A hemodialysis membrane for intervening oxidative stress and anticoagulation, its preparation method and application

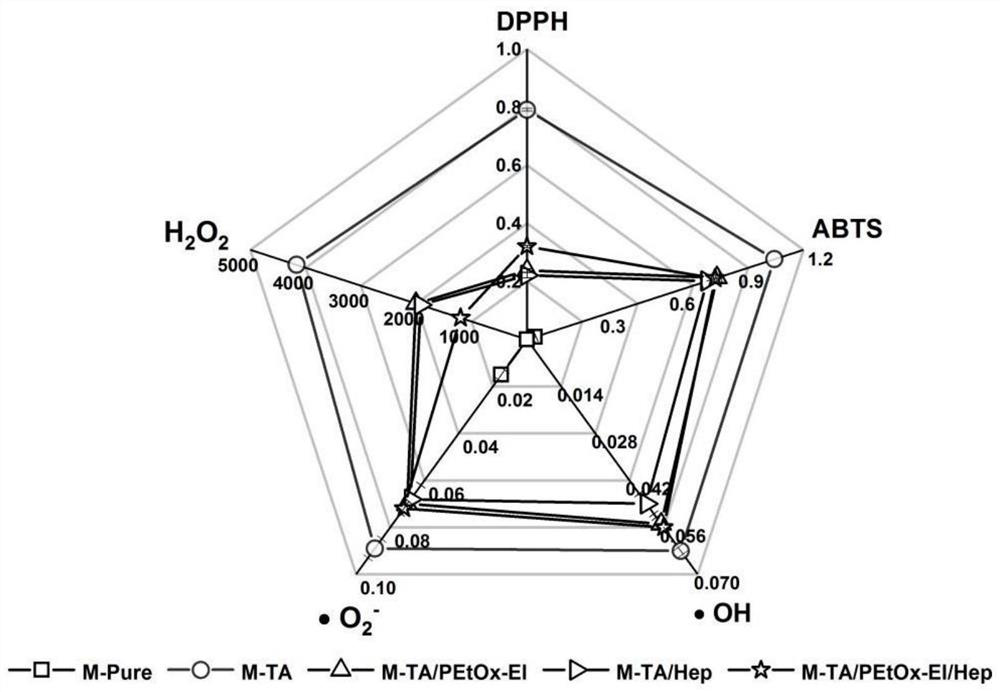

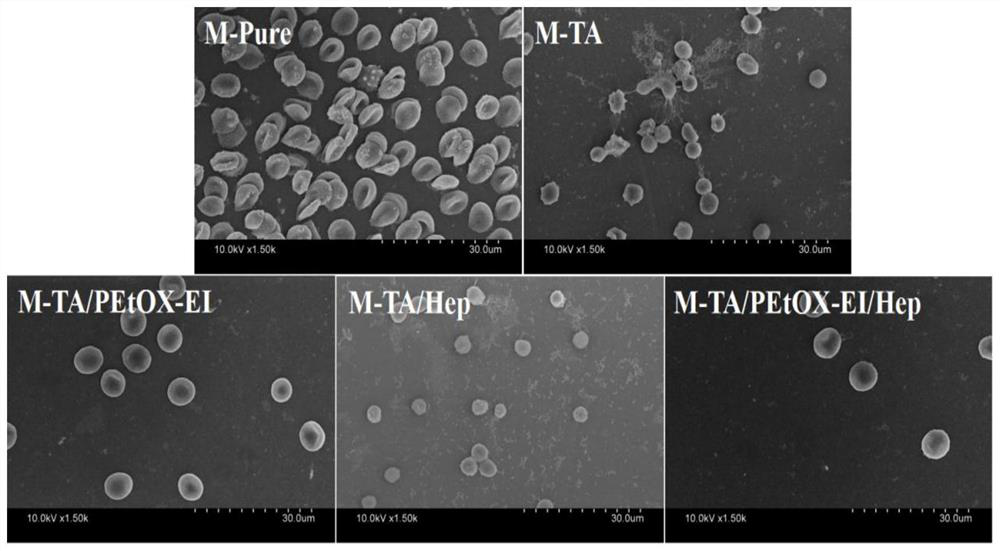

A technology of hemodialysis and oxidative stress, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problems of not being able to simultaneously play an anticoagulant effect, and not be able to improve the state of oxidative stress, and achieve practical value High, good biocompatibility, the effect of inhibiting oxidative stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The embodiment of the present invention proposes a method for preparing a hemodialysis membrane that interferes with oxidative stress and resists coagulation, including the following steps:

[0044] 1) preparing plant polyphenol mixed solution;

[0045] 2) preparing polyoxazoline (POZ) mixed solution;

[0046] 3) preparing an anticoagulant mixed solution;

[0047] 4) At a constant temperature, flow the above-mentioned plant polyphenol mixed solution through the hemodialysis membrane to obtain a plant polyphenol-modified hemodialysis membrane;

[0048] 5) At a constant temperature, the above-mentioned polyoxazoline mixed solution is passed through the above-mentioned plant polyphenol-modified hemodialysis membrane to obtain a plant polyphenol-POZ-modified hemodialysis membrane.

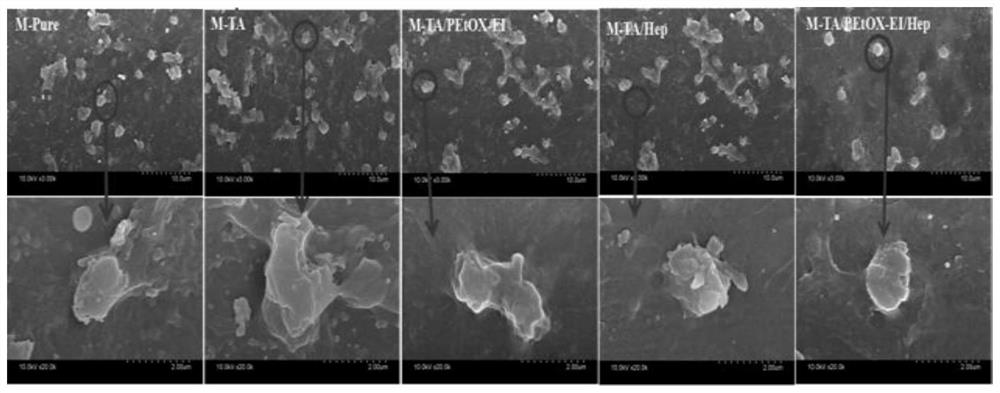

[0049] In the embodiment of the present invention, specific antioxidant substances, substances for improving blood compatibility and anticoagulant drugs are used to functionalize the membrane ...

Embodiment 1

[0087] Example 1 Preparation of plant polyphenol-POZ-anticoagulant modified hemodialysis membrane

[0088] 1) Hemodialysis membrane pretreatment: immerse the hemodialysis membrane in a beaker containing absolute ethanol for 0.5 h, then soak in deionized water for 0.5 h, and repeat this process 3 times. After treatment, the membrane was placed in deionized water for later use. Wherein, the hemodialysis membrane is a polyethersulfone membrane.

[0089] 2) Preparation of mixed solution of plant polyphenols: preparation of Tris buffer solution with a concentration of 1 g / L and a pH of 8.5. Add 2 g of plant polyphenols and 35.06 g of sodium chloride into 1 L of Tris buffer solution, stir for 5 minutes to fully dissolve, and obtain a uniform mixed solution of plant polyphenols; wherein, the plant polyphenols are tannic acid.

[0090] 3) Preparation of POZ mixed solution: preparation of a Tris buffer solution with a concentration of 1 g / L and a pH of 8.5. 3 g of 20% hydrolyzed P...

Embodiment 2

[0096] Example 2 Preparation of plant polyphenol-POZ-anticoagulant modified hemodialysis membrane

[0097]1) Hemodialysis membrane pretreatment: immerse the hemodialysis membrane in a beaker containing absolute ethanol for 0.6h, then soak in deionized water for 0.6h, and repeat this process 3 times; after treatment, the hemodialysis membrane The membrane was placed in deionized water until use. Wherein, the polymer membrane is a polysulfone membrane.

[0098] 2) Prepare plant polyphenol mixed solution: add plant polyphenol and metal salt to tris (Tris) buffer solution, stir for 3 minutes to obtain plant polyphenol mixed solution, make the plant polyphenol mixed solution of plant polyphenol The concentration is 2.5g / L, the final concentration of metal salt is 20g / L; the concentration of Tris buffer solution is 2g / L, and the pH is adjusted to 8.0 with HCl or NaOH aqueous solution with a concentration of 0.1mol / L; the plant polyphenol is caffeic acid , A mixture of cinnamic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com