Resonant current sensor for PCB current measurement

A current sensor and current measurement technology, which is applied in the field of sensors, can solve the problems of high measurement accuracy of fluxgate current sensors, low accuracy of Hall current sensors, and influence on sensor accuracy, so as to save signal processing circuits, suppress temperature drift, Strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

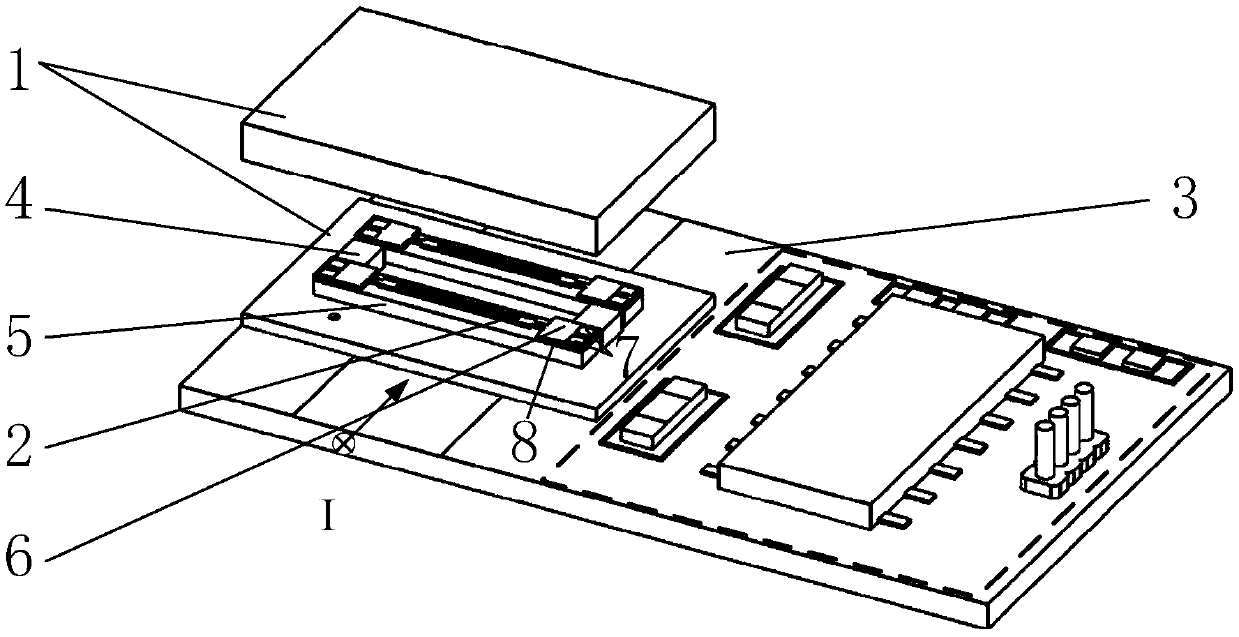

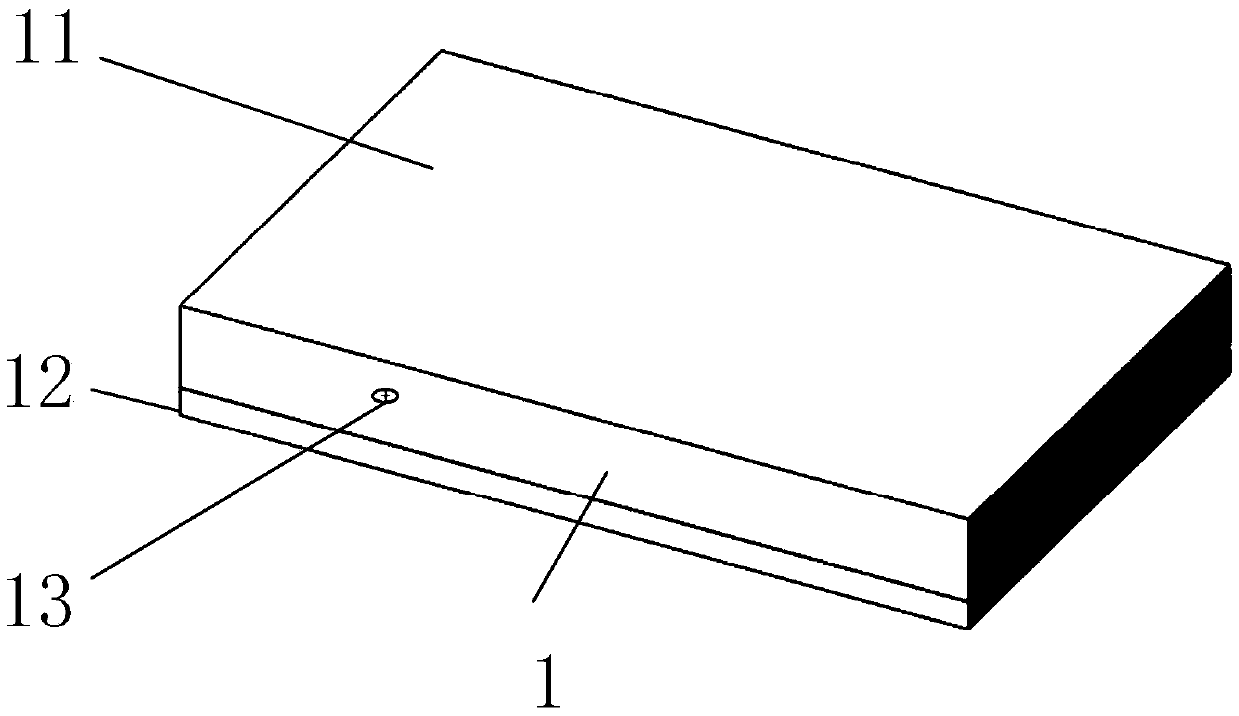

[0045] Such as figure 1 As shown, a resonant current sensor for PCB current measurement includes a resonant current sensing unit 6, a permanent magnet 4, a ceramic vacuum package shell 1, and a PCB board 3, wherein the resonant current sensing unit includes a magnetostrictive Unit 5, 2 quartz spacers 8, 1 quartz resonator 2. A current-carrying copper trace, an oscillating circuit, and an XOR frequency mixing circuit are laid on the PCB, and the current-sensitive unit 6 and the permanent magnet 4 are directly attached to the surface of the PCB current-carrying copper trace through the substrate.

[0046] The quartz resonator 2 is a double-beam quartz tuning fork fixed at both ends, and there are driving electrodes 7 at both ends of the tuning fork for connecting to an external oscillating circuit. The quartz resonator 2 works in a bending vibration mode, and the vibration directions of the two beams are symmetrical and opposite.

[0047] Quartz spacer 8 is as the transmission...

Embodiment 2

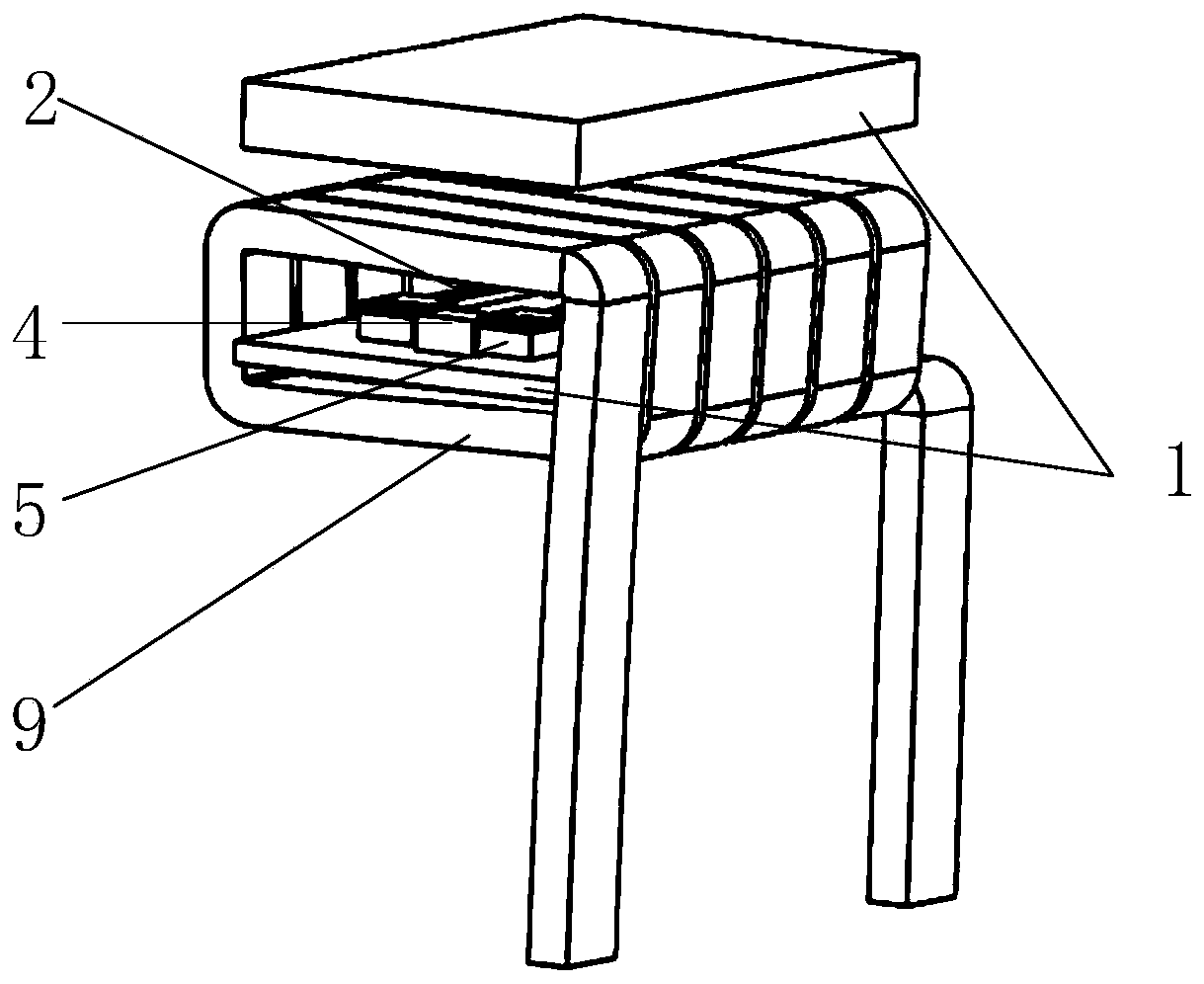

[0061] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the current to be measured flows through the rectangular coil 9 in this embodiment, that is, the resonant current sensitive unit and the permanent magnet are packaged in the ceramic shell 1, and the rectangular coil 9 is wound on around the housing 1 while the coil pins are connected to the onboard copper traces.

[0062] Preferably, the double-ended fixed tuning fork resonator 2 in this embodiment is the same as that in Embodiment 1.

[0063] In addition to the advantages described in Example 1, Example 2 also has the advantage of increased sensitivity compared to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com