Drawer type tray feeding machine

A feeder and drawer-type technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of difficult estimation of maintenance costs, inability to meet space requirements, large volume, and large floor area. Achieve the effect of saving manual feeding cost, simple structure and avoiding frequent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

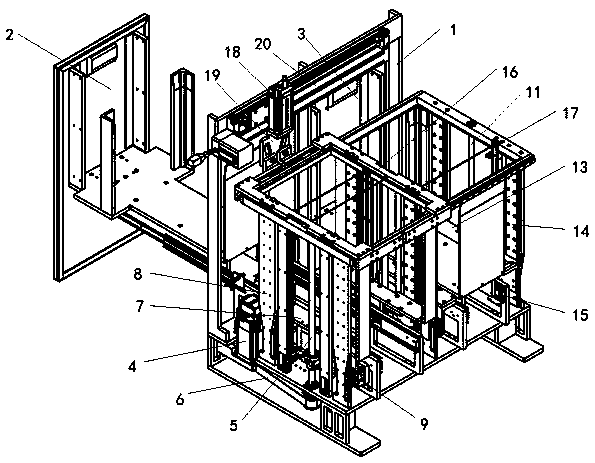

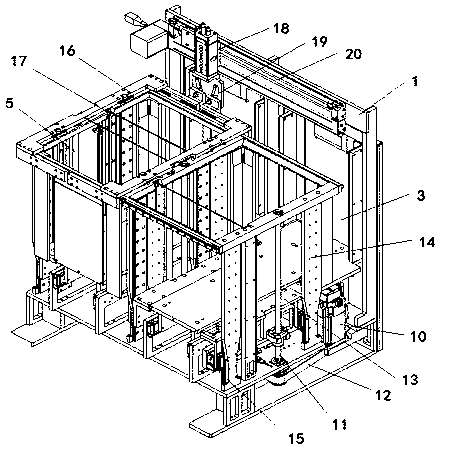

[0026] The invention discloses a drawer-type tray feeder and a corresponding feeding method thereof, specifically as follows.

[0027] Such as Figure 1~Figure 2As shown, a drawer-type tray feeder is matched with the loading and unloading mechanism set on the main platform of the production line, and includes a device frame 1, and a loading station and a feeding station are arranged side by side in the device frame 1 , and also includes various functional components arranged on the device frame 1, the functional components include a feeding drawer 2 for feeding materials into the feeding station, a feeding drawer 2 for driving the material tray in the feeding station to move vertically The servo lifting assembly, the tray traverse assembly used to drive the material tray to move horizontally from the side of the loading station to the side of the unloading station, the unloading servo lifting assembly used to drive the vertical movement of the material tray in the unloading st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com