Negative electrode material for lithium ion secondary battery, negative electrode sheet, and lithium ion secondary battery

A negative electrode material and secondary battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of poor cycle stability of lithium-ion secondary batteries, complex research on lithium supplementation, doping of lithium organic solutions, etc., to achieve Reduce the cost of process manufacturing and environmental control, solve the problem of capacity fading, and solve the effect of poor rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

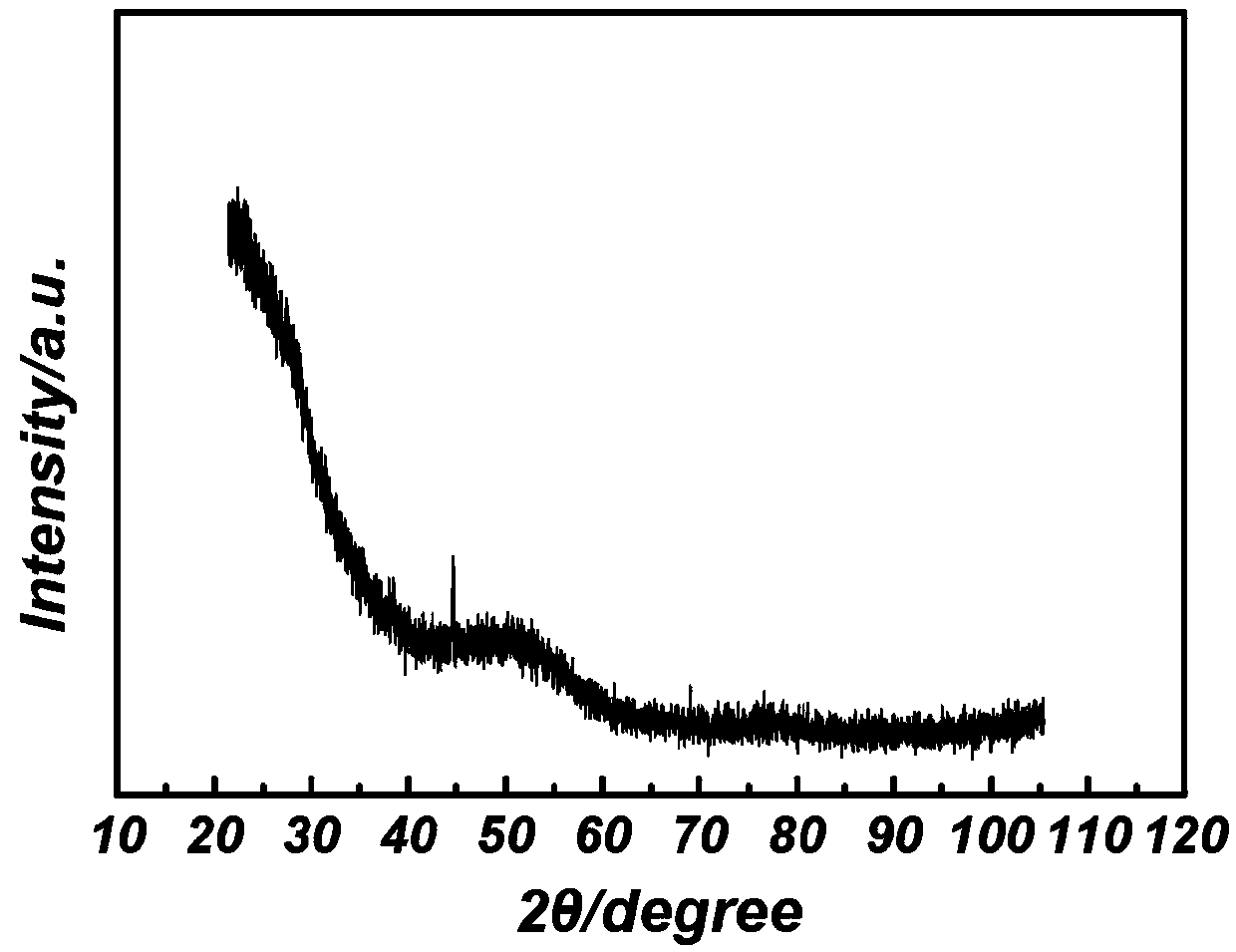

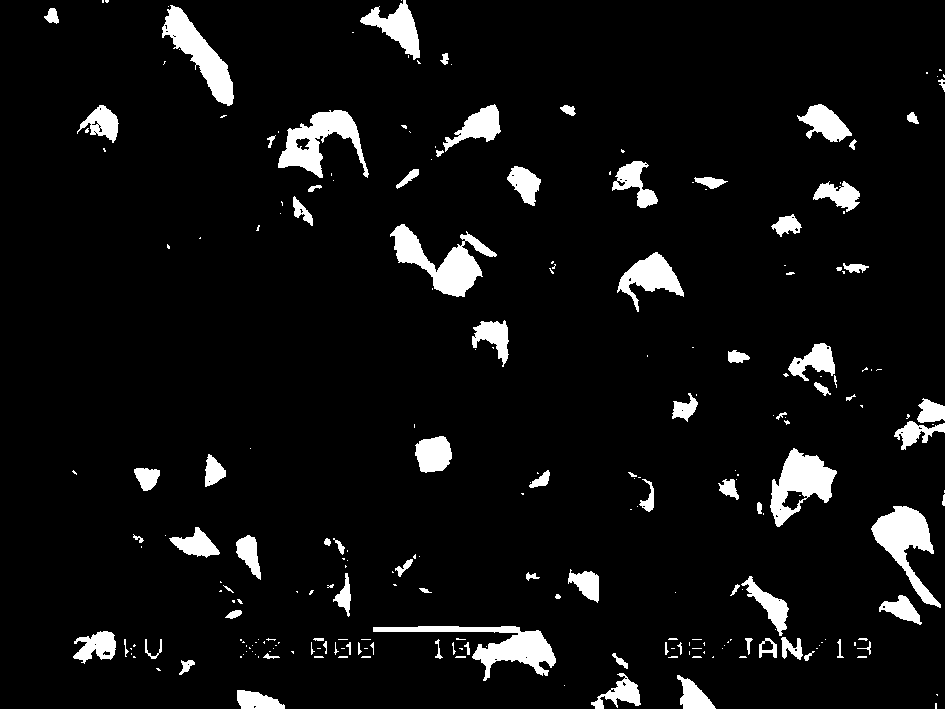

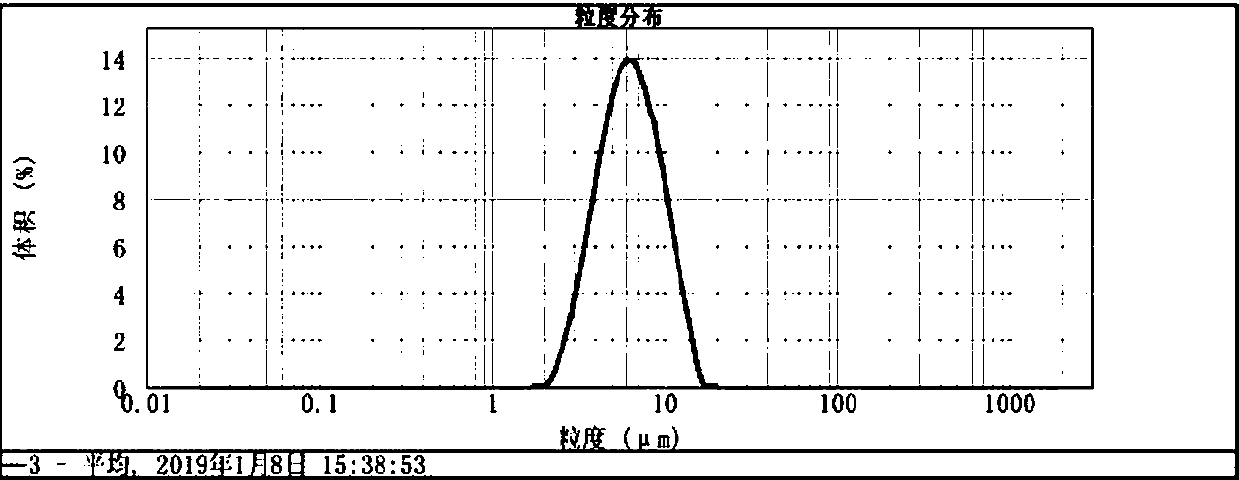

[0032] In the present invention, the preparation method of the silicon-based negative electrode active material includes the following steps: adding a certain proportion of the silicon-oxygen material SiO x Grinding together with the carbon-based active material and then adding to a classifier for classification to obtain a silicon-based negative electrode active material with a narrow particle size distribution. The silicon-based negative electrode active material has D10 ≥ 2 μm and D90 ≤ 5 μm.

[0033] In the present invention, the silicon-based negative electrode active material is made of silicon-oxygen material SiO x And carbon-based active substances are obtained after crushing and then grading. Due to the mechanical force generated by Van der Waals force and the crushing process, the silicon-oxygen material SiO x The surface of the particles will adsorb and coat carbon-based active substances, forming a silicon-oxygen material SiO x The core-shell structure is the core a...

Embodiment 1

[0061] The negative electrode material of lithium ion secondary battery includes negative electrode active material, negative electrode conductive agent, negative electrode binder and solvent; said negative electrode active material includes silicon-based negative electrode active material and graphite negative electrode active material.

[0062] Wherein, the silicon-based negative electrode active material is silicon-oxygen material SiO x as the core, and the surface is coated with carbon-based active materials, wherein, 0.5≤x≤1.6. The preparation method of the silicon-based negative electrode active material comprises the following steps: SiO x (0.8≤x≤1.5) Mechanical jaw crusher crushed to SiO with a median particle size of 1000-2000μm x particles, 100 parts of SiO obtained x Particles and 5 parts of carbon-based active substances with a median particle size of 3-5 μm are placed in a ball mill containing 4mm agate balls and n-hexane solvent for high-speed ball milling; aft...

Embodiment 2

[0066]The negative electrode sheet of the lithium ion secondary battery includes a negative electrode current collector and a negative electrode active layer coated on the surface of the negative electrode current collector.

[0067] The preparation method of the negative electrode sheet is as follows: use the negative electrode material in Example 1 to coat the slurry on both sides of the negative electrode current collector with a coating device with a die, dry it with a hot air drying device, and finally compress it with a roller press Forming; wherein, a negative electrode current collector with a thickness of 10 μm is used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com