A kind of solid electrolyte that can be used for lithium metal battery and preparation method thereof

A lithium metal battery and electrolyte technology, applied in the field of electrolytes, can solve the problems that fillers reduce the cycle stability of lithium metal batteries, cannot meet the needs of fast charging and fast discharging of lithium metal batteries, and reduce the cycle stability of batteries, etc., to achieve good thermodynamic stability and Effects of electrochemical stability, enhanced conduction and interfacial stability, and wide electrochemical stability window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

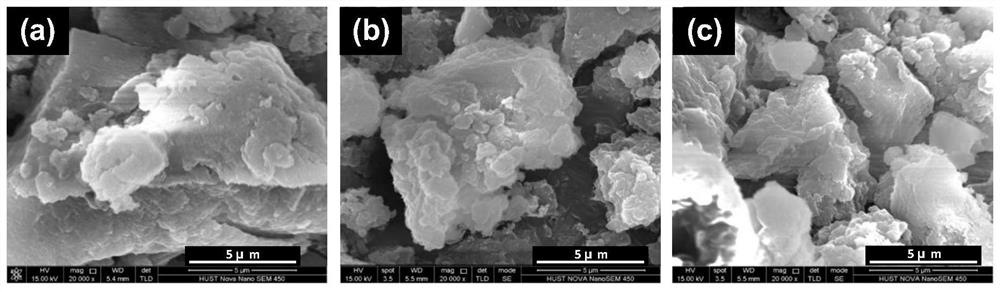

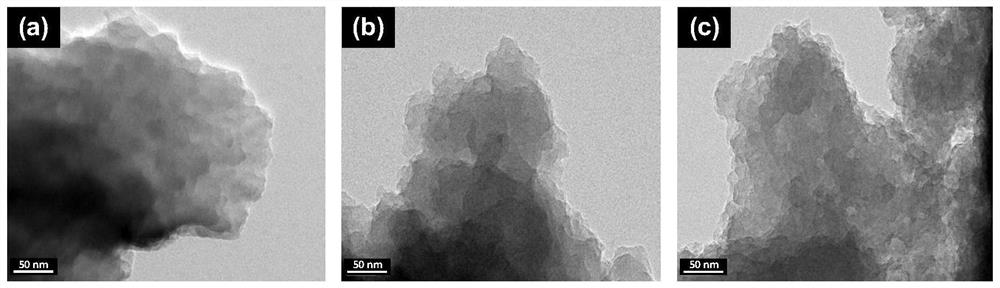

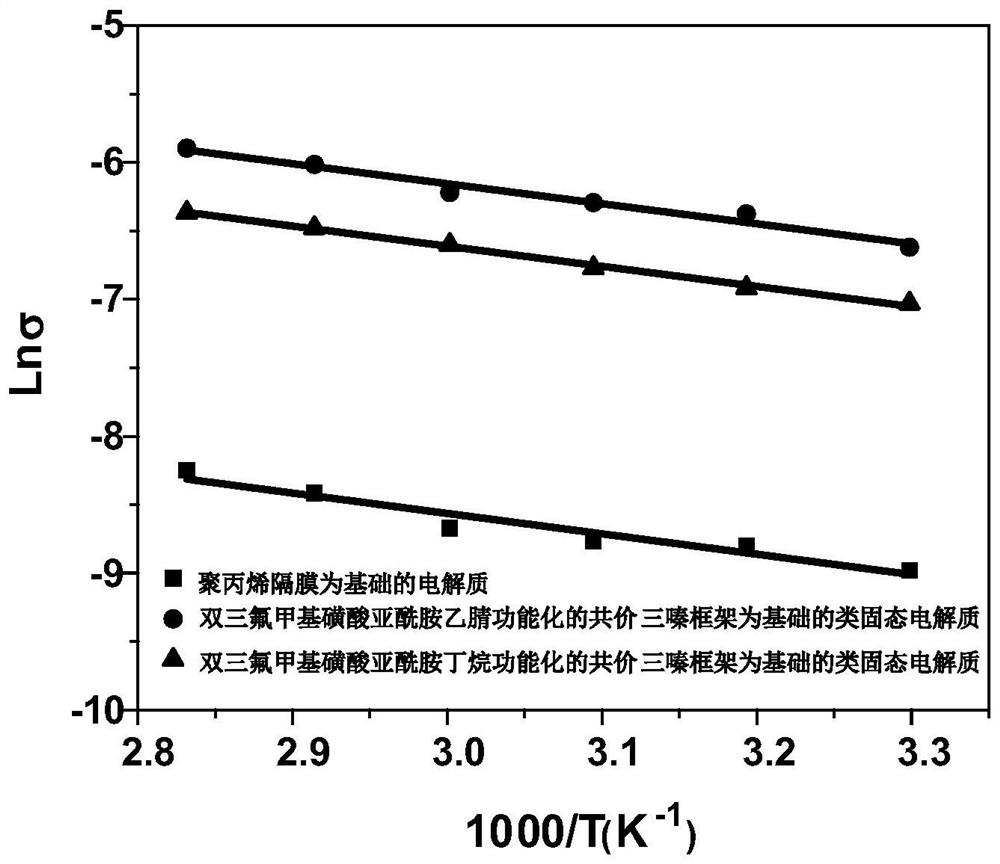

Embodiment 1

[0049] A solid-state-like electrolyte for lithium metal batteries comprising a covalent triazine framework functionalized with bistrifluoromethanesulfonimidobutane and an ionic liquid containing a lithium salt. The ionic liquid containing lithium salt is the mixed solution (concentration is 0.5mol / L, That is, the ratio of the amount of lithium salt substance to the volume of ionic liquid). The structure of the covalent triazine framework functionalized with bistriflate imidobutane is shown below:

[0050]

[0051] Among them, R is a butyl group, Y - for TFSI - .

[0052] This solid-like electrolyte for lithium-ion batteries is obtained by mechanically mixing and grinding a covalent triazine framework functionalized with bistrifluoromethanesulfonic acid imidobutane and an ionic liquid containing a lithium salt at a mass ratio of 6 / 1. , wherein the ionic liquid containing lithium salt is a mixed solution (0.5mol / L) of bistrifluoromethanesulfonic acid imide lithium and 1-b...

Embodiment 2

[0061] A solid-state-like electrolyte for lithium metal batteries comprising bistrifluoromethanesulfonimide acetonitrile functionalized covalent triazine framework and lithium salt-containing ionic liquid. The ionic liquid containing lithium salt is the mixed solution (0.5mol / L, i.e. The ratio of the amount of lithium salt substance to the volume of ionic liquid). The structure of the covalent triazine framework functionalized with bistrifluoromethanesulfonamide acetonitrile is shown below:

[0062]

[0063] Among them, R is acetonitrile, Y - for TFSI - .

[0064] This kind of solid-state electrolyte for lithium-ion batteries is obtained by mechanically mixing and grinding a covalent triazine framework functionalized with bistrifluoromethanesulfonic acid imide acetonitrile and an ionic liquid containing lithium salt at a mass ratio of 6 / 1. Wherein the ionic liquid containing lithium salt is a mixed solution (0.5mol / L) of bistrifluoromethanesulfonimide lithium and 1-buty...

Embodiment 3

[0073] A solid-state-like electrolyte for lithium metal batteries comprising bistrifluoromethanesulfonimide functionalized covalent triazine framework and lithium salt-containing ionic liquid. The ionic liquid containing lithium salt is the mixed solution (0.5mol / L, i.e. The ratio of the amount of lithium salt substance to the volume of ionic liquid). The structure of the bistrifluoromethanesulfonimide functionalized covalent triazine framework is schematically shown below:

[0074]

[0075] Among them, R is phenyl, Y - for TFSI - .

[0076] This kind of solid-state electrolyte for lithium-ion batteries is obtained by mechanically mixing and grinding the covalent triazine framework functionalized with bistrifluoromethanesulfonimide benzene and the ionic liquid containing lithium salt at a mass ratio of 6 / 1. Wherein the ionic liquid containing lithium salt is a mixed solution (0.5mol / L) of bistrifluoromethanesulfonimide lithium and 1-butyl-3-methimidazole-bistrifluoromet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com