Leather shoe processing method capable of inhibiting growth and reproduction of mould

A processing method and technology for leather shoes, which are applied in leather surface treatment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc., can solve the problem that the antifungal agent increases the maintenance cost of leather shoes , Affect the use value and comfort, increase the degree of mildew and other problems, to achieve the effect of ensuring physical and mechanical strength, realizing economic and environmental benefits, and good cortex applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

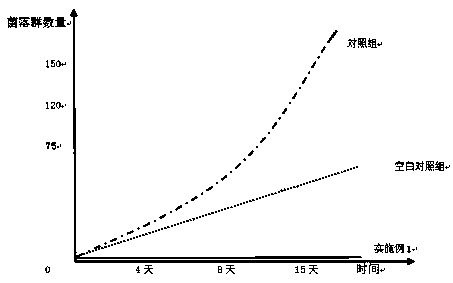

Image

Examples

Embodiment 1

[0015] A method for processing leather shoes that inhibits the growth and reproduction of mold, the preferred scheme is that during the process of leather shoe processing, the prepared anti-mold slurry is used to form a film on the leather leather material, and the graphene base contained in the film layer Metal skeleton composite nanomaterials have a strong killing effect on various molds;

[0016] Specifically, the following steps are included:

[0017] S1: Preparation of graphene-based metal skeleton composite nanomaterials: Weigh 7.0 grams of sodium carbonate and add it to a beaker, add 140 grams of deionized water to the beaker, stir and dilute to obtain an aqueous solution, add 1.2 grams of graphene to the sodium carbonate aqueous solution, Ultrasonic dispersion was performed for 15 minutes to obtain a stable suspension. Under continuous stirring, 3.5 milliliters of calcium chloride solution and 2.4 milliliters of cobalt chloride solution were successively added dropwise...

Embodiment 2

[0021] A method for processing leather shoes that inhibits the growth and reproduction of mold, the preferred scheme is that during the process of leather shoe processing, the prepared anti-mold slurry is used to form a film on the leather leather material, and the graphene base contained in the film layer Metal skeleton composite nanomaterials have a strong killing effect on various molds;

[0022] Specifically, the following steps are included:

[0023] S1: Preparation of graphene-based metal skeleton composite nanomaterials: Weigh 7.2 grams of sodium carbonate and add it to a beaker, add 145 grams of deionized water to the beaker, stir and dilute to obtain an aqueous solution, add 1.25 grams of graphene to the sodium carbonate aqueous solution, Ultrasonic dispersion was performed for 18 minutes to obtain a stable suspension. Under continuous stirring, 3.8 milliliters of calcium chloride solution and 2.6 milliliters of cobalt chloride solution were successively added dropwis...

Embodiment 3

[0027] A method for processing leather shoes that inhibits the growth and reproduction of mold, the preferred scheme is that during the process of leather shoe processing, the prepared anti-mold slurry is used to form a film on the leather leather material, and the graphene base contained in the film layer Metal skeleton composite nanomaterials have a strong killing effect on various molds;

[0028] Specifically, the following steps are included:

[0029] S1: Preparation of graphene-based metal skeleton composite nanomaterials: Weigh 7.5 grams of sodium carbonate and add it to a beaker, add 150 grams of deionized water to the beaker, stir and dilute to obtain an aqueous solution, add 1.3 grams of graphene to the sodium carbonate aqueous solution, Ultrasonic disperse for 20 minutes to obtain a stable suspension. Under continuous stirring, add 4.0 milliliters of calcium chloride solution and 2.8 milliliters of cobalt chloride solution to the suspension successively. The molar co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com