Preparation method and application of MoO3 self-assembled hexagonal prism structure

A hexagonal prism and self-assembly technology, applied in the direction of molybdenum oxide/molybdenum hydroxide, etc., to achieve the effect of good uniformity, uniform size and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1.1 Add 1.5 g of ammonium molybdate tetrahydrate (AHM) to a mixed solvent of 30 mL of water, 0.5 mL of isopropanol, and 0.10 mL of 1,3,5-trimethylbenzene, and stir for 0.5 h;

[0028]1.2 Add 0.20 g of sodium dodecyl sulfate (SDS), 0.04 g of polyether F127, 0.002 g of PVP K-30, and 0.007 g of dodecylamine to the above solution and stir for 0.5 h, then add 1.2 mL Nitric acid was stirred for 0.5 h to form a mixed solution.

[0029] 1.3 Transfer the obtained mixed solution to a reaction kettle, then put it into an oven, set the parameters as follows: 160°C, 14h, then centrifuge with water and ethanol, wash, and dry.

[0030] 1.4 Place the precursor in a muffle furnace, and raise the temperature from room temperature to 500 °C at a rate of 1 °C / min in an air atmosphere, keep the temperature for 2 h, and obtain the product after the sample is cooled with the furnace.

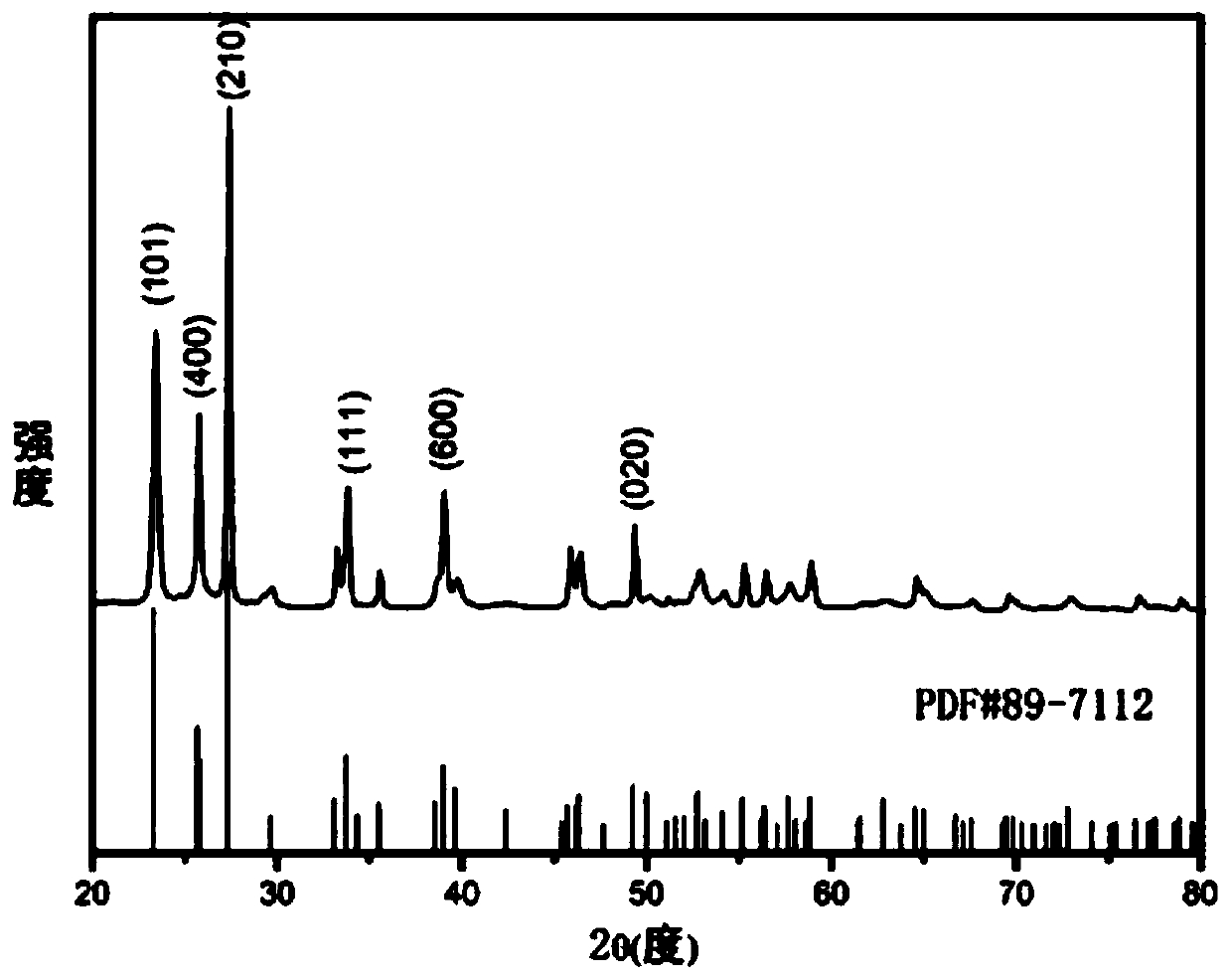

[0031] The XRD result of the product is as follows figure 1 As shown, it can be seen from the figure that ...

Embodiment 2

[0033] 2.1 Add 0.85 g of AHM to a mixed solvent of 29 mL of water, 0.4 mL of isopropanol, and 0.10 mL of 1,3,5-trimethylbenzene, and stir for 0.5 h;

[0034] 2.2 Add 0.10 g of SDS, 0.031 g of polyether F127, 0.0018 g of PVP K-30, and 0.005 g of dodecylamine to the above solution and stir for 0.5 h, then add 1.2 mL of nitric acid and stir for 0.5 h to form a mixed solution.

[0035] 2.3 Transfer the obtained mixed solution to a reaction kettle, then put it into an oven, set the parameters as follows: 150°C, 14h, then centrifuge with water and ethanol, wash, and dry.

[0036] 2.4 Place the precursor in a muffle furnace, and raise the temperature from room temperature to 480 °C at a rate of 1 °C / min in an air atmosphere, and keep the temperature for 3 h. After the sample is cooled with the furnace, the product is obtained.

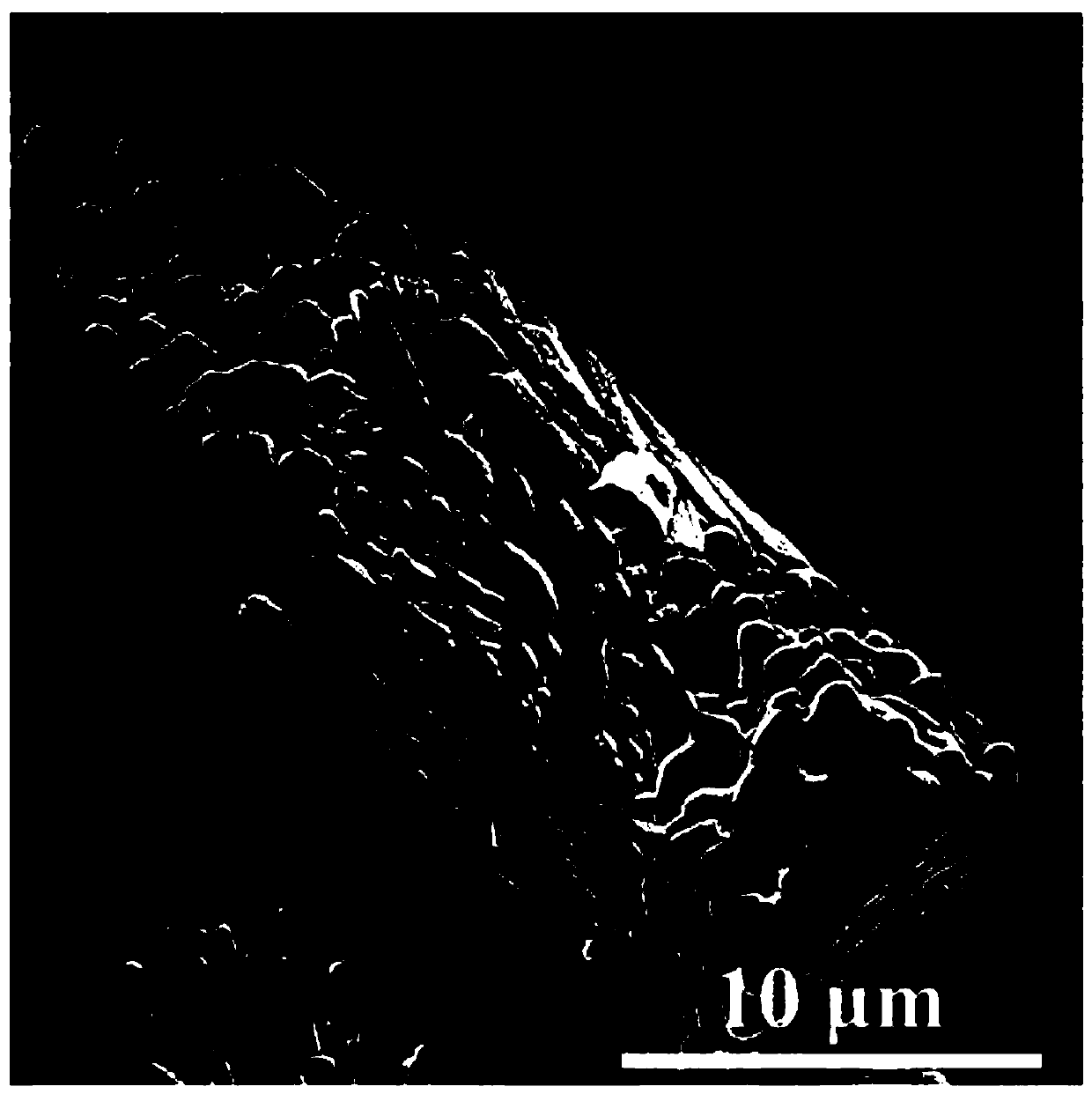

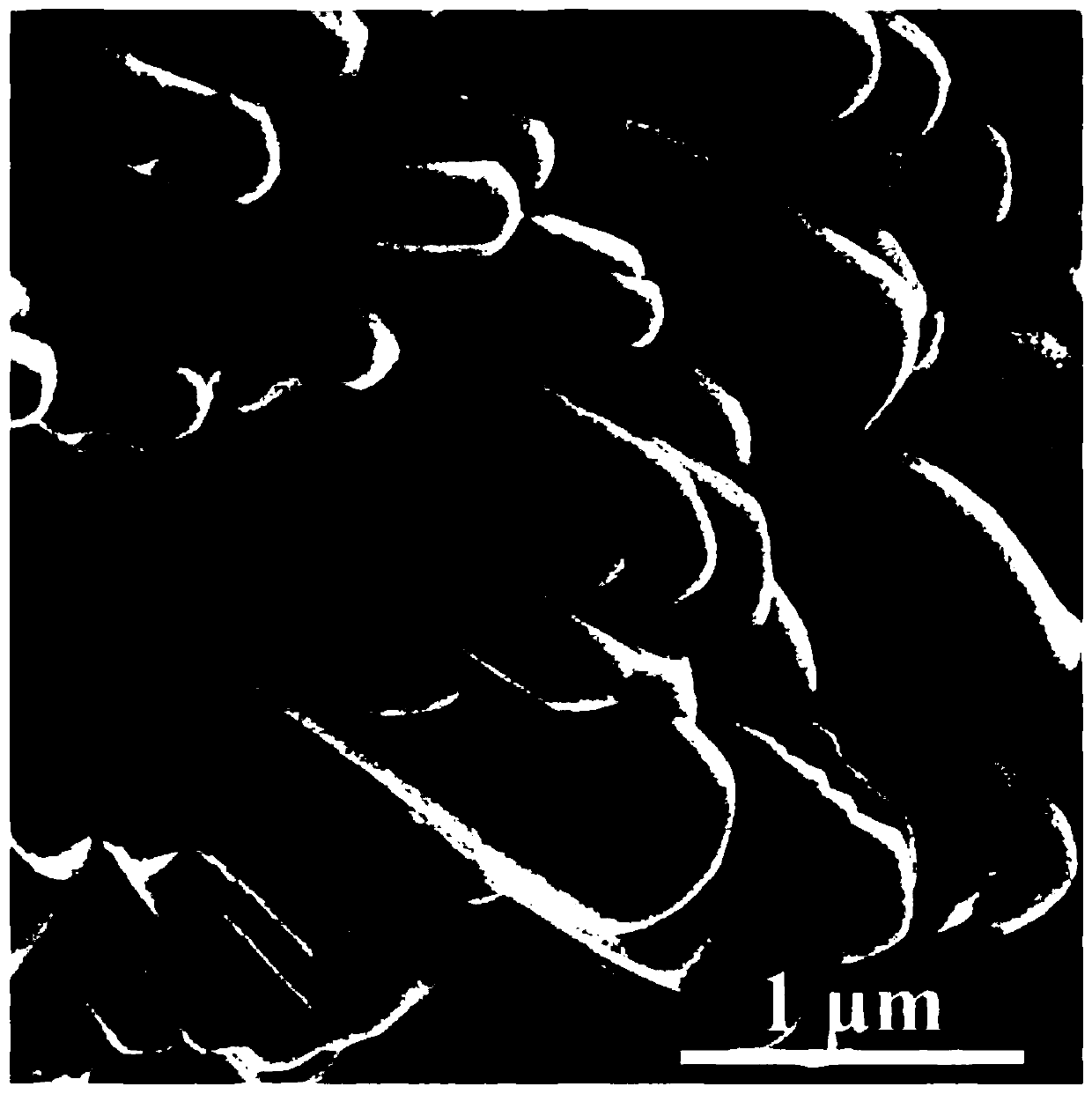

[0037] 2.5 The size-adjustable plate-like MoO is obtained after the sample is cooled with the furnace 3 Self-assembled hexagonal prism structure, the side ...

Embodiment 3

[0039] 3.1 Add 0.95 g of AHM to a mixed solvent of 28 mL of water, 0.7 mL of isopropanol, and 0.12 mL of 1,3,5-trimethylbenzene, and stir for 0.5 h;

[0040] 3.2 Add 0.13 g of SDS, 0.034 g of polyether F127, 0.0014 g of PVP K-30, and 0.004 g of dodecylamine to the above solution and stir for 0.5 h, then add 1.2 mL of nitric acid and stir for 0.5 h to form a mixed solution.

[0041] 3.3 Transfer the obtained mixed solution to a reaction kettle, then put it into an oven, set the parameters: 160 °C for 12 hours, then centrifuge with water and ethanol, wash, and dry.

[0042] 3.4 Place the precursor in a muffle furnace, and raise the temperature from room temperature to 530 °C at a rate of 1.5 °C / min in an air atmosphere, and keep the temperature for 2 h. After the sample is cooled with the furnace, the product is obtained.

[0043] The size-adjustable plate-like MoO was obtained after the sample was cooled in the furnace 3 Self-assembled hexagonal prism structure, the side leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com