Bionic structure monolithic catalyst preparing method based on 3D printing technology

A 3D printing, monolithic technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low conversion rate of reactants, lack of radial mass transfer, contact, etc., to achieve operational Less energy consumption, excellent mechanical properties, and the effect of improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) A piece of cancellous bone was cut from the end of bovine tibia, soaked in trichlorethylene for 48 hours, ultrasonicated for 30 minutes, and degreased to prepare a cancellous bone sample.

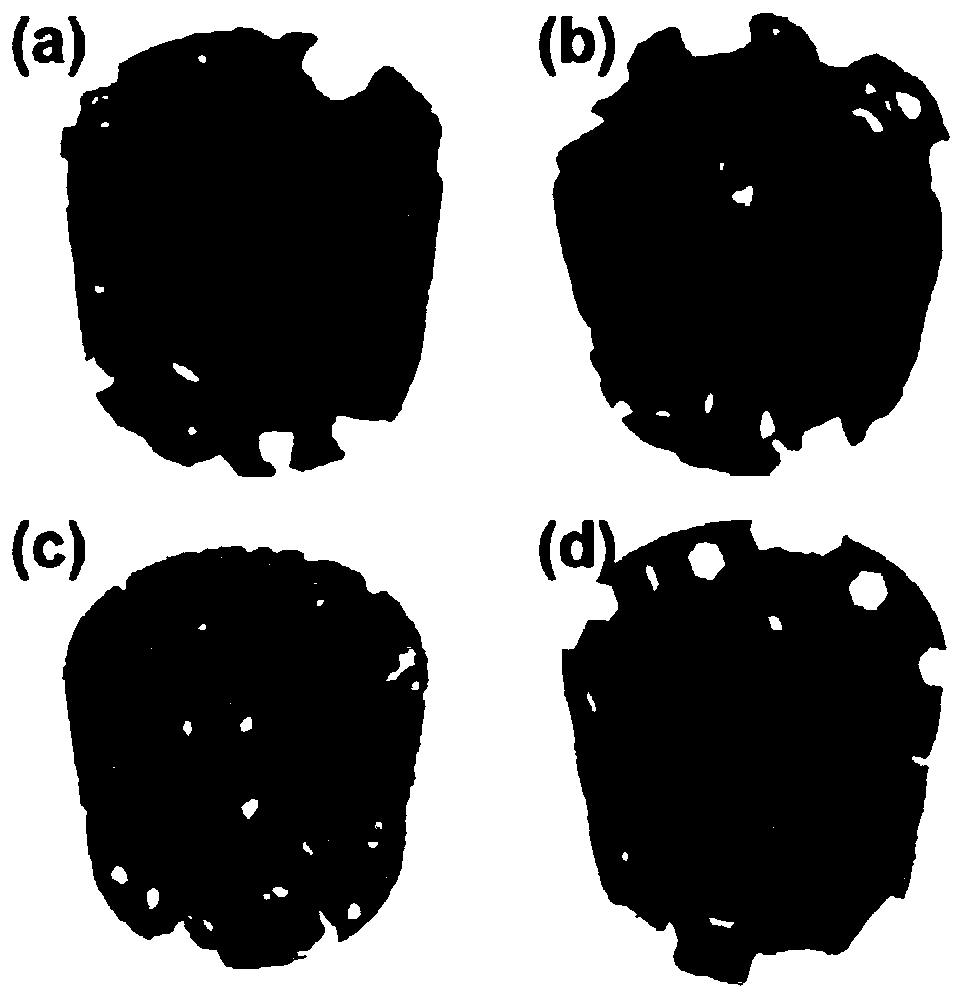

[0024] (2) Perform Micro-CT scanning on the cancellous bone sample obtained in step (1) to obtain a series of Micro-CT images of cancellous bone, and reconstruct the Micro-CT images to obtain a three-dimensional digital model of cancellous bone in STL format (See figure 1 Figure (a) in).

[0025] (3) The three-dimensional digital model of bovine tibial cancellous bone obtained in step (2) was 3D printed by means of fused deposition 3D printing, and the printing consumable was polylactic acid to prepare a monolithic catalyst with a biomimetic structure.

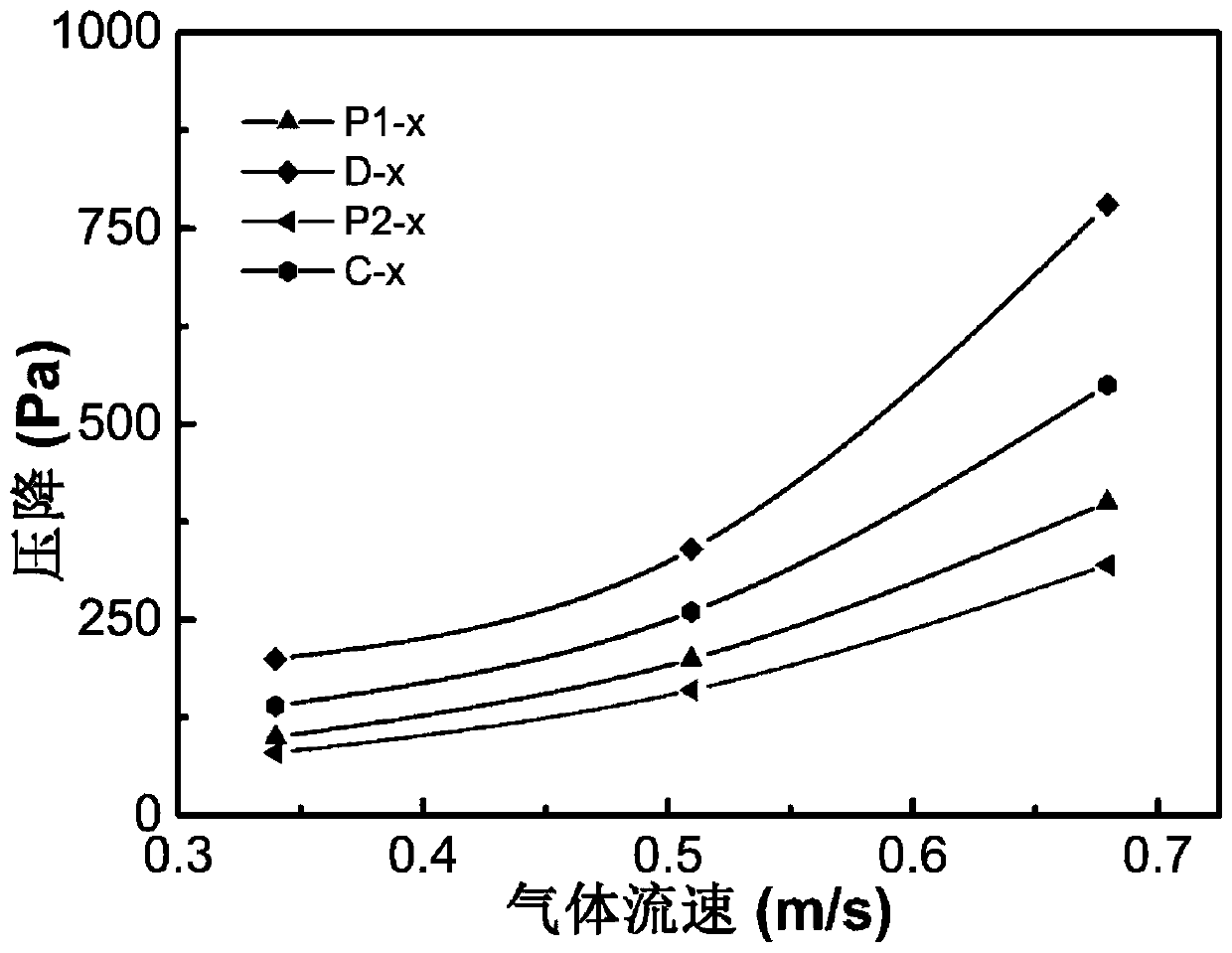

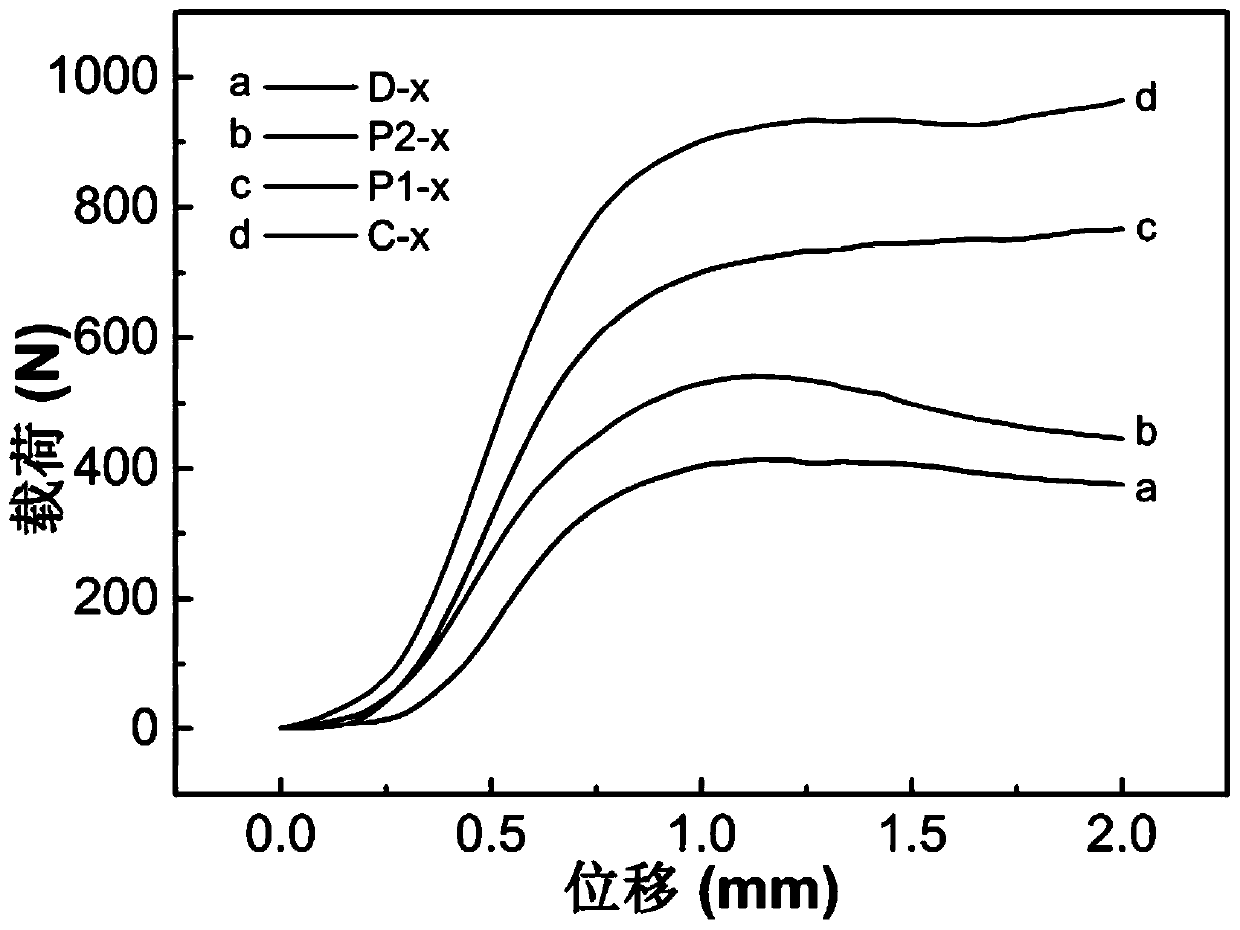

[0026] (4) Evaluation of pressure drop performance: The evaluation of pressure drop is carried out in an atmospheric quartz tube reactor, and the pressure measuring device is a U-shaped tube differential pressure gauge, and the ...

Embodiment 2

[0029] (1) A piece of cancellous bone was cut from the end of porcine femur, soaked in trichlorethylene for 60 hours, ultrasonicated for 20 minutes, and degreased to prepare a cancellous bone sample.

[0030] (2) Perform Micro-CT scanning on the cancellous bone sample obtained in step (1) to obtain a series of Micro-CT images of cancellous bone, and reconstruct the Micro-CT images to obtain a three-dimensional digital model of cancellous bone in STL format (See figure 1 (b) in Figure).

[0031] (3) The three-dimensional digital model of porcine femoral cancellous bone obtained in step (2) was 3D printed by means of fused deposition 3D printing. The printing consumable was polylactic acid, and a monolithic catalyst with a biomimetic structure was prepared.

[0032] (4) Pressure drop performance evaluation: according to the evaluation method of Example 1.

[0033] (5) Evaluation of mechanical properties: according to the evaluation method of Example 1.

Embodiment 3

[0035] (1) A piece of cancellous bone was cut from the end of pig lumbar vertebrae, soaked in trichlorethylene for 72 hours, ultrasonicated for 10 minutes, and degreased to prepare a cancellous bone sample.

[0036] (2) Perform Micro-CT scanning on the cancellous bone sample obtained in step (1) to obtain a series of Micro-CT images of cancellous bone, and reconstruct the Micro-CT images to obtain a three-dimensional digital model of cancellous bone in STL format (See figure 1 (c) in Figure).

[0037] (3) The three-dimensional digital model of porcine lumbar cancellous bone obtained in step (2) was 3D printed by means of fused deposition 3D printing. The printing consumable was polylactic acid, and a monolithic catalyst with a biomimetic structure was prepared.

[0038] (4) Pressure drop performance evaluation: according to the evaluation method of Example 1.

[0039] (5) Evaluation of mechanical properties: according to the evaluation method of Example 1.

[0040] In the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com