High-stability mobile phone coating solution and preparation method thereof

A high-stability coating solution technology, applied in the manufacturing field, can solve problems such as surface dry time, unsatisfactory flatness, inability to withstand long-term harsh environments, poor film-forming performance and resistance to electrical corrosion, etc., to improve the ability of electrical corrosion resistance , Reduce energy consumption, short dry time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The raw materials for preparing the modified silicone resin in the present invention include alkoxysilane and fluoroalkylsilane.

[0024] In one embodiment, the alkoxysilane is selected from triethoxypentylsilane (CAS: 2761-24-2), propyltrimethoxysilane (CAS: 1067-25-0), butyl One or more combinations of trimethoxysilane (CAS: 1067-57-8), dimethoxydimethylsilane (CAS: 1112-39-6); the fluoroalkylsilane is selected from twelve Fluoroheptylpropylmethyldimethoxysilane (CAS: 1374604-19-9), Dodecafluoroheptylpropyltrimethoxysilane (CAS: 1105578-57-1), Perfluorooctyltrimethoxy One or several combinations of silanes (CAS: 85857-16-5).

[0025] In a preferred embodiment, the alkoxysilane is triethoxypentylsilane; the fluoroalkylsilane is dodecafluoroheptylpropylmethyldimethoxysilane.

[0026] In a more preferred embodiment, the molar ratio of the alkoxysilane to the fluoroalkylsilane is 1: (1.5-3); preferably, the molar ratio of the alkoxysilane to the fluoroalkylsilane It is...

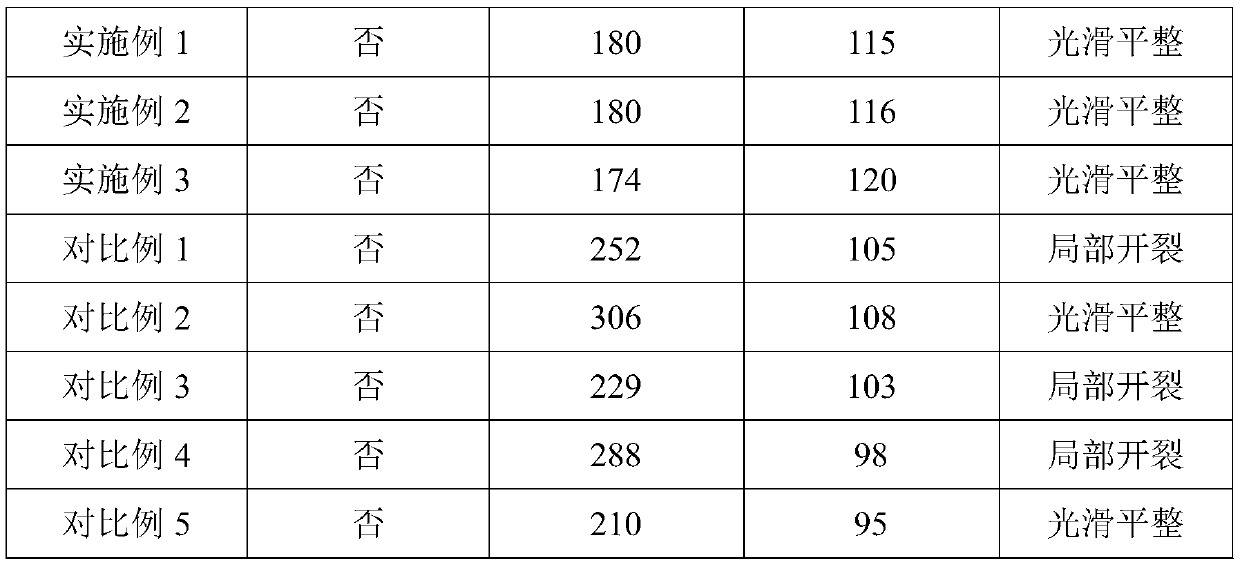

Embodiment 1

[0049] Embodiment 1 of the present invention provides a kind of high-stability mobile phone coating liquid, and by weight, preparation raw material comprises: 1.5 parts of modified silicone resins, 0.005 parts of catalysts, 95 parts of organic solvents, 0.05 parts of surfactants; The preparation raw materials also include vegetable oils.

[0050] The raw materials for the preparation of the modified silicone resin include alkoxysilane and fluoroalkylsilane; the alkoxysilane is triethoxypentylsilane; the fluoroalkylsilane is dodecafluoroheptylpropyl Methyldimethoxysilane; the molar ratio of the alkoxysilane to fluoroalkylsilane is 1:1.5.

[0051] The steps of the preparation method of the modified silicone resin are as follows: add triethoxypentylsilane and absolute ethanol into a three-necked flask, adjust the pH to 10 with ammonia water, vacuumize, heat to 90°C, react for 1 hour, and observe The viscosity of the reaction solution increases, then slowly add dodecafluoroheptyl...

Embodiment 2

[0058] Embodiment 2 of the present invention provides a kind of high-stability mobile phone coating liquid, and by weight, preparation raw material comprises: modified silicone resin 2 parts, catalyst 0.02 part, organic solvent 100 parts, surfactant 0.2 part; The preparation raw materials also include vegetable oils.

[0059] The raw materials for the preparation of the modified silicone resin include alkoxysilane and fluoroalkylsilane; the alkoxysilane is triethoxypentylsilane; the fluoroalkylsilane is dodecafluoroheptylpropyl Methyldimethoxysilane; the molar ratio of the alkoxysilane to fluoroalkylsilane is 1:3.

[0060] The steps of the preparation method of the modified silicone resin are as in Example 1.

[0061] The catalyst is dibutyltin dilaurate.

[0062] The organic solvent includes 165# alkane solvent oil and 90# alkane solvent oil; the mass ratio of the 165# alkane solvent oil to 90# alkane solvent oil is 1:3.

[0063] The surfactant is lauric acid.

[0064] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com