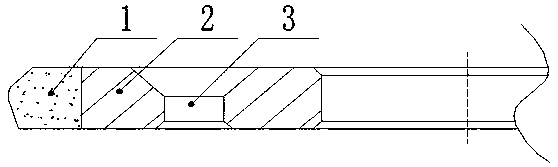

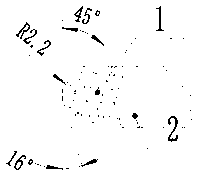

Image

Examples

Embodiment 1 to 4

[0032] Embodiments 1 to 4 preferably adopt the following raw materials:

[0033] PF-2893A phenolic resin (15-35μm) purchased by Shandong Shengquan Group Co., Ltd.;

[0034] ABN660 type CBN abrasive (200 / 230) purchased by British De Beers company;

[0035] Ultrafine cobalt powder (average 2μm) purchased from Eurotungstene, France;

[0036] Baige Group Co., Ltd. purchased white corundum powder (W5);

[0037] The silane coupling agent (A171) purchased by Fangzhou (Fogang) Chemical Materials Co., Ltd.

[0038] Embodiments 1 to 4 all adopt the following grinding wheel manufacturing process, and the concrete steps are as follows:

[0039] (1) Mix the silane coupling agent with methanol at a weight ratio of 1:20 and keep stirring evenly at 70°C to make a wetting agent;

[0040] (2) Mix the CBN abrasive and the wetting agent prepared in step (1) evenly in a weight ratio of 100:1, and then dry at 70°C to constant weight;

[0041](3) Mix the cobalt powder and the wetting agent prep...

Embodiment 1

[0055] The raw material ratio is as follows: phenolic resin powder 50g, ABN660 abrasive 14g, superfine cobalt powder 19g, white corundum micropowder 14g, coupling agent 3g; using the above process to prepare a conductive resin bond grinding wheel, after testing, Grinding wheel resistivity 3.22×10 6 Ω·cm, the accuracy of the special-shaped arc is 0.100mm, and the workpiece is burned and the wear resistance is poor during grinding.

Embodiment 2

[0057] 13 g of phenolic resin powder, 40 g of ABN660 abrasive, 22 g of superfine cobalt powder, 20 g of white corundum micropowder, and 5 g of coupling agent; the conductive resin bond grinding wheel was prepared by the above process, and the resistivity of the grinding wheel was 1.86 after testing. ×10 5 Ω·cm, the accuracy of the special-shaped arc is 0.069mm, the grinding wheel has good sharpness during grinding, and occasionally the structure of the grinding wheel peels off, etc., and the wear resistance is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com