A kind of ultra-hydrophobic ultraviolet curing coating and preparation method thereof

A technology for curing coatings and ultraviolet light, applied in the field of coatings, can solve the problems of inability to meet the requirements of super-hydrophobicity and low water contact angle, and achieve the effect of increasing hydrophobicity and improving hydrophobicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

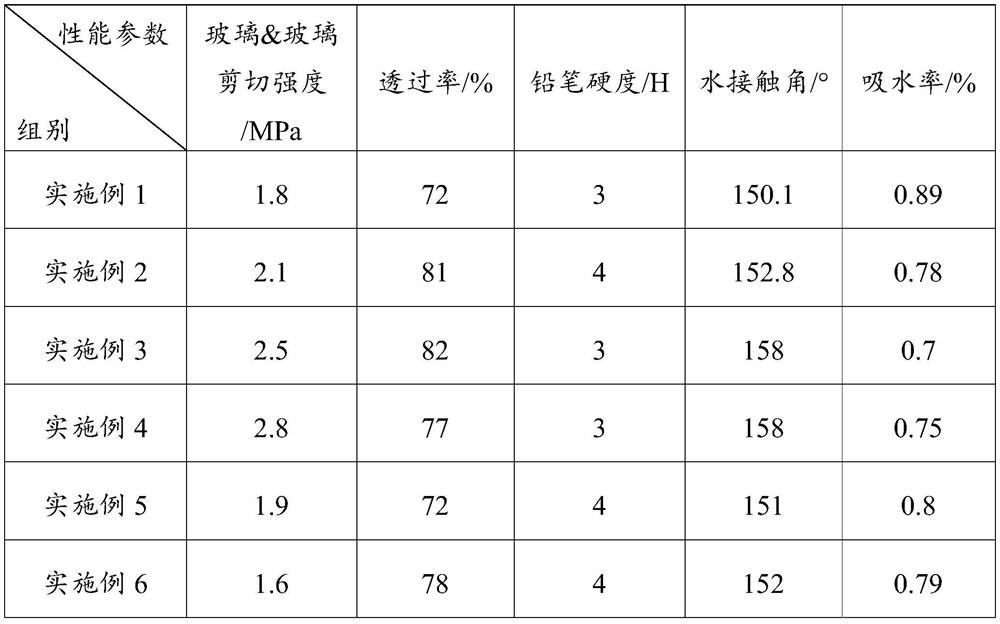

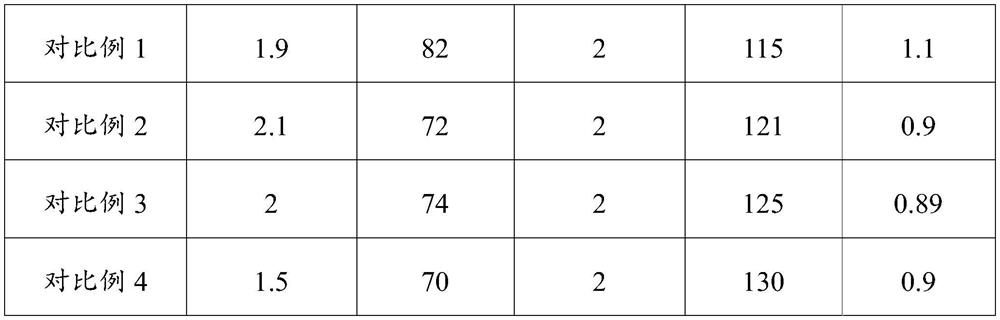

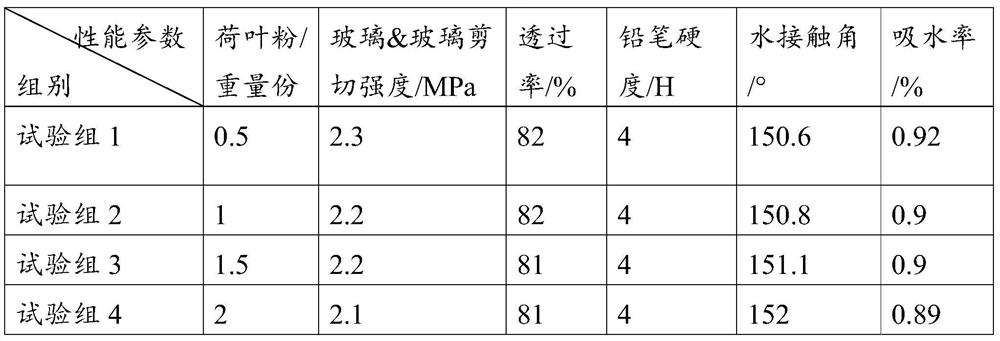

Examples

Embodiment 1

[0039] An embodiment of the UV-curable coating of the present invention, the UV-curable coating in this embodiment comprises the following components in parts by weight: 15 parts of fluorine-containing acrylate polymer, 40 parts of photo-curable resin, acrylate reactive monomer 37 parts of body, 0.7 parts of leveling agent, 0.8 parts of coupling agent, 5 parts of photoinitiator and 1.5 parts of lotus leaf powder;

[0040] Wherein, the photocurable resin is polyurethane acrylate; the acrylate active monomer is composed of the following components by weight: 20 parts of isobornyl acrylate, 15 parts of isooctyl acrylate and 1,6-hexanediol diol 2 parts of acrylate; the leveling agent is an acrylate leveling agent; the coupling agent is a KH550 coupling agent; the photoinitiator is composed of the following components by weight: 2-phenylbenzyl-2 - 1 part of dimethylamine-1-(4-morpholinebenzylphenyl) butanone and 4 parts of 1-hydroxy-cyclohexyl-phenylmethanone.

[0041] The prepara...

Embodiment 2

[0053] An embodiment of the UV-curable coating of the present invention, the UV-curable coating in this embodiment comprises the following components in parts by weight: 10 parts of fluorine-containing acrylate polymer, 45 parts of photo-curable resin, acrylate reactive monomer 36 parts of body, 0.5 parts of leveling agent, 1.5 parts of coupling agent, 6.5 parts of photoinitiator and 2.5 parts of lotus leaf powder;

[0054] Wherein, the photocurable resin is composed of the following components by weight: 20 parts of polyurethane acrylate and 25 parts of epoxy acrylate; the acrylate reactive monomer is composed of the following components by weight: 2-phenoxy 22 parts of ethyl acrylate, 6 parts of cyclotrimethylolpropane methylal acrylate and 8 parts of isooctyl acrylate; the leveling agent is a silicone leveling agent with a primary hydroxyl group; the coupling agent It is a KH560 coupling agent; the photoinitiator consists of the following components by weight: 3.5 parts of ...

Embodiment 3

[0057] An embodiment of the UV-curable coating of the present invention, the UV-curable coating in this embodiment comprises the following components in parts by weight: 10 parts of fluorine-containing acrylate polymer, 35 parts of photo-curable resin, acrylate reactive monomer 35 parts of body, 1 part of leveling agent, 5 parts of coupling agent, 6 parts of photoinitiator and 8 parts of lotus leaf powder;

[0058] Wherein, the photocurable resin is polyester acrylate; the acrylate active monomer is hydroxyethyl acrylate; the leveling agent is a vinyl group-containing silicone leveling agent; the coupling agent is KH570 coupling agent; the photoinitiator consists of the following components by weight: 2 parts of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 2-hydroxyl-2-methyl-1 -2 parts of phenyl-1-propanone and 2 parts of phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide.

[0059] The preparation method of the fluorine-containing acrylate polymer and the preparation method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com