Flexible heat-resistant ceramizable silicone rubber composite material and preparation method thereof

A technology of vitrified silicone rubber and composite materials, applied in the field of rubber materials, can solve the problems of low thermal stability, achieve good mechanical properties, easy processing and molding, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

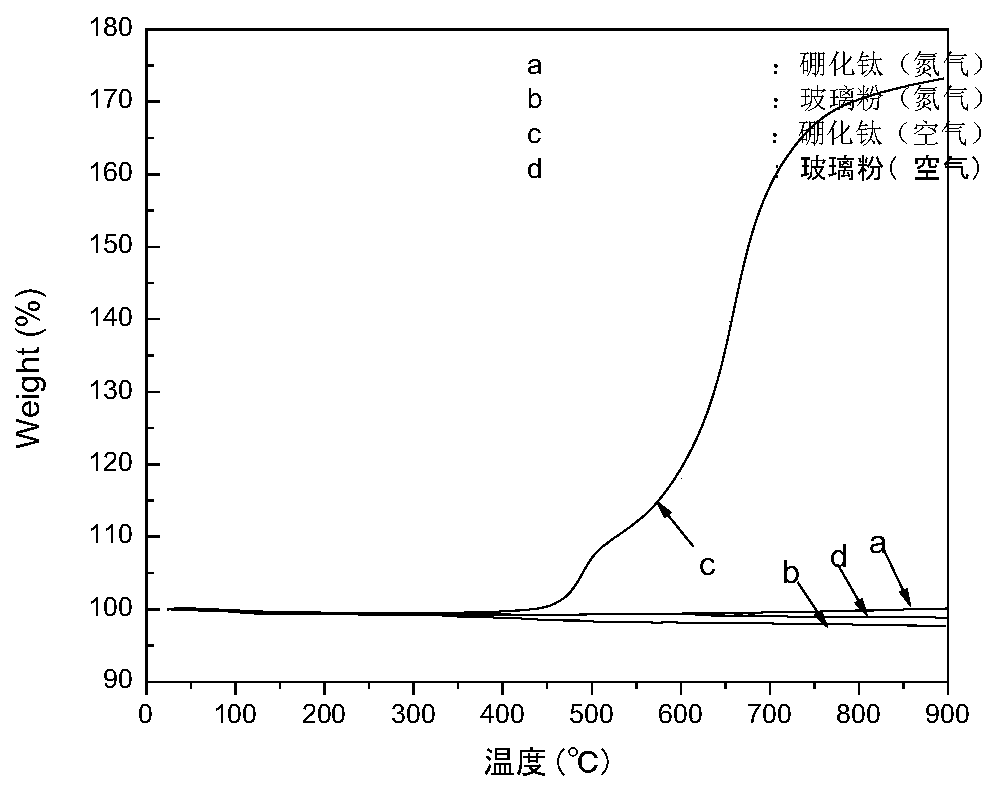

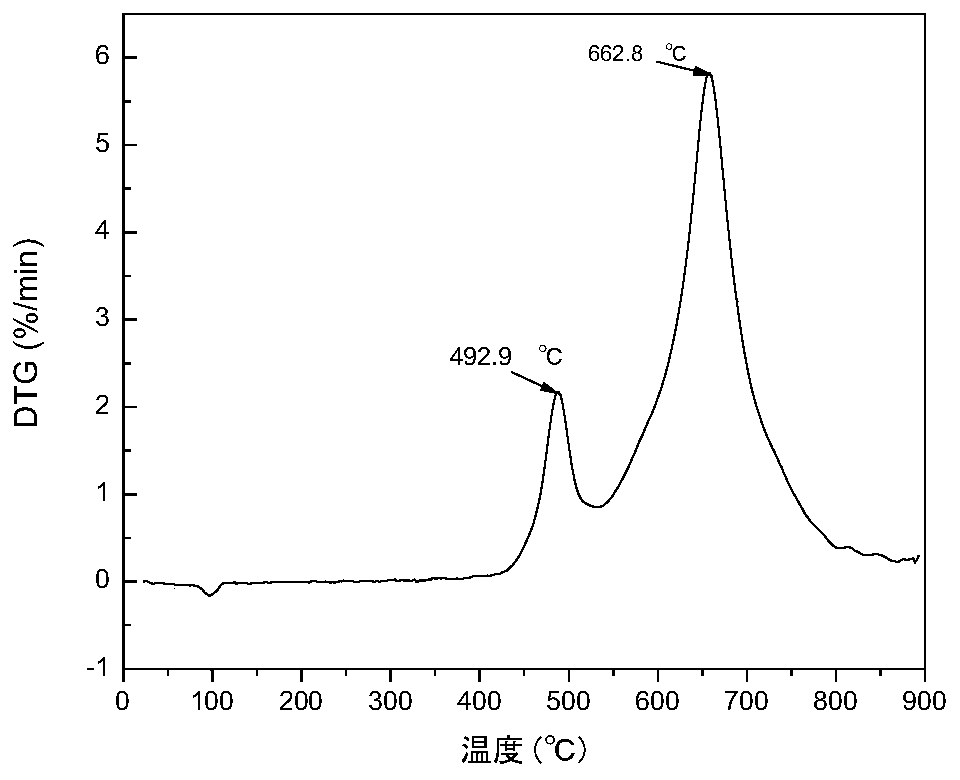

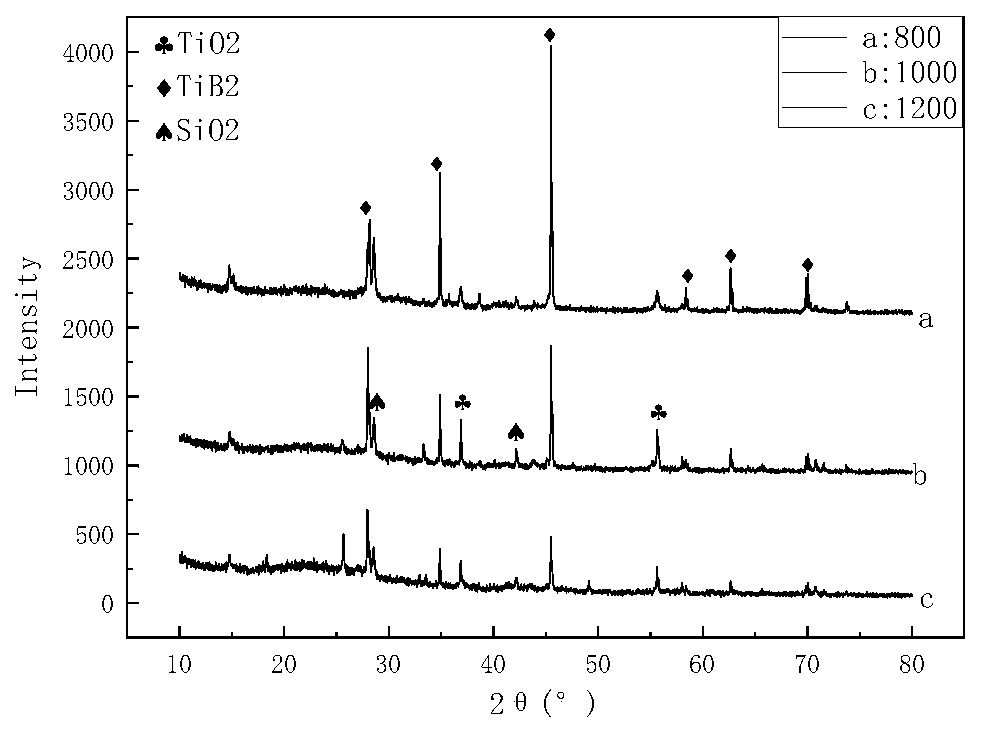

[0037] A flexible heat-resistant ceramizable silicone rubber composite material, comprising the following components in parts by weight: methyl vinyl silicone rubber: 100 parts, fumed white carbon black: 25 parts, titanium boride powder: 40 parts, carbonized Mixture of boron and low-melting glass powder: 20 parts, bis-pentasulfurizing agent: 2 parts. Among them, the specific gravity of boron carbide is 2.52g / cm 3 , the melting point is 2400-2500°C; the melting point of low-melting point glass powder is 400-600°C, the particle size is 4.6-5.5um, SiO 2 The content is 52.04%; the average particle size of titanium boride powder is 3-5um.

[0038] The preparation of the above-mentioned flexible heat-resistant ceramizable silicone rubber composite material specifically includes the following steps:

[0039] 1) According to the above component formula, after kneading methyl vinyl silicone rubber in a two-roll mill for 3 to 5 minutes, add fumed silica into the two-roll mill and knea...

Embodiment 2

[0055] A flexible heat-resistant ceramizable silicone rubber composite material, comprising the following components in parts by weight: methyl vinyl silicone rubber: 100 parts, fumed white carbon black: 25 parts, titanium boride powder: 40 parts, carbonized The mixture of boron and low-melting glass powder: 20 parts, the mixture of alumina fiber and chopped carbon fiber: 15 parts, bis-pentasulfurizing agent: 2 parts. Among them, the specific gravity of boron carbide is 2.52g / cm 3 , the melting point is 2400-2500°C; the melting point of low-melting point glass powder is 400-600°C, the particle size is 4.6-5.5um, SiO 2 The content is 52.04%; the average particle size of titanium boride powder is 3-5um; the diameter of chopped carbon fiber monofilament is 5-7um, the length is 1-10mm, and the density is 1-2g / cm 3 .

[0056] The preparation of the above-mentioned flexible heat-resistant ceramizable silicone rubber composite material specifically includes the following steps:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com